Quantifying the effects of basalt fibers on thermal degradation and fire performance of epoxy-based intumescent coating for fire protection of steel substrate

Author: Faiz Ahmad - July 2019

Muhammad Yasir, Puteri S.M. Megat-Yusoff, Sami Ullah, Maude Jimenez

Abstract

The thermal properties of residual char of basalt fiber (BF) reinforced intumescent coating (IC) obtained after high temperature burning were studied. Seven intumescent coating formulations were prepared in which the weight percentage of basalt is varied from 0 to 3 wt.% of the total formulation. The effects of BF weight percentage on fire resistance of IC, and char morphology and composition were also studied. The heat barrier effect was analyzed by using a Bunsen burner (ASTM E119). Field emission scanning electron microscopy (FESEM), thermogravimetric analysis (TGA), and X-ray photoelectron spectroscopy (XPS) were used to investigate the IC and residual chars. Furthermore, the thermal conductivity was calculated as a function of temperature to compare the structure and properties of char residues. Intumescent chars with different weight percentages of BFs (in particular formation of pores of different sizes) were firstly verified. The interpretations were not in agreement with the thermal conductivity data. IC-B3 is the formulation that contains 3 wt.% of BF had thermal conductivity value of 0.114 Wm-1 K-1. The morphological study confirmed that 3 wt.% of BF formed a network that protected the underlying steel substrate from temperature rise in the event of fire. TGA results showed that BF reinforced formulations; IC-B3 had 36.26% of residual weight at 800 °C as compared to IC-B0, which had 27 wt.%. Elemental analysis showed that IC-B3 had enhanced carbon content of 63.1% in the residual char. Pyrolysis-gas chromatography-mass spectrometry (Pyrolysis-GCMS) revealed that IC-B3 suppressed the release of toxic gases as compared to IC-B0 and the average percentage of released gases decreased from 83.3%-57.1%.

Methodology

Epoxy resin (NPEL-128) and polyamide amine (PAA) (H-2310) were supplied by WWRC Malaysia Sdn. Bhd., and chosen as the binder and hardener, respectively. Expandable graphite (EG) was purchased from Mc-Growth Chemical Malaysia Sdn. Bhd., and it was used as the physical expansion agent. Ammonium polyphosphate (APP) (Exolit AP422) was supplied by Clariant Malaysia Sdn. Bhd., and it was used as the acid source and swelling agent, while boric acid was supplied by Merck Malaysia Sdn. Bhd., and it was also used as the acid source. The basalt fibers (FBs), which were used as the reinforcing fillers, were imported from JN Technologies Pvt. Ltd. The composition and structural properties of BFs were discussed in our previous article [28]. Lastly, TSA industries provided the mild steel plates S355 (100 X 100 X 1.5 mm3 and 50 X 50 X 1.5 mm3).

Impact & Benefits

Improved Fire Resistance: BFs enhance the mechanical strength and thermal stability of ICs, resulting in a more robust char layer when exposed to fire. This improves the fire resistance of substrates coated with ICs, such as steel structures, by significantly lowering the temperature rise during fire exposure. For instance, the study cited shows a decrease in steel temperature from 275°C to 190°C after 1 hour of fire exposure with just 3% weight of BFs in the IC formulation.

Enhanced Thermal Properties: The thermal conductivity of ICs is crucial in determining their effectiveness in preventing heat transfer to the underlying substrate. Incorporating BFs into ICs reduces thermal conductivity, as demonstrated by the lowest value of 0.114 Wm-1 K-1 for IC-B3 compared to other formulations. This property helps in maintaining lower substrate temperatures during fire events, thus protecting structural integrity.

