Research Success Stories

The thermal properties of residual char of basalt fiber (BF) reinforced intumescent coating (IC) obtained after high temperature burning were studied. Seven intumescent coating formulations were prepared in which the weight percentage of basalt is varied from 0 to 3 wt.% of the total formulation. The effects of BF weight percentage on fire resistance of IC, and char morphology and composition were also studied. The heat barrier effect was analyzed by using a Bunsen burner (ASTM E119). Field emission scanning electron microscopy (FESEM), thermogravimetric analysis (TGA), and X-ray photoelectron spectroscopy (XPS) were used to investigate the IC and residual chars. Furthermore, the thermal conductivity was calculated as a function of temperature to compare the structure and properties of char residues. Intumescent chars with different weight percentages of BFs (in particular formation of pores of different sizes) were firstly verified. The interpretations were not in agreement with the thermal conductivity data. IC-B3 is the formulation that contains 3 wt.% of BF had thermal conductivity value of 0.114 Wm-1 K-1. The morphological study confirmed that 3 wt.% of BF formed a network that protected the underlying steel substrate from temperature rise in the event of fire. TGA results showed that BF reinforced formulations; IC-B3 had 36.26% of residual weight at 800 °C as compared to IC-B0, which had 27 wt.%. Elemental analysis showed that IC-B3 had enhanced carbon content of 63.1% in the residual char. Pyrolysis-gas chromatography-mass spectrometry (Pyrolysis-GCMS) revealed that IC-B3 suppressed the release of toxic gases as compared to IC-B0 and the average percentage of released gases decreased from 83.3%-57.1%.

Posted on: July 2019

Authored: Faiz Ahmad

The current research discusses the development of poly (lactic acid) (PLA) and poly-(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) reinforced nanocrystalline cellulose bionanocomposites. The nanocrystalline cellulose was derived from waste oil palm empty fruit bunch fiber by acid hydrolysis process. The resulting nanocrystalline cellulose suspension was then surface functionalized by TEMPO-mediated oxidation and solvent exchange process. Furthermore, the PLA/PHBV/nanocrystalline cellulose bionanocomposites were produced by solvent casting method. The effect of the addition of nanocrystalline cellulose on structural, morphology, mechanical and barrier properties of bionanocomposites was investigated. The results revealed that the developed bionanocomposites showed improved mechanical properties and decrease in oxygen permeability rate. Therefore, the developed bio-based composite incorporated with an optimal composition of nanocrystalline cellulose exhibits properties as compared to the polymer blend.

