Research Success Stories

This study evaluates the kinetic hydrate inhibition (KHI) performance of four quaternary ammonium hydroxides (QAH) on mixed CH4 + CO2 hydrate systems. The studied QAHs are; tetraethylammonium hydroxide (TEAOH), tetrabutylammonium hydroxide (TBAOH), tetramethylammonium hydroxide (TMAOH), and tetrapropylammonium hydroxide (TPrAOH). The test was performed in a high-pressure hydrate reactor at temperatures of 274.0 K and 277.0 K, and a concentration of 1 wt.% using the isochoric cooling method. The kinetics results suggest that all the QAHs potentially delayed mixed CH4 + CO2 hydrates formation due to their steric hindrance abilities. The presence of QAHs reduced hydrate formation risk than the conventional hydrate inhibitor, PVP, at higher subcooling conditions. The findings indicate that increasing QAHs alkyl chain lengths increase their kinetic hydrate inhibition efficacies due to better surface adsorption abilities. QAHs with longer chain lengths have lesser amounts of solute particles to prevent hydrate formation. The outcomes of this study contribute significantly to current efforts to control gas hydrate formation in offshore petroleum pipelines.

Posted on: January 2021

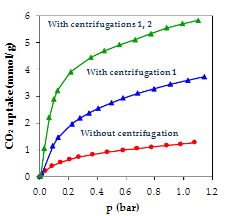

Authored: Azmi Shariff

Solvothermal synthesis is the most preferable preparation technique of metal-organic frameworks (MOFs) that consists of reactants mixing, ultrasonication, solvothermal reaction, product washing, and solvent evacuation. Owing to fast reaction kinetics in solvothermal reaction, this technique allows for production of uniform MOF particles with high crystallinity, high phase purity, and small particle sizes. However, it exhibits some difficulties of washing processes that may involve the blockage of pores due to incomplete removal of reactive medium from MOF products. The present study proposes an improvement of washing processes by introducing centrifugal separations with optimized parameters at two different stages: after reaction and after product washing. Nickel-based MOF-74 was synthesized as the experimental material for this purpose. The quality of the produced sample was evaluated by gas adsorption performance using CO2 at 1 bar and 25 Celcius. The final sample of the optimized synthesis routes was able to adsorb 5.80 mmol/g of CO2 uptake, which was competitive with literature data and significantly higher than the sample of the basic synthesis. Fourier-transform infrared spectroscopy (FTIR) and powder X-ray diffraction (PXRD) analysis revealed that the sample displayed much higher crystallinity structure and was clean from impurities after centrifugations. The outcome indicated the success of separation between MOF products and reactive medium during washing processes, leading to the effective pore activation of MOFs.

