Research Success Stories

An innovative intumescent fire retardant paint keeps flames and fumes at bay for up to two hours THE phrase "spreading like wildfire" should not be taken lightly in case of a real fire. As soon as an ignition source is flared in the proximity of fuel and oxygen, not only does a fire begin, but it will spread very dramatically and rapidly too, moving from a mere flickering spark into a blazing disaster in a matter of minutes. Fires spread in the way heat travels, through direct contact between materials and via electromagnetic waves reaching an object which absorbs it before combusting. As in many recent Malaysian fire tragedies claiming lives and destroying properties, many factors lead to uncontrollable blazes. From construction materials to on-site stores and walls or doors, the lack of fire protection for all these, can lead to fire spreading faster. However, if these walls and doors can withstand the intense heat and instant damage from a fire, there may be a chance to put out the flames and save lives and structures.

Posted on: January 2017

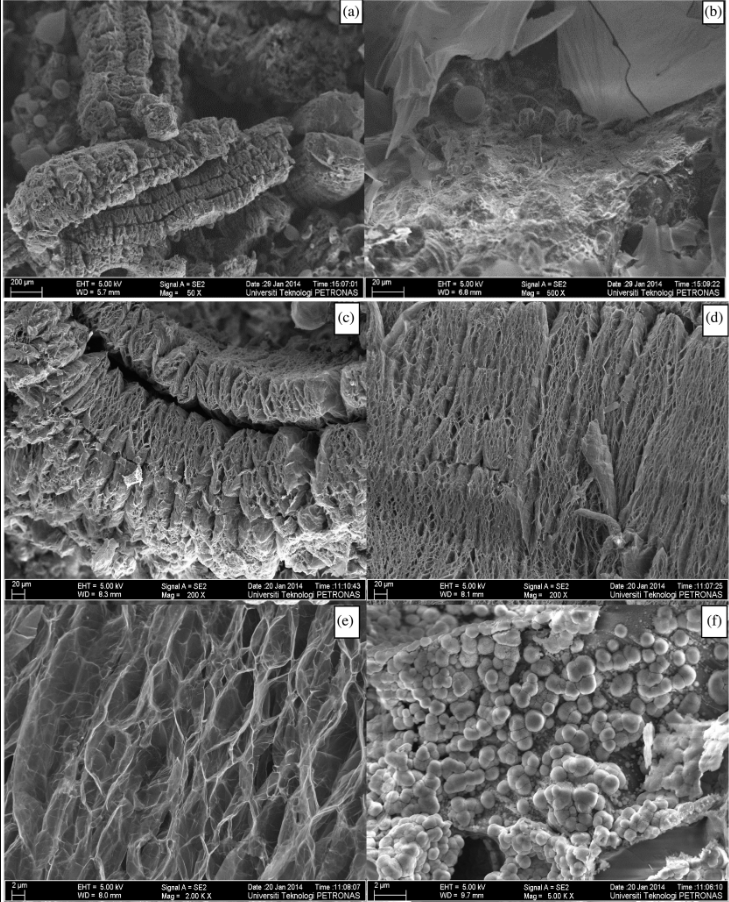

Authored: Faiz Ahmad

This study presents the results of intumescent fire retardant coatings (IFRCs) developed to investigate the synergistic effects of mineral fillers (clay and wollastonite) based IFRC towards heat shielding, char expansion, morphology, composition, gaseous products and residual weight. The fire test has been performed to study the heat shielding effect of IFRCs on the substrate using UL-1709 standards. The results showed the synergistic effect of clay and wollastonite using 5 wt.% enhanced the fire protection, performance with recorded substrate temperature 113 °C after 1-h fire test. Field Emission Scanning Electron Microscopy (FESEM) and High-Resolution Transmission Electron Microscopy (HRTEM) showed the micrograph of compact char structure that increased char integrity due to the presence of inorganic fillers. X-ray Diffraction (XRD) and Fourier Transform Infrared Spectroscopy (FTIR) results showed the presence of boron phosphate, silicon phosphate oxide, aluminum borate in char that improved the thermal performance of IFRC up to 800 °C. X-Ray Photoelectron Spectroscopy (XPS) confirmed that 5 wt% (IFRC-5) of clay and wollastonite increased the carbon content up to 50.67%, lowering oxygen content to 27.73% in the char that enriched the fire resistance performance of the coating. Pyrolysis-Gas Chromatography-Mass Spectrometry (Pyrolysis GC-MS) confirmed that formulations IFRC-5 released less gaseous product concentration compared to IFRC-C and maximum reduction in gases was recorded from 3.4e+07 to 1.08e+07. Thermogravimetric analysis (TGA) demonstrated in residual weight was increased to 46.45% for IFRC-5 which resulted in the high thermal stability of the coating.

