Research Success Stories

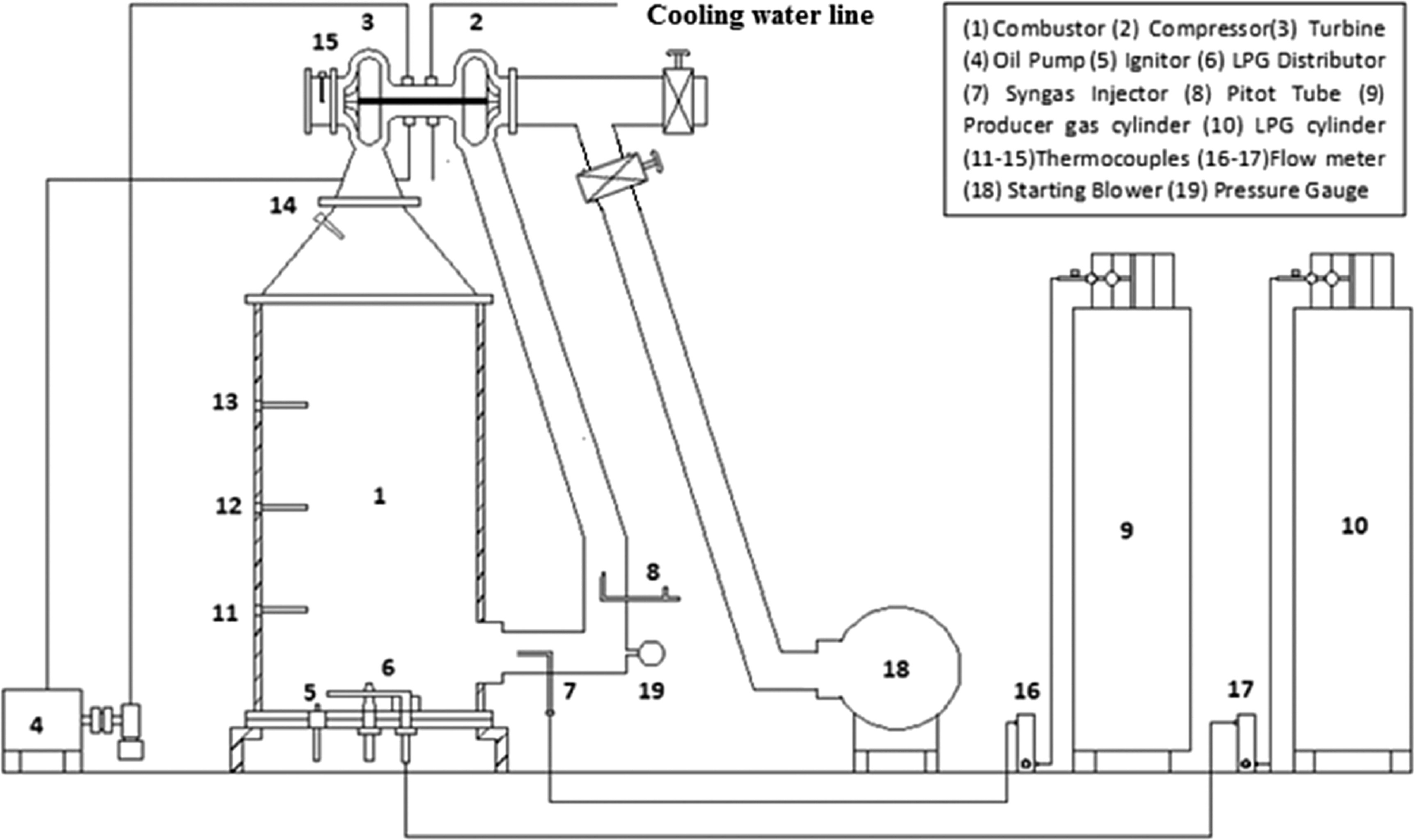

Producer gas from biomass gasification has a potential to cover a considerable part of power production in the future, the availability and variety of biomass put it as the fourth energy resource. The use of producer gas fuels in gas turbine engines can help mitigating problems related to fossil fuels depletion, emissions and biomass waste disposal. In this work, the effect of the staged combustion of a simulated low calorific value producer gas fuels on the performance and emissions of a single shaft micro gas turbine was investigated experimentally. In order to perform the experiments, the micro gas turbine system was characterized first with the liquefied petroleum gas (LPG) and then tested with two producer gas fuels, producer gas1 (10.53% H2, 24.94% CO, 2.03% CH4, 12.80% CO2, and 49.70% N2) and producer gas2 (21.62% H2, 32.48% CO, 3.72% CH4, 19.69% CO2, and 22.49% N2) in a dual fuel mode. Two injection methods were proposed and tested for producer gases including radially and axially injection. The tests were examined in terms of LPG fuel replacement, turbine entrance temperature, combustor efficiency, turbine efficiency, and emission characteristics at different LPG fuel replacement ratios. The study showed stable operation with a maximum LPG replacement of 42% and 56% for the radially injected producer gas1 and producer gas2, respectively. While for the axially injected producer gas fuels, the maximum achieved LPG replacement ratio was 38% and 52% for producer gas1 and producer gas2, respectively. A relatively higher efficiencies for the combustor and turbine with a remarkable reduction in NOx emissions were achieved when LPG fuel was replaced with producer gas fuels. On the other hand CO emissions were increased for both injection methods.

