Effects of cooling rate on mechanical properties and corrosion resistance of vacuum sintered powder injection molded 316L stainless steel

Author: Faiz Ahmad - January 2012

M. Rafi Raza, M.A. Omar, R.M. German

Abstract

This study presents the results of corrosion behavior of powder injection molded 316L stainless steel parts sintered in vacuum. The feedstocks of metal powder and plastic binder were prepared and their viscosity was measured. Green samples were injection molded and binder was removed from the green parts. Brown test parts were sintered at 1325 °C with heating rate of 5 °C/min and 10 °C/min for 2 h followed by the same cooling rate. Corrosion response of the sintered test samples was measured by weight loss method in Ringer's Solution of pH 7.4 for 15 days. The test samples using cooling rate 10 °C/min showed higher mechanical properties and improved corrosion resistance compared to those sintered at low heating and cooling rate. High cooling rate reduced the evaporation of Cr and developed passive chromium oxide layer on the test samples resulting improved corrosion resistance

Methodology

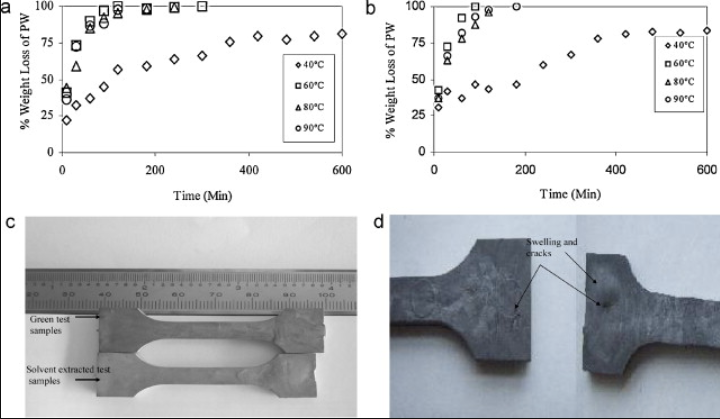

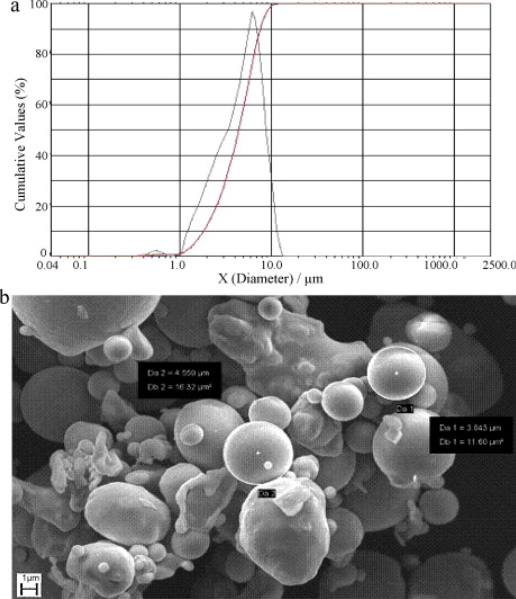

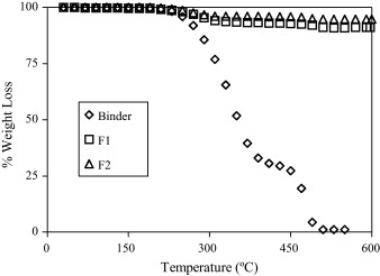

Two formulations F1 (60 vol.%) and F2 (65 vol.%) of stainless steel powders were prepared. The metal powder was dry mixed with a plastic binder containing paraffin wax 70 vol.%, polypropylene 25 vol.% and stearic acis 5 vol.%, followed by mixing in Z-blade mixer at temperature 170 °C for 90 min at 60 rpm. The metal mixtures were dried and granulated by using commercially available granulator. The feed stocks were characterized by using TGA and capillary rheometer CFT-500D. The rheology of the feedstocks was done at temperature 160 °C using a capillary die having the dimension 1 mm x 10 mm. A vertical injection molder100 KSA was used to produce tensile specimens according to MPIF-50 standard. The test samples were produced by injection molding at 160 °C; injection time was varied between 20 and 30 s. No physical cracks were observed on the green parts.

