Cement catalyzed conversion of biomass into upgraded bio-oil through microwave metal interaction pyrolysis in aluminum coil reactor

Author: Shaharin Anwar Sulaiman - January 2018

Abstract

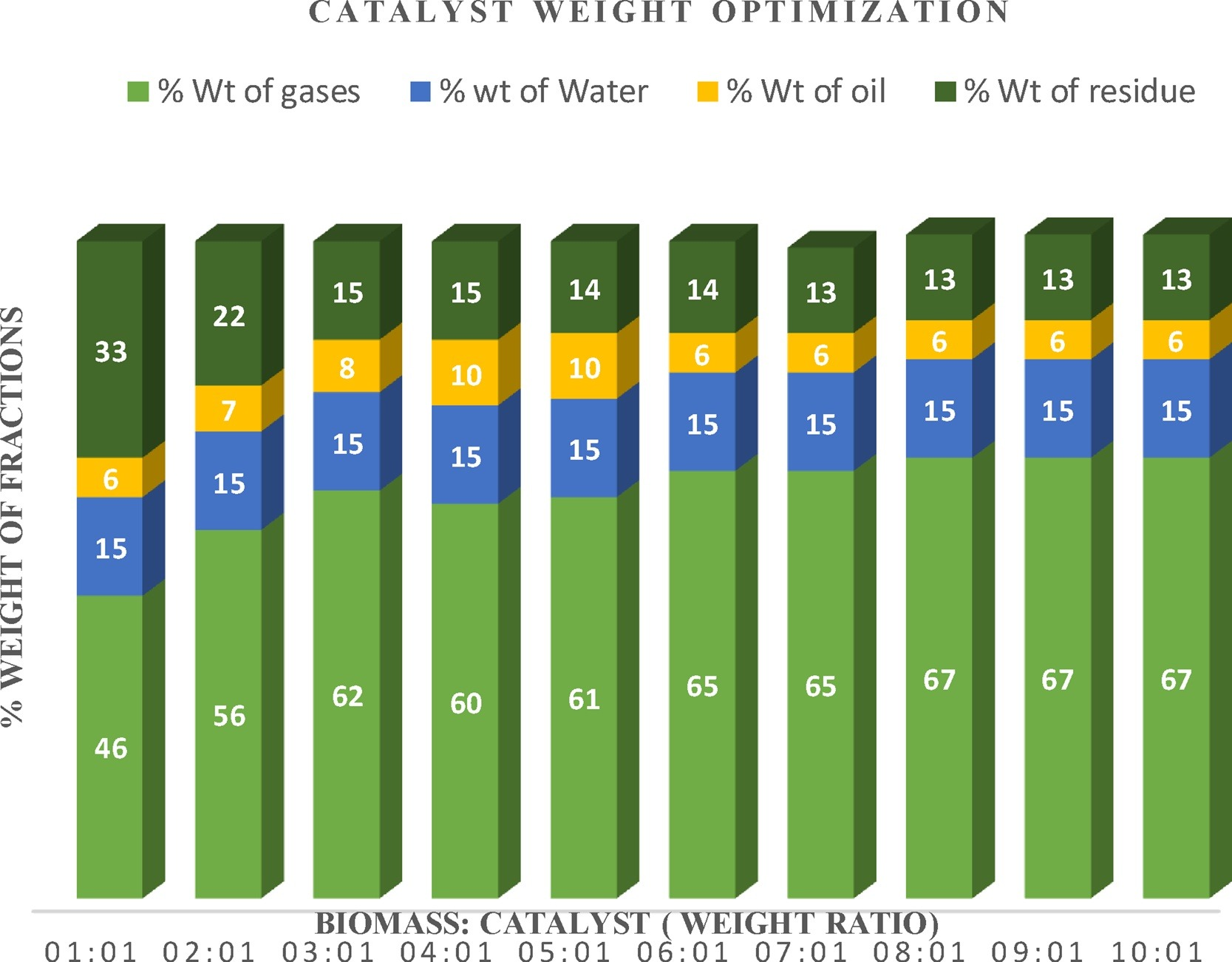

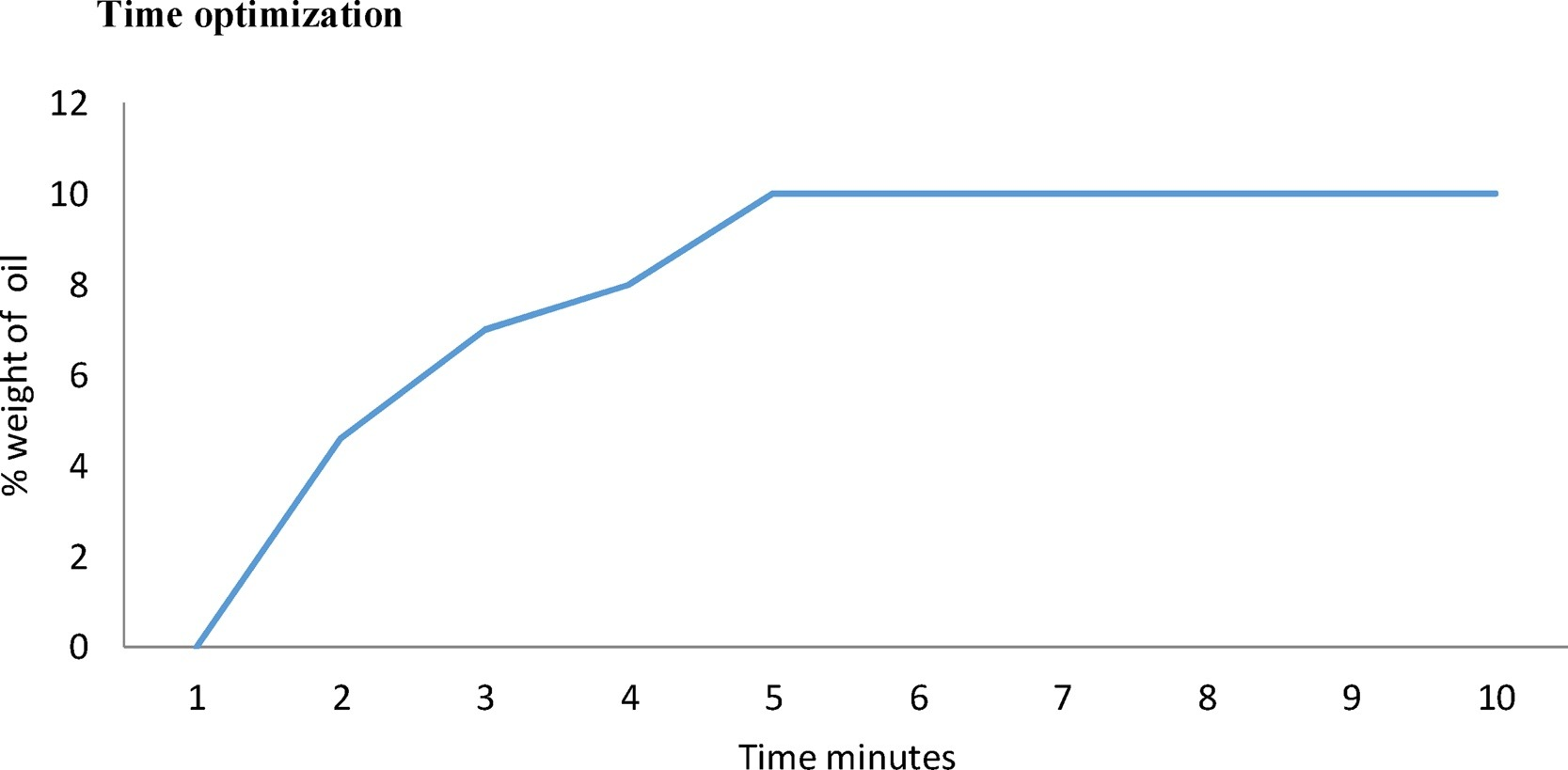

Metal objects spark in the microwaves, exposing metals to melting point temperatures. The resulting heat can be utilized for the pyrolysis of biomass into upgraded bio oil. In this work pyrolysis was carried out both in the presence and absence of catalyst and the upgradation of bio oil was found the combine action of microwave heating, microwave effects and the catalytic activity of cement. Catalytic pyrolysis of biomass was carried out by mixing powdered biomass with fine powder of cement and placing the resulting mixture in an aluminum coil located in the baked clay reactor followed by its exposure to the microwaves. In this process aluminum coil was used as microwave receiving and heat generating antenna. All these experiments were carried out in a modified domestic microwave oven. The amount of product fractions like bio-oil, biogas and biochar was determined in terms of the mass of catalyst, time of reaction and the gauge of aluminum wire used for the preparation of coil. The bio oil obtained under the optimum conditions was analyzed using Gas chromatography mass spectrometry and the gaseous product was analyzed using chemical tests. Significant difference was observed in the chemical composition of bio oils prepared by catalytic and non-catalytic processes. Further, the oxygen contents of both types of the bio oil were found less than those to be obtained by conventional pyrolysis.

