The study of adhesion between steel substrate, primer, and char of intumescent fire retardant coating

Author: Faiz Ahmad - February 2019

W.C. Puspitasari, Sami Ullah, Patthi Hussain, Puteri S.M. Megat-Yusoff, Patrick J. Masset

Abstract

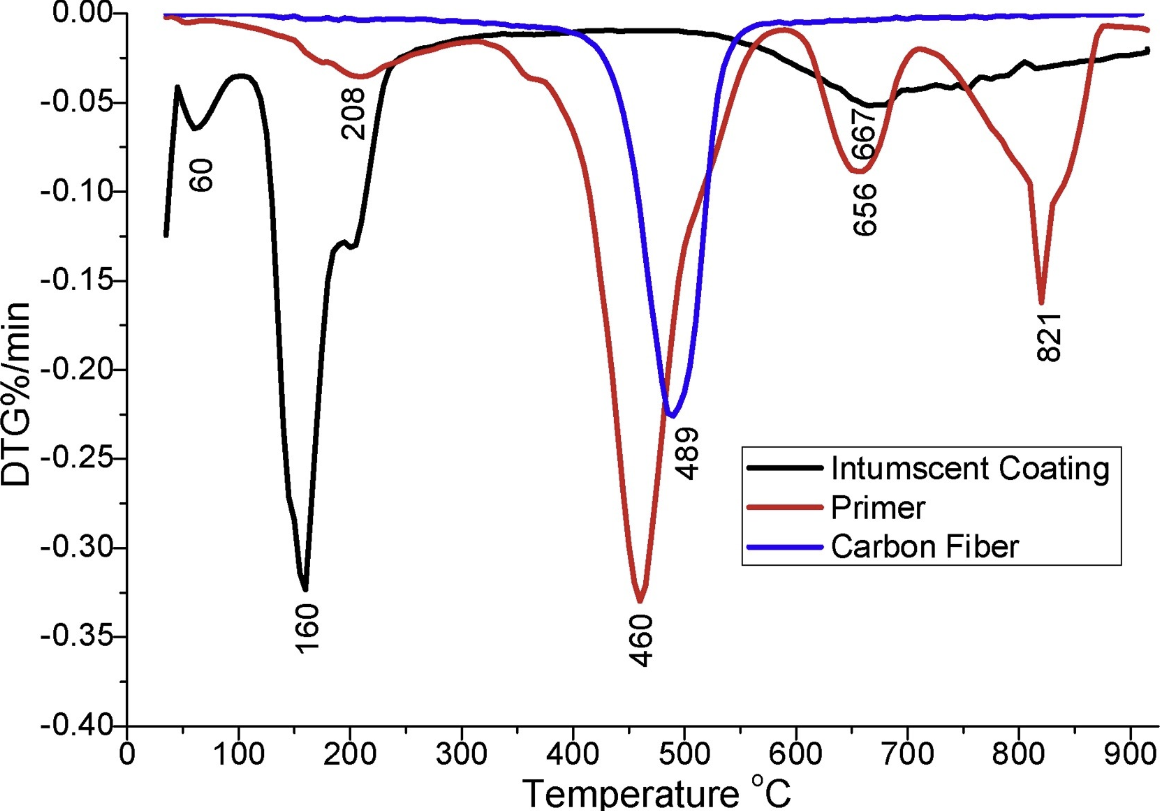

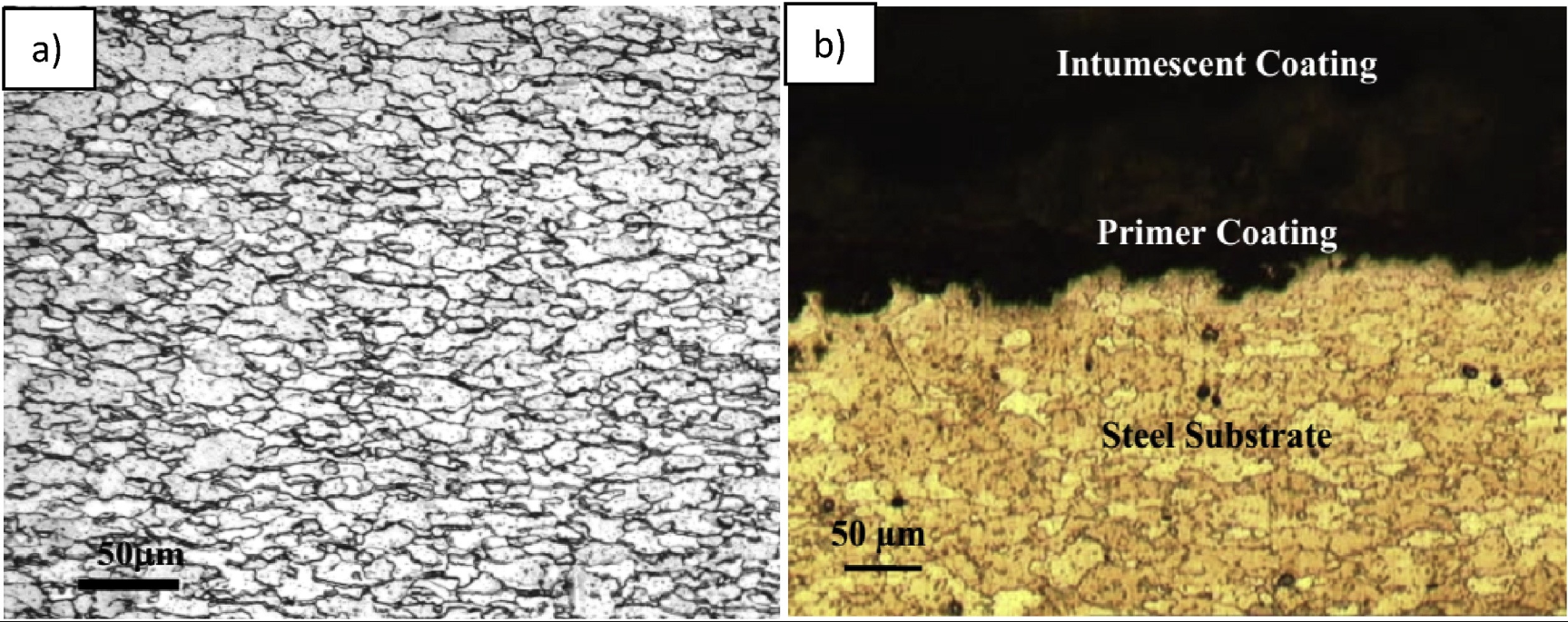

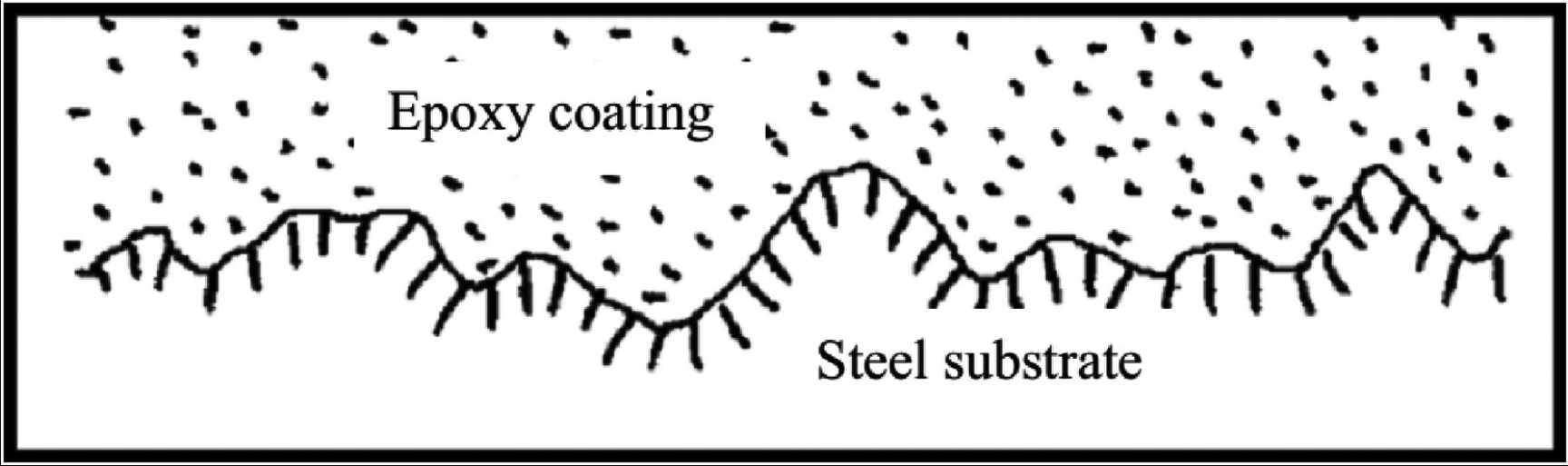

The aim of this study was to characterize the adhesion bonding of intumescent coating and the primer on steel substrate with respect to its mechanical, physical and chemical properties, before and after a fire test. The coated steel substrates were subjected to fire in a furnace at 950 °C for various durations ranging from 30, 45, and 90 to 120 min. The coatings were characterized by Thermogravimetric Analysis (TGA) while the char from fire test was characterized by Scanning Electron Microscopy (SEM), Fourier Transform Infrared Spectroscopy (FTIR). For mechanical properties, the shear strength of the intumescent coating was measured for various coating thicknesses ranging from 1, 2, 3, 4, 10 to 22 mm through lap shear test. The changes in the adhesion bonding of the coatings, primer, and char with steel substrate microstructure were monitored using SEM. The microstructure observation indicated a profound mechanical interlocking mechanism between the primer coating and the steel substrate. Despite the two-hour fire test, the temperature of the steel substrate remained below 100 °C and no re-crystallization was observed. A considerable decrease in shear strength of the intumescent coating, primer and steel substrate from 1.95 MPa to 0.23 MPa was also measured as the thickness of the coating substrate was increased from 1 mm to 22 mm, respectively.