Posted on:June 2020

Authored: Azmi Shariff

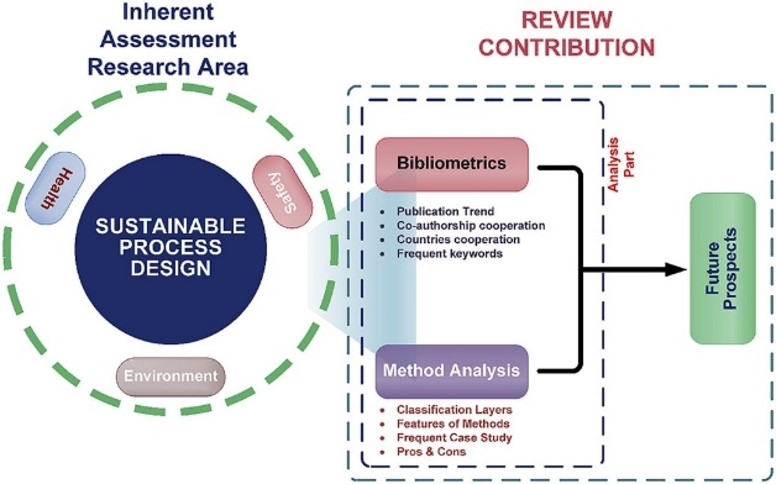

Chemical process manufacturing is associated with risks, which cannot be eliminated. Anyhow, controlling or minimizing of risks is possible up to a certain extent through various process safety strategies. Among these strategies, the inherent approach offers a sustainable process design. This review aims to offer an extensive survey regarding the bibliometrics and the features of the state-of-the-art inherent assessment methods. For the bibliometric part, numerous trends like publication trend, authors and geographical cooperation and prominent keywords are presented using the VOSviewer software. For the second intention, the scope and features of inherent assessments methods for sustainable process design are discussed in addition to the historical development of these methods. The techniques are categorized among seven groups based on the method adopted for inherent assessment along with the benefits and detriments of each group. It is revealed that initially, the inherent assessment has focused on the comparison of various process routes, whereas, the modern methods intend to minimize the risk. Furthermore, it is recognized that the process equipment approach is not much explored yet, which may improve the sustainable process designing via the equipment characteristics. Finally, the limitations of present schemes and future research directions for inherent assessment implications in the sustainable process design are also highlighted, such that the objectives of economic, healthier, safer and environmental-friendly process plants can be materialized.

Posted on: October 2019

Authored: Azmi Shariff

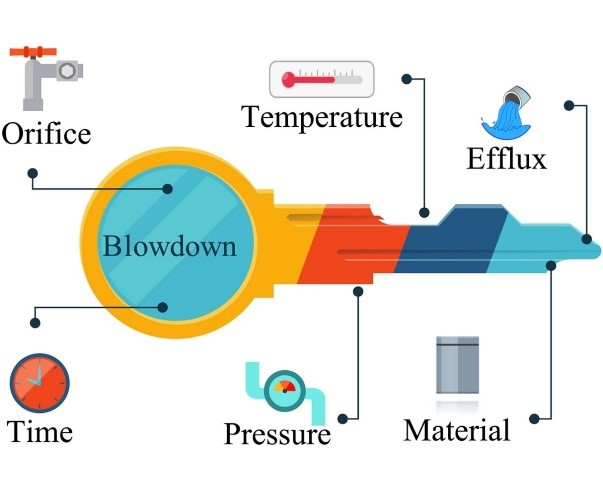

In process industry, failure or rupture of pressurized vessel is very dangerous especially when there is an escape of flammable gaseous mixture that can cause potential fire or explosion. One of the scenarios that causes such accidents is the blowdown process. Therefore, it becomes crucial to control blowdown process to prevent such accidents. It is important to design optimally to make sure that blowdown valve is according to the requirements. For the safe use of a pressure relief system, some of the parameters are critical, for example, selection of construction material, sizing of relief valves, temperature, and pressure, etc. There is no literature currently available that discusses all the mathematical models or simulation tools for optimum design of the blowdown process. This subject matters because the available models or tools cover different aspects of blowdown process. A meticulous review is required to present the applications of these models and tools based on the accidental scenarios. Therefore, this paper critically reviews the models and tools that are developed purposely to calculate optimum blowdown parameters based on fluid and vessel conditions. Recommendations are given for the development of new simulation tool to simulate phase change conditions especially when solid formation is involved.

