Research Success Stories

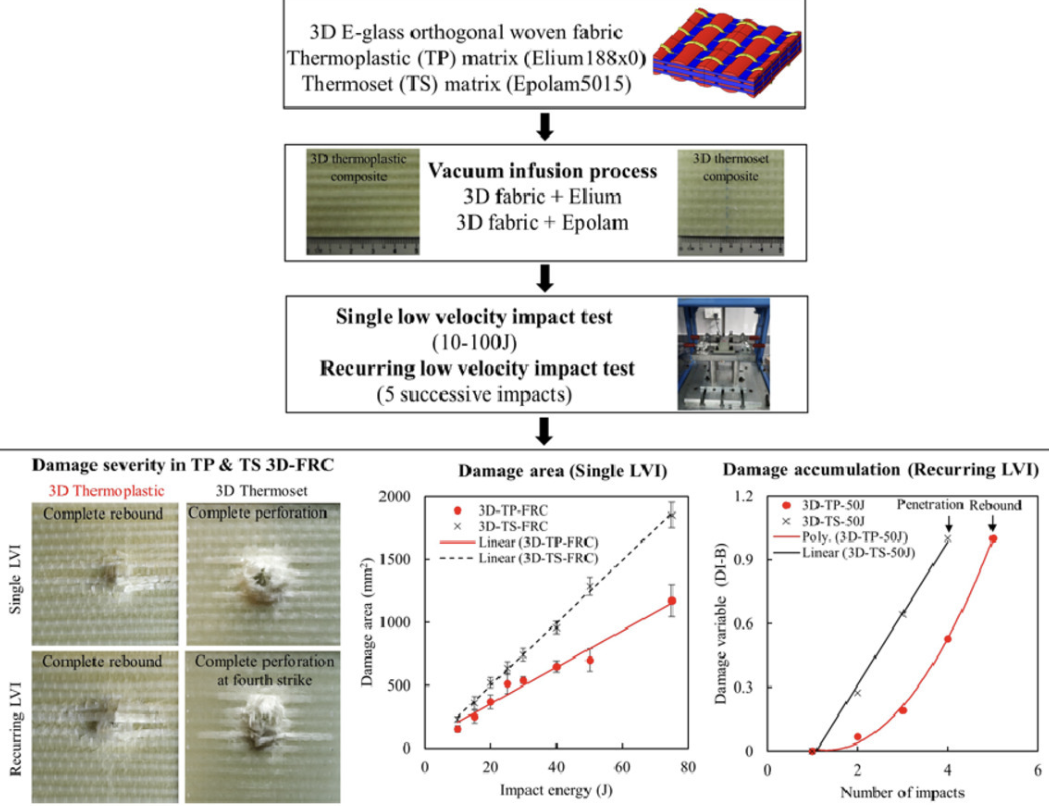

In this paper, the impact performance of a novel resin-infused acrylic thermoplastic matrix-based 3D glass fabric composite (3D-FRC) has been evaluated and compared with thermoset based 3D-FRC under single as well as recurring strike low velocity impact (LVI) events. The single impact tests revealed that the thermoplastic-based 3D-FRC exhibits up to 45% reduced damage area and can have up to 20% higher impact load-bearing capacity (peak force). The damage mode characterization showed that damage transition energy required for micro to macro damage transition is 27% higher, and back face damage extension is up to 3 times less for thermoplastic-based 3D-FRC. Meanwhile, the recurring strike impact test highlights that the thermoplastic-based 3D-FRC experiences a 50% less damaged area, better structural integrity, and survived more strikes. The comparison of single and repeated LVI tests have also allowed us to present a design criterion for estimating the safe number of repeated LVI events for a given impact energy. The superior impact resistance of thermoplastic-based 3D-FRC is attributed to their higher interlaminar fracture toughness, a tougher fiber-matrix interface, matrix ductility, and unique failure mechanism of yarn straining, which is not present in thermoset composites.