Methodology

Commercially available Chartek 7 intumescent coating and the intergard 251 primer coating were supplied by the International Paint Sdn. Bhd. Pasir Gudang, Johor AkzoNobel Malaysia. The coating was reinforced epoxy intumescent fireproofing coating, suitable for the protection of steel in hydrocarbon (pool and jet) fires. Primer coating Intergard 251 is one of the preferred primer coatings which completed the primer qualification procedure from International Coatings. Intergard 251 is a zinc phosphate based primer coating, resulting in a two-component epoxy anti-corrosive primer pigmented with zinc phosphate.

Impact & Benefits

Enhanced Safety: Intumescent coatings help maintain the structural integrity of steel during fires, preventing collapse and allowing safe evacuation.

Temperature Reduction: Intumescent coatings significantly reduce the temperature of the steel substrate during a fire, preventing it from reaching critical failure points (e.g., 550°Cfor load-bearing collapse).

Stable Adhesion: Ensuring stable adhesion between the intumescent coating and steel substrate is crucial to maintaining the protective qualities of the coating under fire conditions.

Surface Preparation: Proper surface treatment and use of primers are essential for enhancing adhesion and preventing corrosion.

Public Safety: Enhances the safety of occupants by providing more time for evacuation and reducing the risk of structural collapse during fires.

Asset Protection: Minimizes damage to structural steel, reducing repair costs and extending the lifespan of buildings and structures.