Posted on: February 2017

Authored: Shaharin Anwar Sulaiman

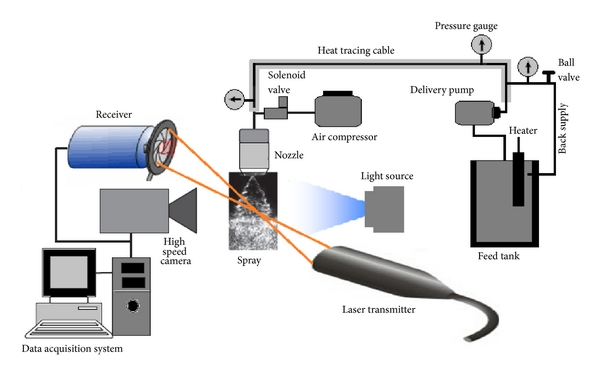

The hot water sprays are an important part of many industrial processes, where the detailed knowledge of physical phenomena involved in jet transportation, interaction, secondary breakup, evaporation, and coalescence of droplets is important to reach more efficient processes. The objective of the work was to study the water spray jet breakup dynamics, vortex cloud formation, and droplet size distribution under varying temperature and load pressure. Using a high speed camera, the spray patterns generated by axisymmetric full cone nozzles were visualized as a function water temperature and load pressure. The image analysis confirmed that the spray cone angle and width do not vary significantly with increasing Reynolds and Weber numbers at early injection phases leading to increased macroscopic spray propagation. The formation and decay of semitorus like vortex clouds were also noticed in spray structures generated at near water boiling point temperature. For the nozzle with smallest orifice diameter (1.19 mm), these vortex clouds were very clear at 90°C heating temperature and 1 bar water load pressure. In addition, the sauter mean diameter (SMD) of the spray droplets was also measured by using Phase Doppler Anemometry (PDA) at different locations downstream of the nozzle exit. It was noticed that SMD varies slightly w.r.t. position when measured at room temperature whereas at higher temperature values, it became almost constant at distance of 55 mm downstream of the nozzle exit.

