Research Success Stories

Interfacial Tailoring of Polyether Sulfone-Modified Silica Mixed Matrix Membranes for CO2 Separation

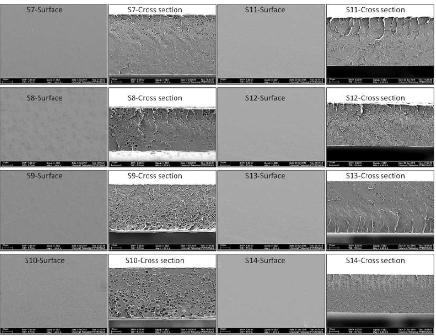

In this work, in situ polymerization of modified sol-gel silica in a polyether sulfone matrix is presented to control the interfacial defects in organic-inorganic composite membranes. Polyether sulfone polymer and modified silica are used as organic and inorganic components of mixed matrix membranes (MMM). The membranes were prepared with different loadings (2, 4, 6, and 8 wt.%) of modified and unmodified silica. The synthesized membranes were characterized using Field emission electron scanning microscopy, energy dispersive X-ray, Fourier transform infrared spectroscopy, thermogravimetric analyzer, and differential scanning calorimetry. The performance of the membranes was evaluated using a permeation cell set up at a relatively higher-pressure range (5-30 bar). The membranes appear to display ideal morphology with uniform distribution of particles, defect-free structure, and absence of interfacial defects such as voids and particle accumulations. Additionally, the CO2/CH4 selectivity of the membrane increased with the increase in the modified silica content. Further comparison of the performance indicates that PES/modified silica MMMs show a promising feature of commercially attractive membranes. Therefore, tailoring the interfacial morphology of the membrane results in enhanced properties and improved CO2 separation performance.

Posted on: November 2022

Authored: Hilmi Mukhtar

Carbon nanotube (CNT) is a prominent material for gas separation due to its inherent smoothness of walls, allowing rapid transport of gases compared to other inorganic fillers. It also possesses high mechanical strength, enabling membranes to operate at high pressure. Although it has superior properties compared to other inorganic fillers, preparation of CNTs into a polymer matrix remains challenging due to the strong van der Waals forces of CNTs, which lead to agglomeration of CNTs. To utilize the full potential of CNTs, proper dispersion of CNTs must be addressed. In this paper, methods to improve the dispersion of CNTs using functionalization methods were discussed. Fabrication techniques for CNT mixed-matrix membrane (MMM) nanocomposites and their impact on gas separation performance were compared. This paper also reviewed the applications and potential of CNT MMMs in gas separation.

Posted on: May 2022

Authored: Hilmi Mukhtar

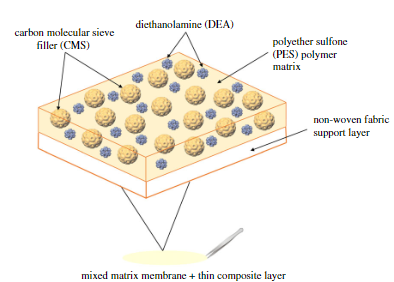

The key challenge in the synthesis of composite mixed matrix membrane (MMMs) is the incompatible membrane fabrication using porous support in the dry-wet phase inversion technique. The key objective of this research is to synthesize thin composite ternary (amine) mixed matrix membranes on microporous support by incorporating 10 wt% of carbon molecular sieve (CMS) and 5-15 wt% of diethanolamine (DEA) in polyethersulfone (PES) dope solution for the separation of carbon dioxide (CO 2 ) from methane (CH 4 ) at high-pressure applications. The developed membranes were evaluated for their morphological structure, thermal and mechanical stabilities, functional groups, as well as for CO 2 -CH 4 separation performance at high pressure (10-30 bar). The results showed that the developed membranes have asymmetric structure, and they are mechanically strong at 30 bar. This new class of PES/CMS/DEA composite MMMs exhibited improved gas permeance compared to pure PES composite polymeric membrane. CO 2 -CH 4 perm-selectivity enhanced from 8.15 to 16.04 at 15 wt% of DEA at 30 bar pressure. The performance of amine composite MMMs is theoretically predicted using a modified Maxwell model. The predictions were in good agreement with experimental data after applying the optimized values with AARE % = ~less than 2% and R 2 = 0.99.

Posted on: September 2020

Authored: Hilmi Mukhtar