Research Success Stories

This research work presents the enhancement of thermal performance of intumescent fire-retardant coatings (IFRCs) to investigate the synergistic effects of novel type of fiber reinforcement (basalt fibers) towards heat shielding capability for steel structures. The coating basis consists of bisphenol-A epoxy resin (NPEL-128) cross-linked with polyamide amine (ACR Hardener (H-2310)), mixed with expandable graphite (EG), ammonium polyphosphate (APP), melamine and boric acid. Various formulations with different fiber loading were synthesized and characterized. Bunsen burner test in accordance to UL-1709 was performed to examine their fire retardant properties. Moreover, furnace test was carried out to investigate the char expansion. The results showed that 2 wt% basalt fibers (IFRC-B2) greatly enhanced the heat insulation performance, the steel plate backside temperature reaching 187°C after 1-h fire test compared to 375°C for the control formulation (CF) without fiber reinforcement. Char expansion measurements carried out after furnace test show that in the presence of basalt fibers the expansion of IFRC-B2 was twice that of CF. Char was also analyzed by Field Emission Scanning Electron Microscopy (FESEM). Micrographs revealed deep cracks on CF char surface, allowing the heat to diffuse more rapidly and explained the poor fire performances. The char of IFRC-B2 was smooth and dense, while distribution of basalt fibers and char cells were homogenous, with presence of small voids of about similar size, which limited heat transfers. Thermogravimetric analyses (TGA) in pyrolysis conditions showed that residual weight increases by 10 wt%, confirming the increase in thermal stability of the basalt containing formulation.

Posted on: 2019

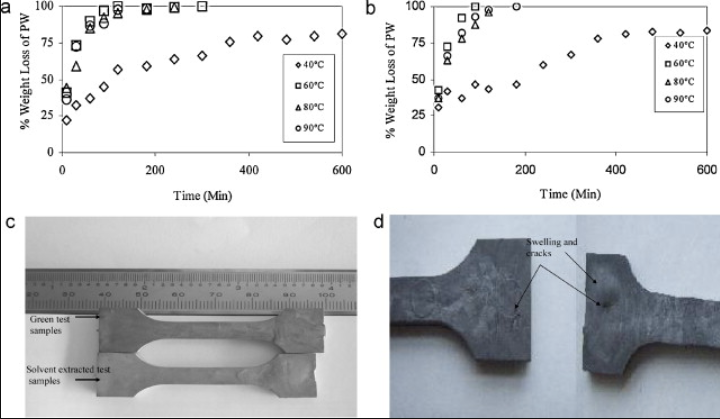

Authored: Faiz Ahmad

This study presents the results of corrosion behavior of powder injection molded 316L stainless steel parts sintered in vacuum. The feedstocks of metal powder and plastic binder were prepared and their viscosity was measured. Green samples were injection molded and binder was removed from the green parts. Brown test parts were sintered at 1325 °C with heating rate of 5 °C/min and 10 °C/min for 2 h followed by the same cooling rate. Corrosion response of the sintered test samples was measured by weight loss method in Ringer's Solution of pH 7.4 for 15 days. The test samples using cooling rate 10 °C/min showed higher mechanical properties and improved corrosion resistance compared to those sintered at low heating and cooling rate. High cooling rate reduced the evaporation of Cr and developed passive chromium oxide layer on the test samples resulting improved corrosion resistance.

Posted on: January 2012

Authored:Faiz Ahmad

The aim of this study was to characterize the adhesion bonding of intumescent coating and the primer on steel substrate with respect to its mechanical, physical and chemical properties, before and after a fire test. The coated steel substrates were subjected to fire in a furnace at 950 °C for various durations ranging from 30, 45, and 90 to 120 min. The coatings were characterized by Thermogravimetric Analysis (TGA) while the char from fire test was characterized by Scanning Electron Microscopy (SEM), Fourier Transform Infrared Spectroscopy (FTIR). For mechanical properties, the shear strength of the intumescent coating was measured for various coating thicknesses ranging from 1, 2, 3, 4, 10 to 22 mm through lap shear test. The changes in the adhesion bonding of the coatings, primer, and char with steel substrate microstructure were monitored using SEM. The microstructure observation indicated a profound mechanical interlocking mechanism between the primer coating and the steel substrate. Despite the two-hour fire test, the temperature of the steel substrate remained below 100 °C and no re-crystallization was observed. A considerable decrease in shear strength of the intumescent coating, primer and steel substrate from 1.95 MPa to 0.23 MPa was also measured as the thickness of the coating substrate was increased from 1 mm to 22 mm, respectively.

Posted on: February 2019

Authored:Faiz Ahmad