Posted on: January 2021

Authored: Faiz Ahmad

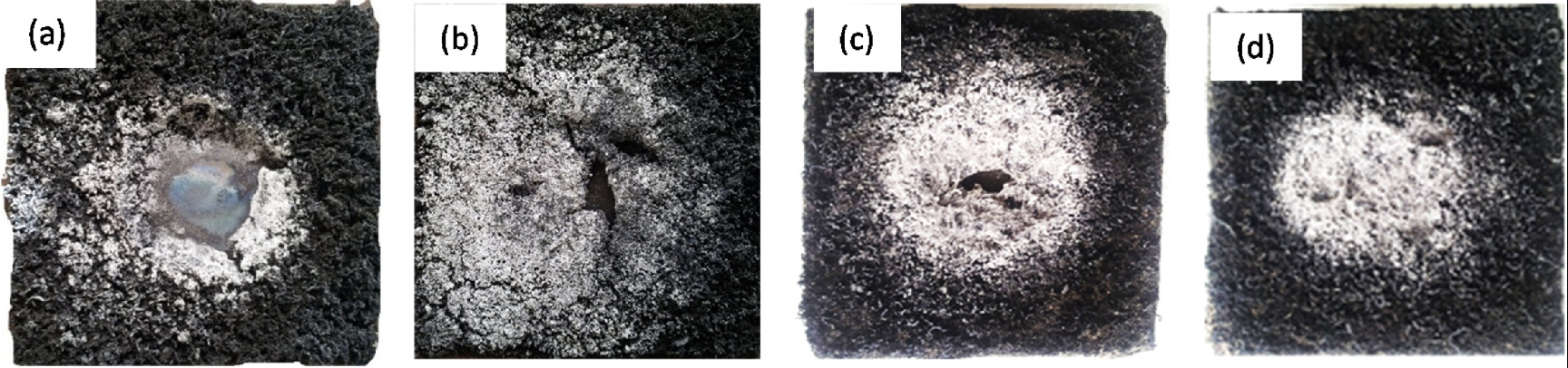

Epoxy-based intumescent coatings are widely used in oil and gas industries, shopping complexes and petrochemical plants to provide fire protection to the metallic substrates during the event of a fire. The present work shows how the incorporation of basalt fibers as filler material in an epoxy-based intumescent coating enhances its thermal insulation property. Dispersing agents (ethanol or glycidyl ether) were also added to the coating and their effects on the dispersion of the basalt fibers and the thermal performance of the coating were also discussed. Bunsen burner (ASTM E119) and expansion tests were performed to study the influence of basalt fibers' dispersion on the thermal insulation property of the coating. Coatings and their chars were also analysed by Field Emission Electron Microscopy (FESEM), Fourier Transform Infrared Spectroscopy (FTIR), X-Ray Diffraction (XRD) and X-Ray Photoelectron Spectroscopy (XPS) analyses. Thermal stability was investigated using Thermogravimetric Analysis (TGA) in the pyrolysis conditions. Fire test results showed that the formulation containing ethanol as dispersing agent provided a higher fire protection, whereby the backside of the steel plate can reach a very stable plateau at 189 ° after 15 min exposure. It is also shown that the coating reached the highest expansion of 1087% with a very homogeneous char structure. The FESEM images also confirmed that basalt fibers were well dispersed when ethanol was used, whereas aggregates were formed when no dispersing agent was added. XRD and FTIR showed that the presence of boron oxide, boron phosphate, carbon and silica in the formulations which are thermally stable can improve the thermal performance of the intumescent coating. Finally, TGA confirmed that the thermal stability of formulations containing dispersing agents has been improved.

Posted on: September 2018

Authored: Faiz Ahmad

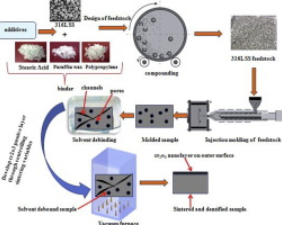

Although various materials have been exploited throughout history to restore damaged organs, metallic biodevices are preferred in the biomedical industry because of their superior ability to withstand high static or cyclic loads. An implant is a medical device manufactured to replace a damaged biological structure. Medical implants are manmade devices and their biocompatibility plays an important role in determine the life of inserted implant. This review presents previous research conducted in the field of corrosion resistance and mechanical properties of bioimplants made of 316L stainless steel (SS) powder using the powder injection molding process. It also establishes a motivational link between the past and present to encourage researchers to conduct constructive studies on the most problematic areas of bioimplants. This article presents a critical review on powder selection, manufacturing techniques, debinding processes, and sintering conditions of 316L SS powders. It also focuses on the influence of powder shape, powder size, powder-to-binder ratios and their effects on densification in terms of corrosion and mechanical properties. In this paper, practical densification approaches are divided into three categories: activation sintering, optimized solid loading, and bimodal mixtures. Additionally, suggestions for the formation of a passive oxide layer on the outer surface of 316L stainless steel implants using powder densification approaches and optimization of sintering parameters are proposed.