Posted on: April 2018

Authored: Faiz Ahmad

With advancements in the automated industry, electromagnetic inferences (EMI) have been increasing over time, causing major distress among the end-users and affecting electronic appliances. The issue is not new and major work has been done, but unfortunately, the issue has not been fully eliminated. Therefore, this review intends to evaluate the previous carried-out studies on electromagnetic shielding materials with the combination of Graphene@Iron, Graphene@Polymer, Iron@Polymer and Graphene@Iron@Polymer composites in X-band frequency range and above to deal with EMI. VOSviewer was also used to perform the keyword analysis which shows how the studies are interconnected. Based on the carried-out review it was observed that the most preferable materials to deal with EMI are polymer-based composites which showed remarkable results. It is because the polymers are flexible and provide better bonding with other materials. Polydimethylsiloxane (PDMS), polyaniline (PANI), polymethyl methacrylate (PMMA) and polyvinylidene fluoride (PVDF) are effective in the X-band frequency range, and PDMS, epoxy, PVDF and PANI provide good shielding effectiveness above the X-band frequency range. However, still, many new combinations need to be examined as mostly the shielding effectiveness was achieved within the X-band frequency range where much work is required in the higher frequency range.

Posted on: 2013

Authored: Faiz Ahmad

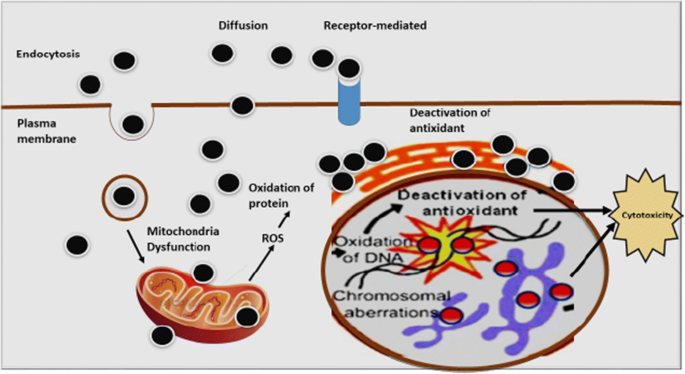

Targeting the small intestine employing nanotechnology has proved to be a more effective way for site-specific drug delivery. The drug targeting to the small intestine can be achieved via nanoparticles for its optimum bioavailability within the systemic circulation. The small intestine is a remarkable candidate for localized drug delivery. The intestine has its unique properties. It has a less harsh environment than the stomach, provides comparatively more retention time, and possesses a greater surface area than other parts of the gastrointestinal tract. This review focuses on elaborating the intestinal barriers and approaches to overcome these barriers for internalizing nanoparticles and adopting different cellular trafficking pathways. We have discussed various factors that contribute to nanocarriers' cellular uptake, including their surface chemistry, surface morphology, and functionalization of nanoparticles. Furthermore, the fate of nanoparticles after their uptake at cellular and subcellular levels is also briefly explained. Finally, we have delineated the strategies that are adopted to determine the cytotoxicity of nanoparticles.

Posted on: 2013

Authored: Faiz Ahmad

Zirconium phosphate (ZrP) recently introduced in intumescent fire protective coating has shown improvement in developing ceramic layer. The tubular halloysite clay (THC) due to its unique molecular structure can be combined with ZrP to enhance fire resistance by developing a strong silica network on the char surface. This study is aimed to investigate the synergistic effects of tubular halloysite clay and zirconium phosphate fillers to improve the thermal performance of the intumescent coating. The control coating formulation and a range of coating formulations using a combination of weight percentage of THC and ZrP were developed to study the influences of fillers on fire performance. The char expansion and fire resistance tests of the coatings were conducted using furnace fire test and Lab scale fire jet. Thermal stability of the coating was determined by TGA and char was characterized by FESEM, XRD, FTIR and XPS. Water-resistance test of the coating was performed according to ASTM D-870. Results showed that the reinforcement of THC-ZrP showed promising improvement on the performance of IFC and substrate temperature was far below the critical temperature, 550 °C. Sample HZ 5 showed the least backside steel substrate temperature of 219 °C. Expansion rate of char was found reduced with the addition of THC but improved the char compactness. The addition of THC and ZrP in IFC improved 18% fire resistance performance and 5% residual wt. Of char. Char morphology showed silica network, XRD and FTIR confirmed the presence of silicon. Water absorption test showed 95% less water absorption (HZ-5) compared to control coating. Post water immersion, fire test showed 7% increase in substrate temperature which is 18% less than control coating after water immersion fire test.

Posted on: June 2022

Authored: Faiz Ahmad