Posted on: November 2013

Authored: Shaharin Anwar Sulaiman

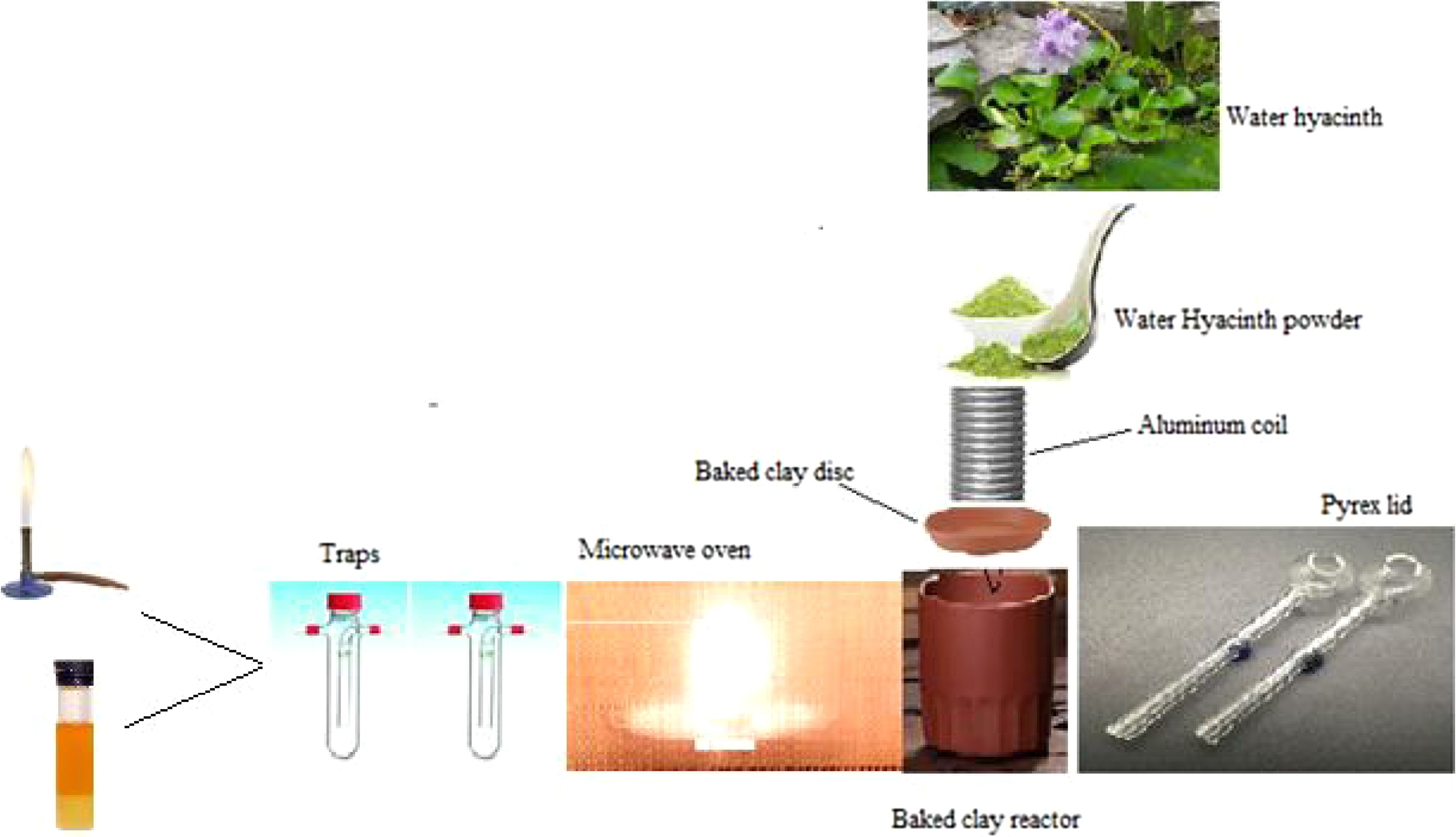

Metal objects spark in the microwaves, exposing metals to melting point temperatures. The resulting heat can be utilized for the pyrolysis of biomass into upgraded bio oil. In this work pyrolysis was carried out both in the presence and absence of catalyst and the upgradation of bio oil was found the combine action of microwave heating, microwave effects and the catalytic activity of cement. Catalytic pyrolysis of biomass was carried out by mixing powdered biomass with fine powder of cement and placing the resulting mixture in an aluminum coil located in the baked clay reactor followed by its exposure to the microwaves. In this process aluminum coil was used as microwave receiving and heat generating antenna. All these experiments were carried out in a modified domestic microwave oven. The amount of product fractions like bio-oil, biogas and biochar was determined in terms of the mass of catalyst, time of reaction and the gauge of aluminum wire used for the preparation of coil. The bio oil obtained under the optimum conditions was analyzed using Gas chromatography mass spectrometry and the gaseous product was analyzed using chemical tests. Significant difference was observed in the chemical composition of bio oils prepared by catalytic and non-catalytic processes. Further, the oxygen contents of both types of the bio oil were found less than those to be obtained by conventional pyrolysis.