Posted on: February 2017

Authored: Faiz Ahmad

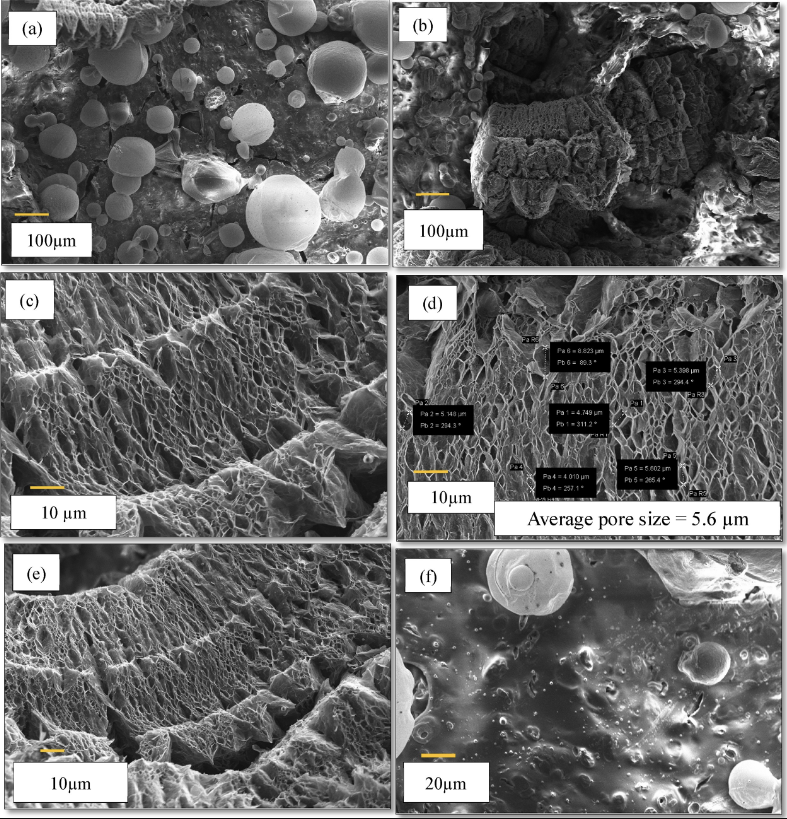

This work aims at evaluating the potential of nano-sized zinc borate as substitution of boric acid for thermal degradation and gaseous products in expandable graphite based intumescent fire retardant coating IFRC systems. The thermal degradation and pyrolysis of intumescent flame retardant coatings was characterized by bunsen burner fire test, thermogravimetric analysis (TGA), field emission scanning electron microscopy (FESEM), energy dispersive spectrometry (EDX), X-ray diffraction (XRD), fourier transformed infra-red analysis (FTIR), X-ray photoelectron spectroscopy (XPS) and gaseous emission analysis (Py-GC). Bunsen burner fire test reveals that the partial substitution of zinc borate (6.61 mass%) imparts a substantial improvement in thermal stability and reduces steel substrate temperature to 124 °C. From thermogravimetric analysis results, it was shown that this composition increases char residual mass from 39 to 46.14 mass%. The morphological structures of char residue were investigated by FESEM and it indicates that zinc borate promotes more continuous and compact char layers that hinder the heat diffusion and oxygen transmission effectively. XRD and FTIR results show that zinc borate develops a zinc-based glassy intumescent shield i.e. zinc bis (hydroxyanthrapyrimidine) dehydrate (C30H14N4O4Zn.2H2O) that strengthens the char. The new chemical species enhances the thermal stability of the freshly formed char at high temperature and provides an enhanced fire protection. XPS analysis shows the higher carbon contents in formulation IF-5 (6.6 mass%) and endorses high char residue. The Py-GC analysis confirms release of less toxic gaseous products in IF-5 formulation, considering their type and concentration, as compared to control formulation, and is considered as an environmentally safe intumescent formulation.