Posted on:2016

Authored: Faiz Ahmad

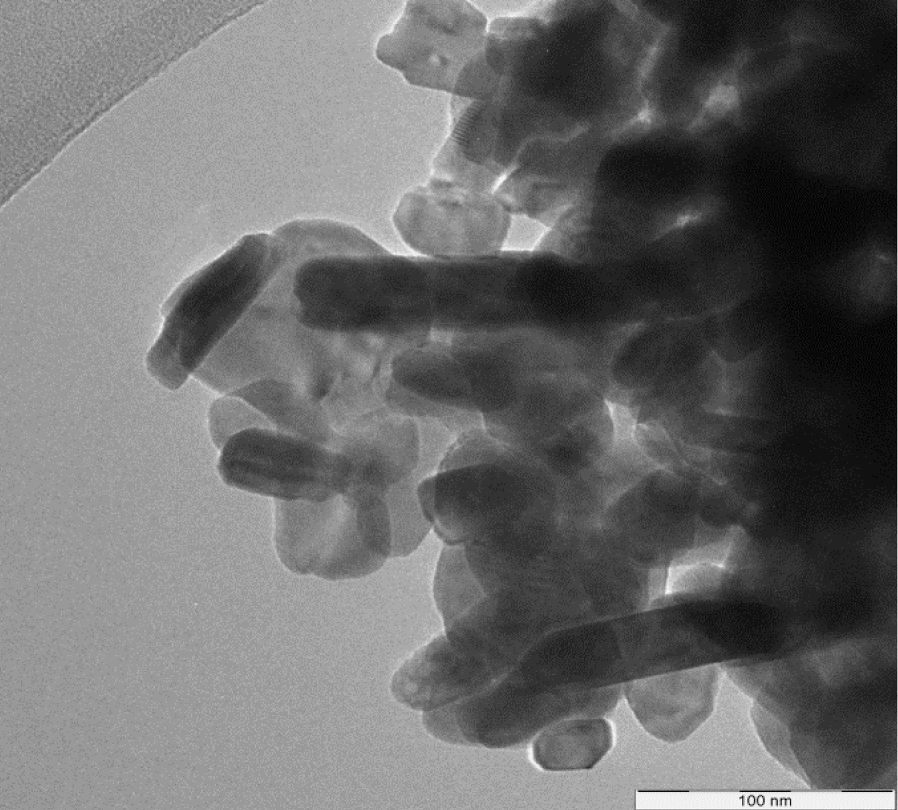

Due to its effective performance, intumescent fire retardant coating (IFRC) is widely used by oil and gas industries as well as in processing and petrochemicals plants to protect metallic substrates from fire. The present work developed an epoxy based IFRC comprising phosphate, nitrogen, barium and boron containing flame-retardants. The product was reinforced with nano-titanium oxide and then examined for performance with a lab scale hydrocarbon fire test. Thermal analysis of the coating was evaluated using TGA and DTGA under nitrogen and oxygen environments. Further characterization studies included FESEDS, FTIR, XRD and XRF to determine effects from nano titanium oxide on char's performance. Results indicated that a coating reinforced with 4.5 wt% of nano-TiO2 added residual weight to the coating and provided longer thermal protection time compared to conventional fire retardant coatings.