Posted on: January 2018

Authored: Shaharin Anwar Sulaiman

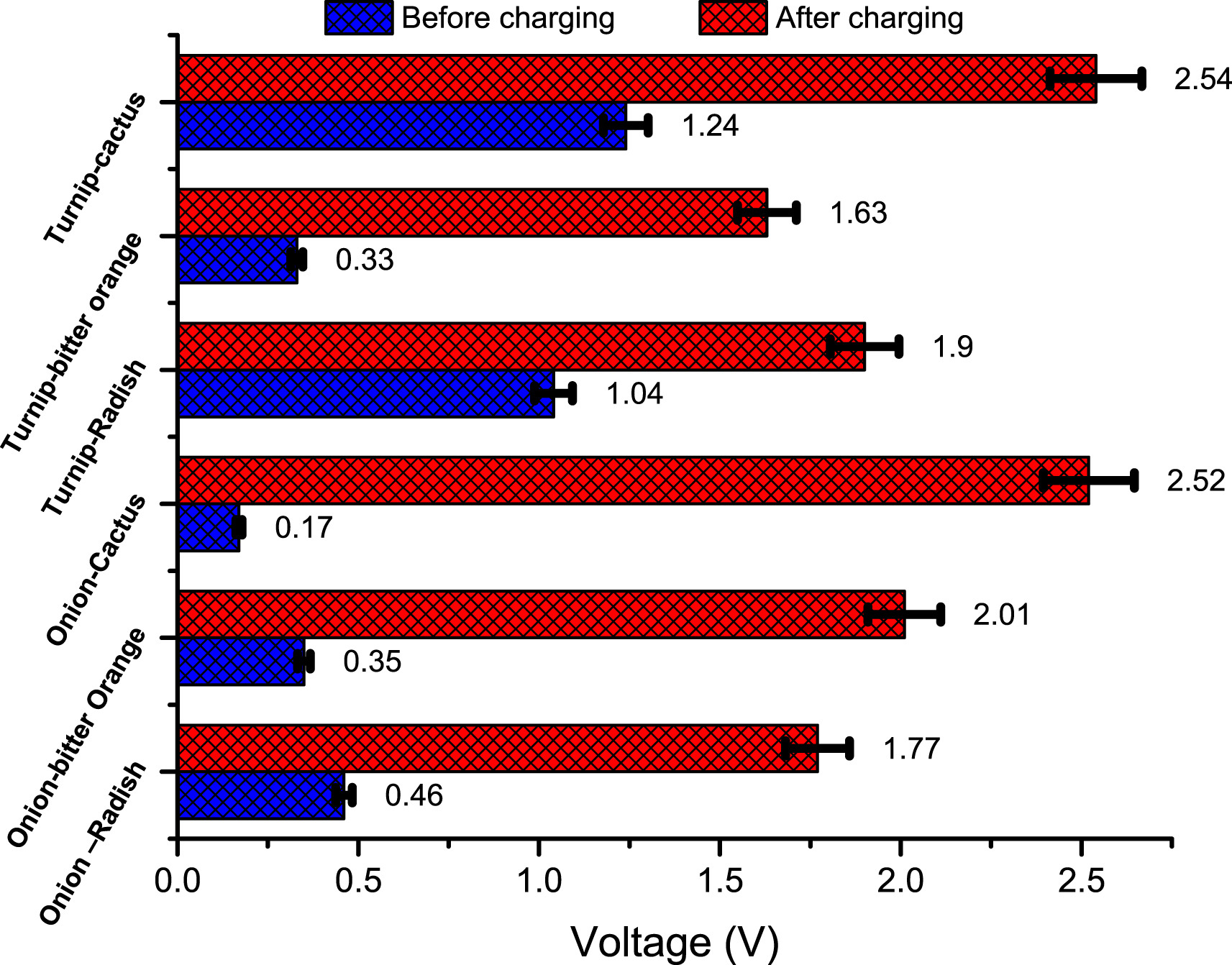

This work is focused on energy harvesting and energy storage through renewable sources. In many cases, vegetables may either get rotted or the market gets full due to imbalance in supply, price and demand. The waste vegetables and wild plants contain electrochemically active compounds, which can be used for preparation of rechargeable bio-battery cells. In this study, a set of battery cells was constructed by coupling the electroactive compounds of Onion-Radish, Onion-Bitter Orange, Onion-Cactus, Turnip-Radish, Turnip-bitter orange and Turnip-cactus. The fresh and boiled juices of these vegetables and wild plant combinations were used and the reaction conditions were optimized to maximize the output voltage. The output voltage was measured before and after charging of cells for different charging times, juice volume, charging voltage and pH of cell media. The effect of media was explored by changing the media nature from acidic to neutral and neutral to basic. It was observed that the voltage of most of the cells in basic media is higher than the neutral and basic media. Among the investigated batteries, turnip-cactus single cell battery produced an open circuit voltage of 2.13 V while the onion-radish battery produced an open circuit voltage 1.9 V.