Impact & Benefits

Low-Cost Production: PIM is a cost-effective method for producing complex geometries compared to traditional manufacturing techniques, reducing overall production costs.

Mechanical Properties: The study shows that PIM-produced 316L stainless steel parts exhibit high tensile strength (481 MPa), good elongation (22%), and significant hardness (76 HRB). These enhanced mechanical properties make PIM parts suitable for demanding applications.

Corrosion Resistance: The research highlights the importance of cooling rates during the sintering process, indicating that a higher cooling rate improves the corrosion resistance of 316L stainless steel parts. This is particularly important for applications in harsh environments.

Biomedical Applications: 316L stainless steel's corrosion resistance is crucial for biomedical implants and devices. The ability to achieve high sintered density and resistance to localized corrosion (such as pitting in the presence of chloride ions) is essential for biological applications where corrosion can cause severe health issues.

Automotive and Aerospace Industries: The mechanical properties and the ability to produce complex parts efficiently make PIM suitable for the automotive and aerospace sectors, where precision and performance are critical.

Viscosity Control: The study identifies optimal viscosity ranges for PIM formulations, ensuring the process can produce high-quality parts consistently.

Findings/Figures and Research Data

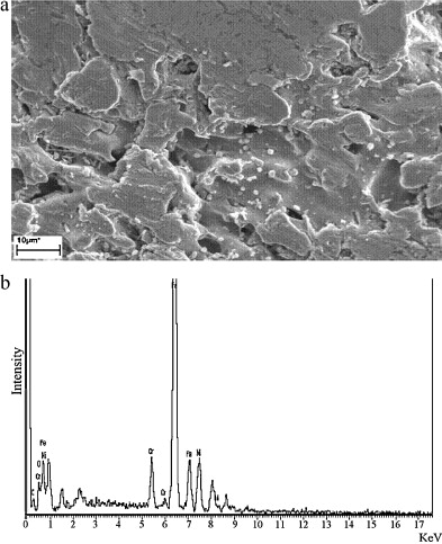

Fig. 10a shows the SEM micrograph of F1 sintered test sample with cooling rate 10 °C/min. The SEM micrograph shows that the test sample has corroded due to the presence of porosity verified in Fig. 10a. The results were also confirmed by EDX analysis that indicates the presence of Ni (Fig. 10b), which causes the corrosion. Fig. 11, Fig. 12 show the SEM micrographs of F2 test samples at different cooling rates. It is observed that the test samples with higher density and mechanical properties have less corrosion than the samples with lower density. In the micrographs, the lighter colored layer is the combination of Fe and O2 while the layer with dark color is the combination of the Cr, O2 and small amount of Ni. These results were confirmed by EDX analysis. Fig. 11, Fig. 12 show the comparison in existence of Cr with O2 in F2 test samples. Fig. 11b shows that the amount of Cr in existence with Oxygen is higher than that shown in Fig. 12b. The presence of more Cr with Oxygen forms the enriched Cr oxide layer, which protects the test sample from the chloride environments.

Market Potential

Complex Geometries: PIM allows for the production of complex geometries at a lower cost compared to traditional manufacturing methods.

Material Versatility: PIM is suitable for both ceramics and metal composites, offering flexibility in application.

Medical and Dental: The ability to produce parts with high corrosion resistance is critical for biomedical applications. The localized corrosion resistance of 316L stainless steel makes it ideal for implants and other medical devices.

Automotive: Complex metal parts with enhanced mechanical properties and corrosion resistance are valuable in automotive manufacturing.

Cost Efficiency: Lower production costs and reduced material waste are significant advantages of PIM.