Methodology

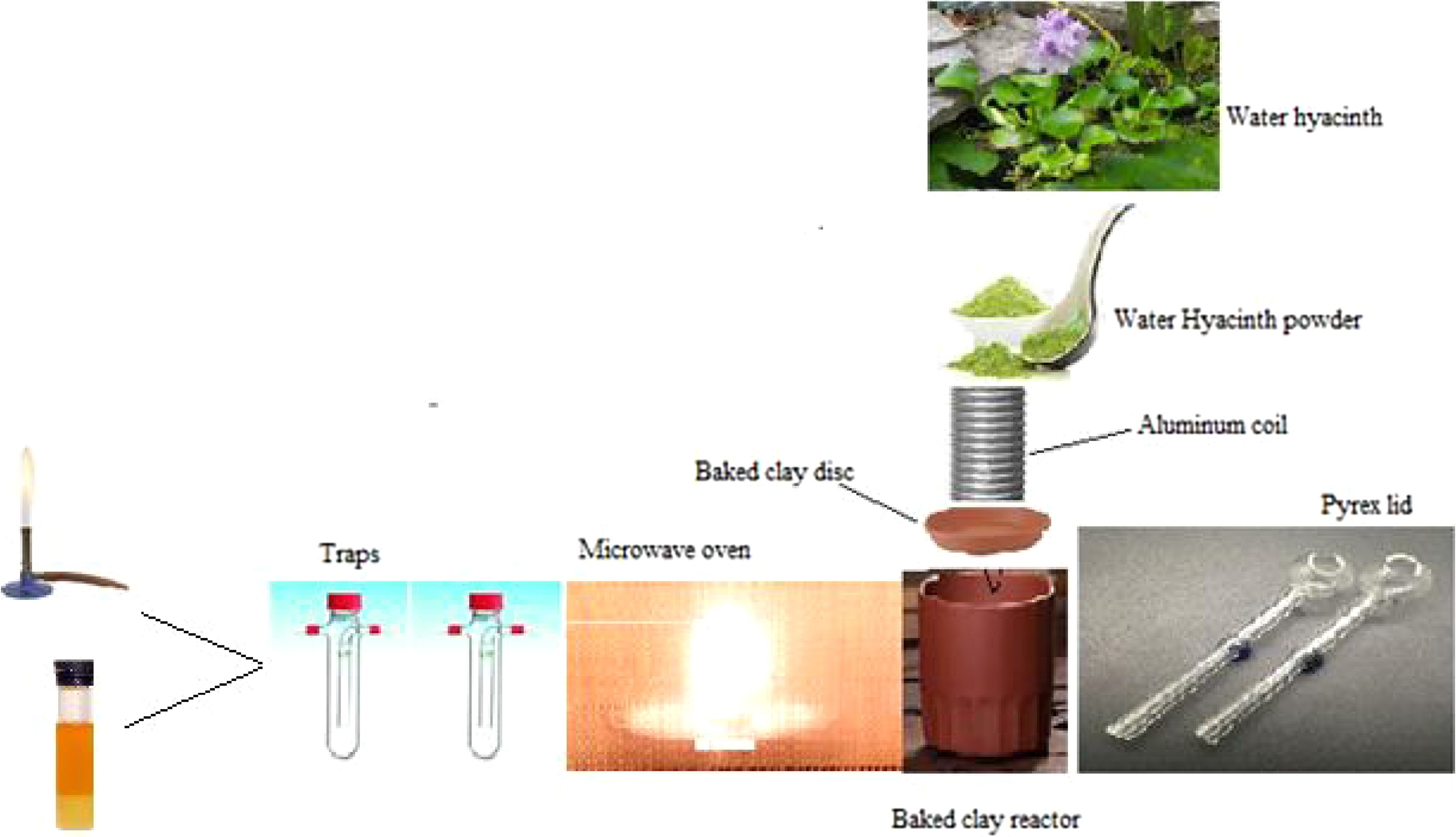

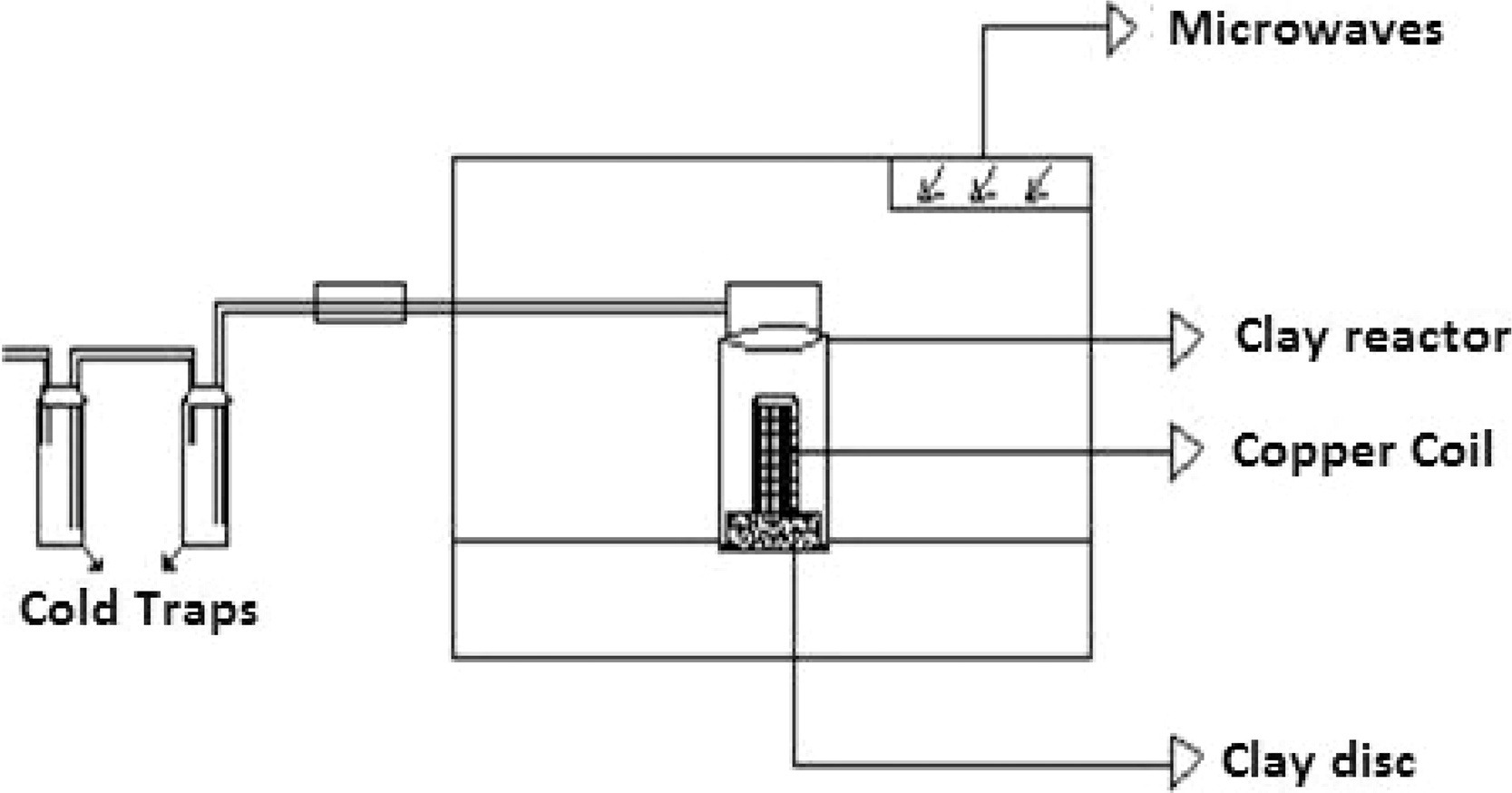

In this work biomass was pyrolyzed into highly upgraded bio oil both in the presence and absence of catalyst. Cement catalyzed reactions were carried out by mixing fine powder of the biomass with cement as catalyst. This mixture was loaded inside the aluminum coil which was placed in the baked clay reactor. This was followed by closing the reactor with Pyrex lid having side tube. It was the Teflon tap which ensured leak proof closure of baked clay reactor by the Pyrex lid. This loaded and closed reactor was placed inside the microwave oven and connected to the cold traps and chemical traps through the window made in the side wall of microwave oven. Just like our previous work, microwaves were applied in pulses of two minutes to avoid damage of baked clay reactor by overheating. Violence of reaction and brighter sparks were observed in the first 2-3 min after exposure to microwaves. The vapours and gases produced inside the reactor replaced all the entrapped air resulting an inert atmosphere for this reaction.

Impact & Benefits