Posted on: January 2020

Authored: Azmi Shariff

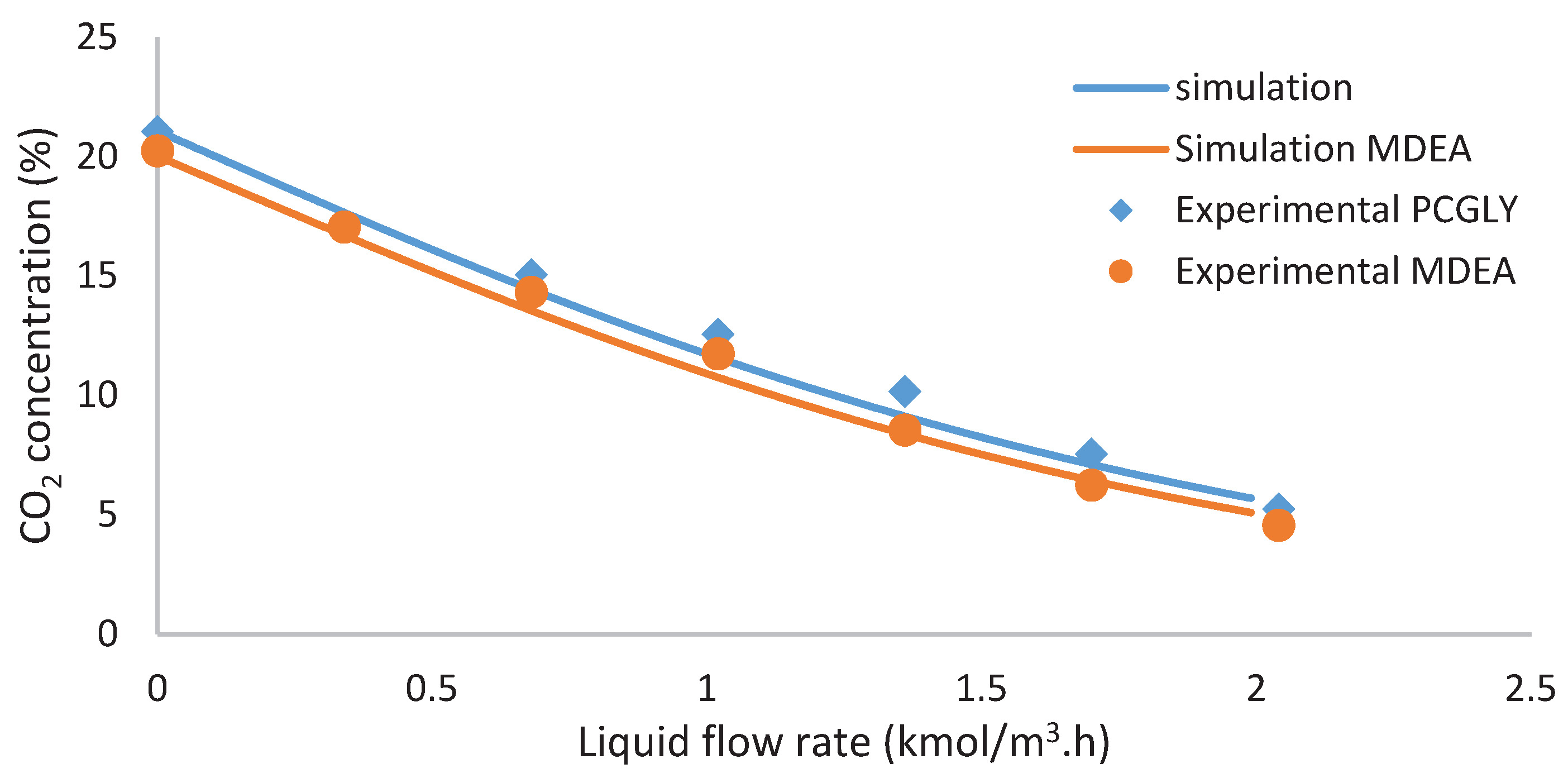

The removal of carbon dioxide (CO2) at offshore operation requires an absorption system with an environmentally friendly solvent that can operate at elevated pressure. Potassium carbonate promoted with glycine, PCGLY, is a green solvent that has potential for offshore applications. For high solvent concentrations at elevated pressure, the by-product of CO2 absorption consists of precipitates that increase operational difficulty. Therefore, this study was done to assess the CO2 absorption performance of non-precipitated PCGLY with concentration 15 wt% PC+3 wt% GLY, which is known to have comparable solubility performance with MDEA. A packed absorption column was used to identify the CO2 removal efficiency, mass transfer coefficient in liquid film, klae and overall volumetric mass transfer coefficient,KGav. A simplified rate-based model was used to determine klae and KGav based on the experimental data with a maximum MAE value, 0.057. The results showed that liquid flow rates and liquid temperature gives significant effects on the klae and KGav profile, whereas gas flow rate and operating pressure had little effect. The CO2 removal efficiency of PCGLY was found to be 77%, which was only 2% lower than 1.2 kmol/m3 MDEA. KGav of PCGLY is comparable with MDEA. The absorption process using PCGLY shows potential in the CO2 sweetening process at offshore.

Posted on: May 2021

Authored: Azmi Shariff