Posted on: October 2018

Authored: Faiz Ahmad

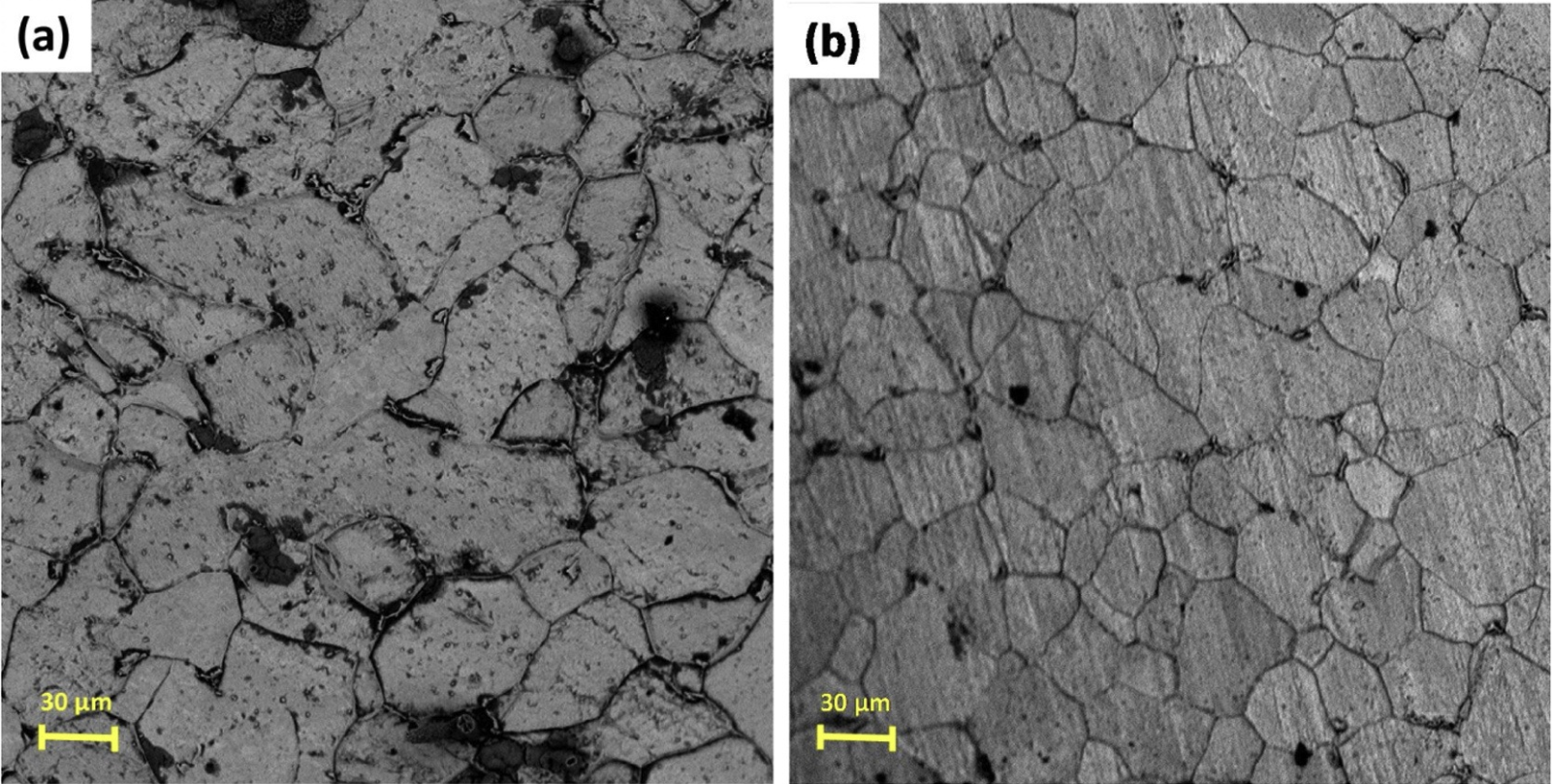

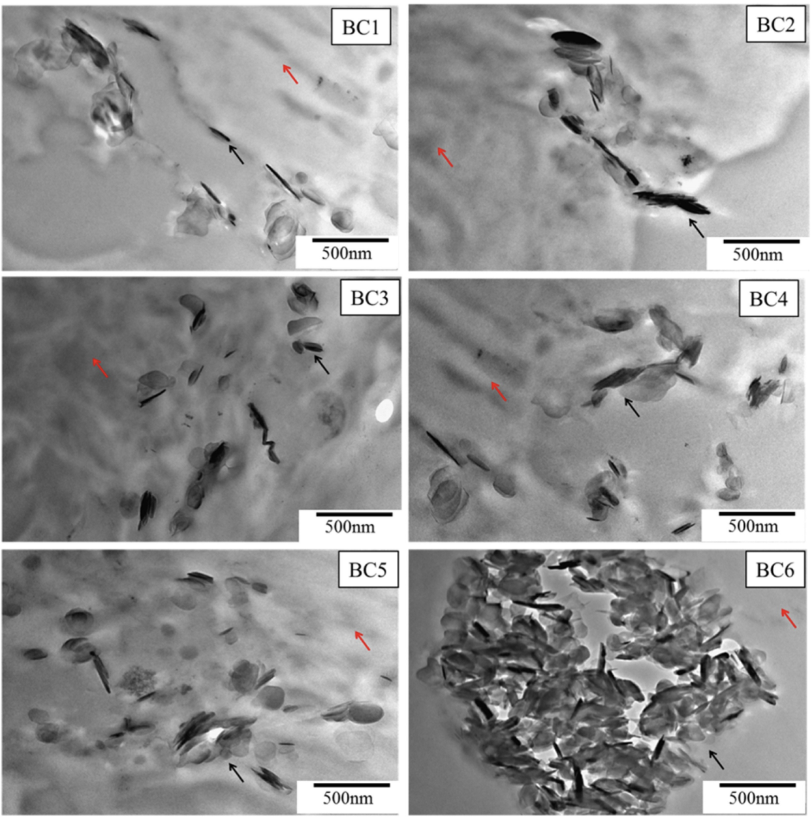

Heat dissipation remains a key challenge to be addressed, determining the performance and durability of smart electronic devices. Graphene reinforced metal matrix composites have been extensively studied as a thermal management material due to their high thermal conductivity and low coefficient of thermal expansion. The emphasis of this review is pivoted on the thermal conductivity enhancement of graphene reinforced Cu matrix composites developed in the recent literature. An overview of factors affecting thermal conductivity of composite namely defect processing route, density, graphene derivative, lateral size, concentration, alignment, graphene/matrix interfacial bonding and graphene modification are discussed. An extensive weightage is given to the processing route as it is the most influential factor in determining the enhancement efficiency. Furthermore, graphene based functional products such as heat spreader and heat sink developed for heat dissipation of electronic devices are also reviewed. Finally, the development and outlook for graphene based Cu composites are presented.