Posted on: December 2016

Authored: Faiz Ahmad

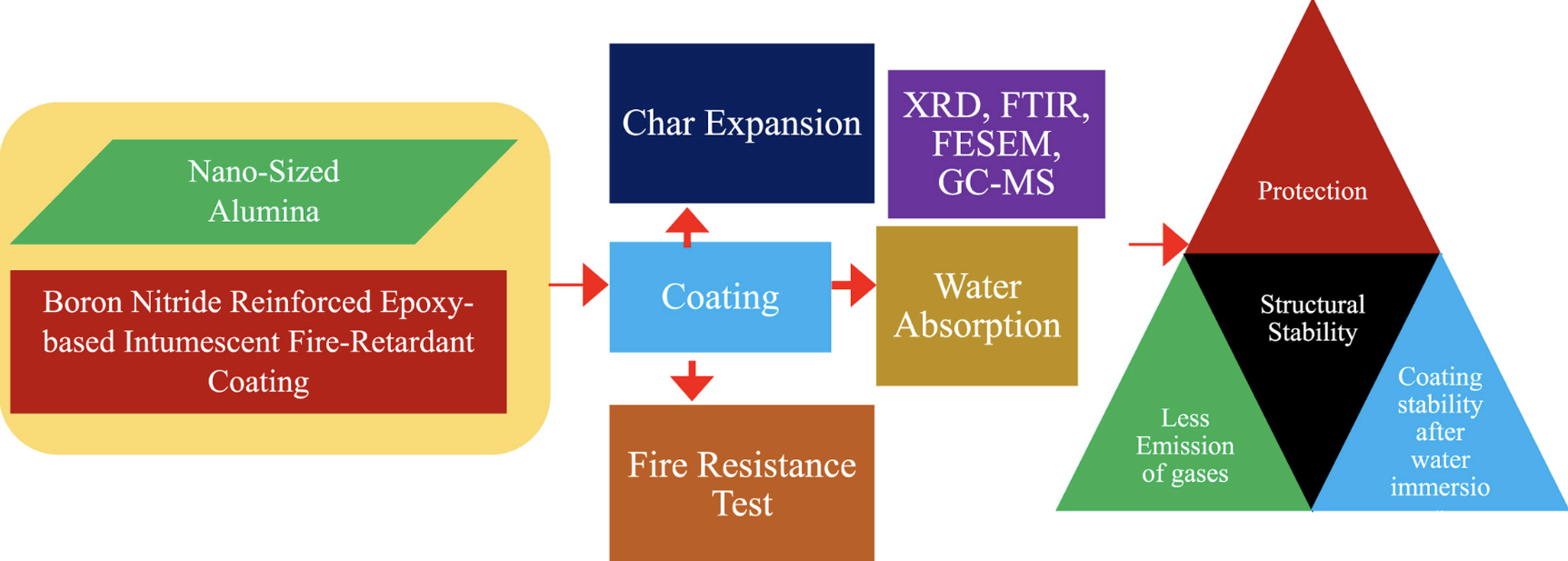

This study presents the fire resistance results of incorporating nano-sized alumina in boron nitride reinforced epoxy-based intumescent fire-retardant coating. Structural steel substrates were coated with the developed coating and exposed at 800 °C for 2 h for furnace fire test to examine the char expansion and morphology. The fire-resistance of the coating was tested by heating the coated substrates using a Bunsen burner for 1 h. The coated substrates were tested for water absorption followed by a fire-resistance test. The furnace fire test showed that boron nitride-alumina (BNA-1) reinforced with 0.1 wt% of nano-sized alumina resulted in 45% higher char compared to boron nitride-alumina reinforced with 0.4 wt% (BNA-4) and boron nitride-alumina reinforced with 0.5 wt% (BNA-5). The increased amount of alumina improved the mass of the char. The lowest substrate temperature of 137 °C was recorded by BNA-5 with a maximum char mass of 43.89 wt%. This was considered due to formation of aluminum oxide and aluminum phosphate on the char surface, reduced char pore size, and increased amount of alumina in the gas emission. X-ray Diffraction (XRD) analysis found boron phosphate, boron nitride, and phosphoric nitride compounds were reliable in protecting the substrate at high temperature. The functional groups of char compounds were observed by FTIR. FESEM micrographs showed the presence of nano-sized alumina. XPS results also suggest that nano-alumina may react with boron nitride and ammonium polyphosphate additives, producing aluminium nitride, boron oxide, and aluminium phosphate that are beneficial to the intumescent process and fire-resistant performance. Pyrolysis GC-MS results showed reduced emission of gaseous product in BNA-5. This concluded that the addition of 0.5 wt% alumina in BNA improved char morphology and increased char mass. No changes in the microstructure and hardness of the substrate were observed after the fire test. The fire resistance of the water-immersed samples showed a small increase in substrate temperature which was within the acceptable range for structural safety.

Posted on: December 2020

Authored: Faiz Ahmad