Posted on: December 2021

Authored: Shaharin Anwar Sulaiman

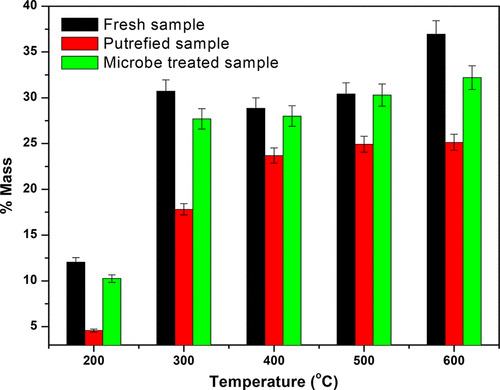

In this study, water hyacinth was converted into highly flammable bio-oil through a two-step catalytic pyrolysis approach. A three-pronged approach, based on biochemical pretreatment of the biomass, use of clinkered catalyst, and an additional pyrolysis step, was adopted to produce highly upgraded bio-oils. Fresh, putrefied, and microbe treated water hyacinth was pyrolyzed into oil, gas, and solid residue. The oil product of the first step of pyrolysis contained 9.42%, 36.72%, and 30.38% of combustible liquids by mass, respectively. The fractional distillation of the oil product of fresh, putrefied, and microbe treated samples resulted in 11.56%, 7.1%, and 31.67% of residue by mass, respectively. These residues were repyrolyzed, and the oil and gas products of the first and second step of the pyrolysis were further analyzed for their chemical composition. After two-stage pyrolysis, the amount of the highly upgraded oil was increased to 34.34%, 58.31%, and 43.21% by mass, respectively. The bio-oils, obtained from fresh, putrefied, and microbe treated-samples, were significantly different in terms of their chemical nature and the number of compounds.

Posted on: October 2017

Authored: Shaharin Anwar Sulaiman