Posted on: May 2021

Authored: Faiz Ahmad

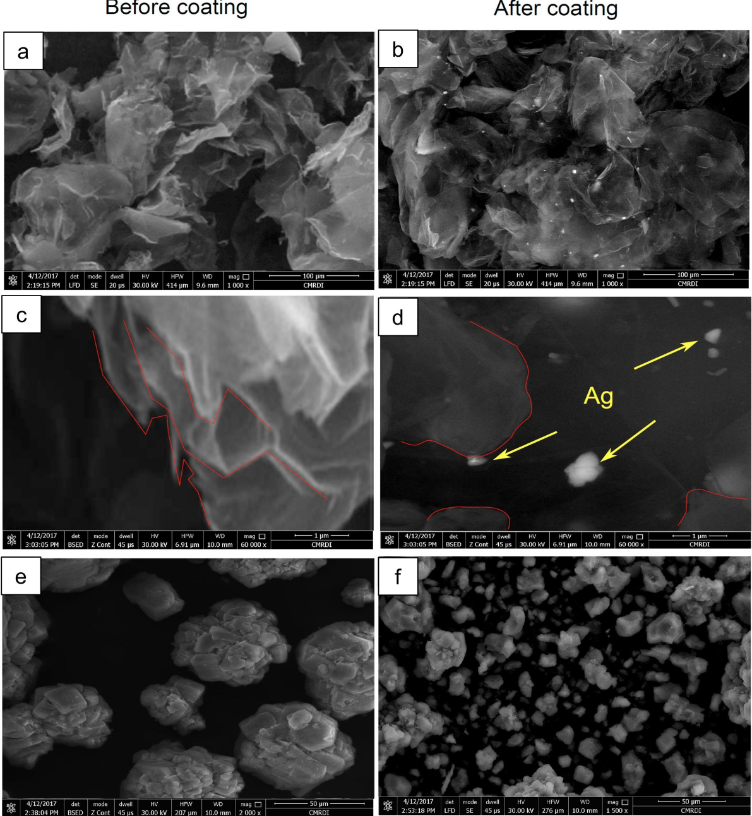

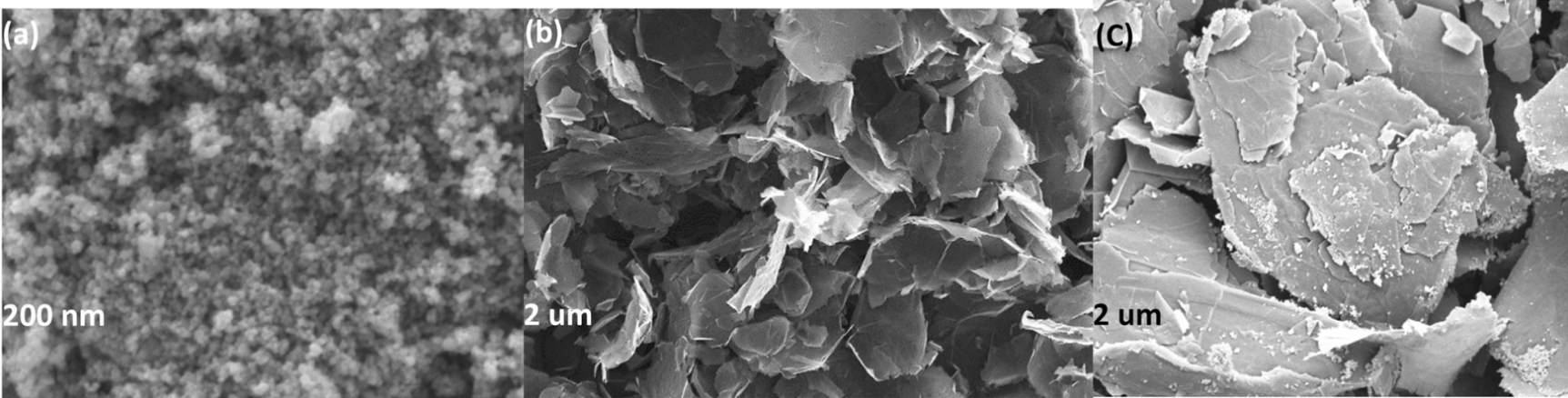

Nowadays, the demand for microwave absorption materials (MAMs) is intensifying in response to the rising sensitivity of electromagnetic pollution and the need for contemporary military security. Therefore it is crucial to develop outstanding performance MAMs. In this study, magnetite-modified graphene (MMG) was synthesized using the solvothermal method by varying the amount of magnetite with graphene nanoplatelets. Later, to optimize the best-suited proportion at which maximum microwave absorption properties were achieved. The structural morphology, phase crystallinity, and chemical composition of the MMG composites were investigated. The morphology reveals that magnetite particles are firmly attached to the edges of the graphene nanoplatelets (GNP). For the microwave absorption investigation, the permittivity, permeability, and reflection loss values of the composite absorbers were measured with a vector network analyzer. The reflection loss of the MMG with a low filler proportion reaches -56.64 dB at a frequency 11.7 GHz and bandwidth 2.16 GHz at a thickness of 3 mm. The sample (3-7) was most suitable for good microwave absorption properties.

Posted on: March 2023

Authored: Faiz Ahmad