Research Success Stories

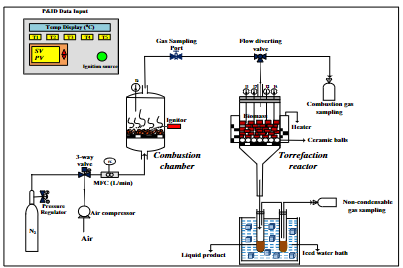

Torrefaction is a well-known method to thermally treats biomass at lower temperature range (200 to 300 Celcius) under inert atmosphere. However, the continuous supply of pure inert gas on large scale resist the commercialisation of this process. To investigate the effect of combustion gas (flue gas) on torrefaction performance of oil palm fronds leaves (OPFL) and stems (OPFS), both samples were torrefied at 200 Celcius for 30 min in a vertical tubular reactor under the atmosphere of combustion gas produced from wood pellets and nitrogen (inert) gas. The major components of combustion gas were nitrogen and carbon dioxide (total 76 vol% to 83 vol%) and the rest of the mixture contained oxygen, carbon monoxide and hydrogen. The effects of combustion gas atmosphere on the torrefaction performance of OPFL and OPFS including solid yield, calorific value, energy yield, proximate and ultimate compositions were investigated and compared with those of nitrogen atmosphere torrefaction. The combustion gas torrefaction resulted in lower solid yield and energy yield but with higher energy density (calorific value, carbon content) as compared to nitrogen torrefaction. Under combustion gas atmosphere, torrefaction of OPF stems gave higher solid yield (84.66 wt%) than OPF leaves (80.85 wt%) while solid yield of both samples under nitrogen atmosphere was almost same (88.02 wt% and 88.54 wt%). The increase in solid conversion under combustion atmosphere was caused by the partial oxidation took place in the presence of oxygen. Non-condensable gases at the outlet of the torrefaction reactor contained carbon dioxide and carbon monoxide.

Posted on: March 2020

Authored: Masaharu Komiyama