Resource Utilization: Biomass is a renewable resource, and converting it into bio-oil through pyrolysis offers a way to utilize organic waste materials, agricultural residues, or dedicated energy crops effectively. This reduces dependence on fossil fuels and contributes to sustainable resource management.

Biofuel Production: Bio-oil obtained from biomass pyrolysis can serve as a precursor for various biofuels, such as biodiesel or bio-jet fuel. These biofuels have lower carbon footprints compared to traditional fossil fuels, potentially reducing greenhouse gas emissions and mitigating climate change.

Microwave-Assisted Pyrolysis: Using microwave technology can enhance the efficiency of the pyrolysis process by rapidly heating the biomass, leading to faster reaction rates and potentially higher yields of bio-oil. This can improve the overall economics of biofuel production and reduce energy consumption compared to conventional heating methods.

Aluminium Coil Reactor: The use of an aluminum coil reactor offers advantages such as high thermal conductivity and resistance to corrosion. Aluminum is also lightweight, making the reactor easier to handle and potentially reducing manufacturing costs compared to reactors made from other materials.

Market Potential

Technological Readiness: The technology needs to be at a sufficient level of development and scalability to be commercially viable. If it's still in the research or early development stage, further investment in R&D may be required to optimize the process, improve efficiency, and reduce costs.

Economic Viability: The cost of producing bio-oil via this method needs to be competitive with alternative fuels and conventional petroleum-based products. Factors such as biomass feedstock availability and cost, reactor construction and operation costs, energy efficiency, and product yield will influence the economic viability of the process.

Regulatory Environment: Government policies and regulations play a significant role in shaping the market potential for biofuels. Incentives such as subsidies, tax credits, renewable fuel mandates, and carbon pricing can incentivize the production and use of biofuels. Additionally, regulations related to fuel quality, emissions standards, and sustainability criteria may impact market access and competitiveness.

Market Demand: The demand for renewable fuels, including biofuels, is influenced by factors such as energy security concerns, environmental regulations, corporate sustainability goals, and consumer preferences for cleaner and greener alternatives. Understanding market dynamics and identifying niche markets where bio-oil can offer unique advantages will be crucial for commercialization.