Findings/Figures and Research Data

The intumescent coating had a good thermal barrier by showing temperature reduction up to 67.2 °C for up to two hours of fire test. The adhesion bonding between primer coating and steel substrate remained stable after 30, 45, 90 and 120 min furnace fire test. EDX analysis showed the high amount of silicon at 14.95 mass % in the char which might be helpful as Si-O-Si increased the adhesion bonding of intumescent coating and primer coating with the substrate. The maximum mass loss obtained was 60 wt. % at 470 °C-800 °C; at this stage, charring layer formation consumed approximately 60 mass % of the intumescent coating and gradually decreased by increasing the temperature. The FTIR analysis illustrated the strong characteristic vibration band Osingle bondH group, nitriles groups (Cdouble bondN), the stretching vibration peaks of the Psingle bondOsingle bondC band and the Pdouble bondO band, which implied that the fire retardant had a good system since the epoxy functional group remained stable after the fire test.

Market Potential

Construction and Infrastructure: High demand for fire-resistant materials in buildings, bridges, and infrastructure projects.

Regulatory Compliance: Need for coatings that meet stringent safety standards across different regions.

Safety and Durability: Market demand for products that provide reliable fire protection and structural integrity.

Technological Innovation: Opportunity for companies to invest in R&D and develop advanced coatings with improved adhesion properties.

Economic Benefits: Cost savings from reduced fire damage and lower maintenance needs.