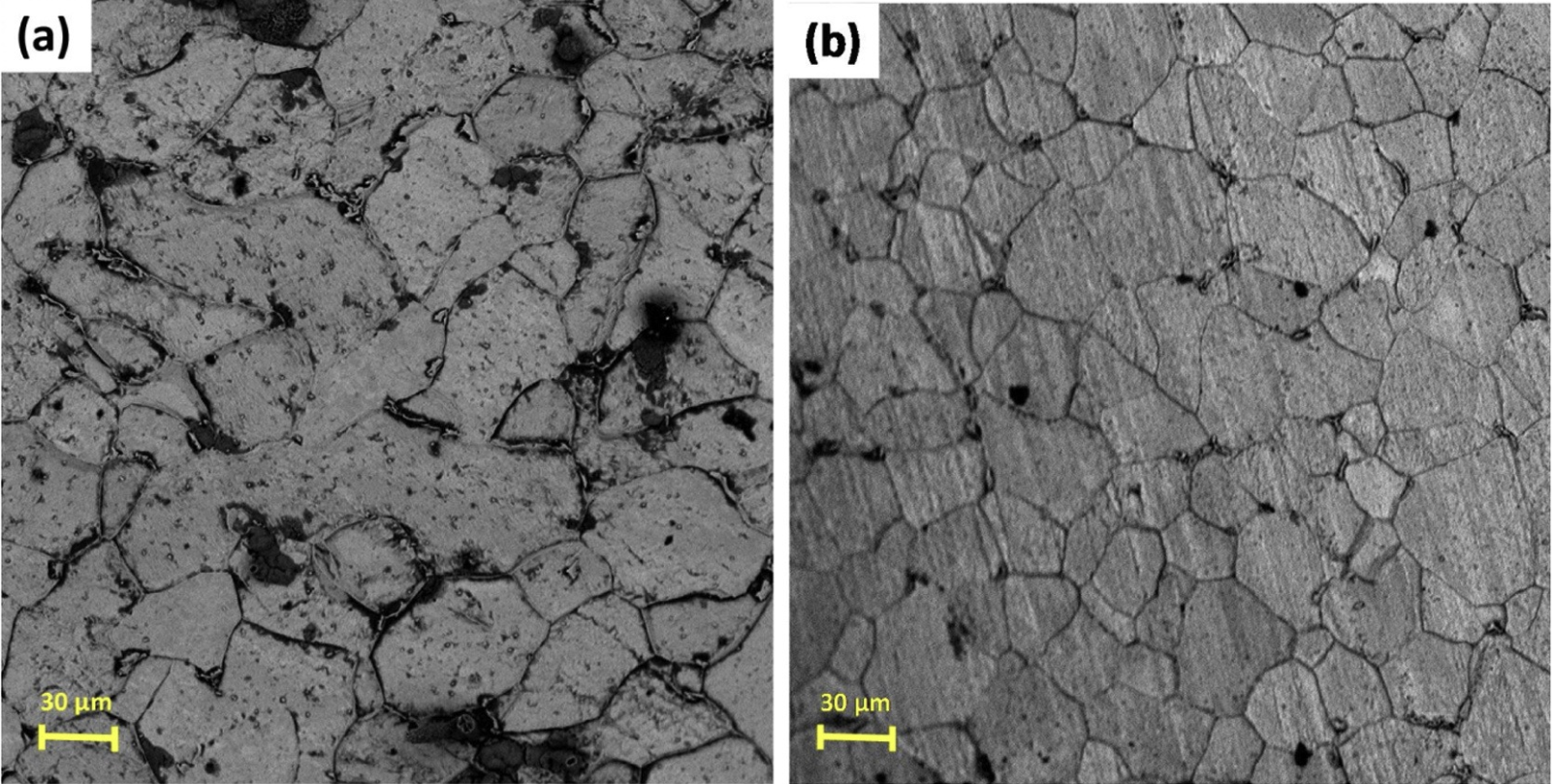

Mechanical Strength and Durability: BFs contribute to the mechanical reinforcement of the char layer formed by ICs. This reinforcement improves the structural integrity of the coating, making it more resistant to cracking and deformation under fire conditions. The denser and more uniform char structure observed in BF-reinforced ICs (IC-B3) compared to control formulations (IC-B0) indicates better mechanical performance.

Reduced Toxic Gas Emissions: Intumescent coatings typically release gases when exposed to fire, some of which can be toxic. By incorporating BFs, particularly at higher percentages as studied, the release of toxic gases can be significantly suppressed. This is critical for occupant safety and environmental impact during fire incidents.

Applications Across Industries: BFs are known for their versatility and are widely used in industries such as automotive, aerospace, and chemical processing due to their strong mechanical properties and corrosion resistance. Incorporating BFs into ICs extends their application potential to these sectors, further expanding market opportunities.

Findings/Figures and Research Data

The aim of the IC is to minimize the slope of the temperature-time curve, i.e., the steel temperature should reach 500 °C as late as possible. The backside temperature of the seven coated steel substrates increases quite quickly (but still slower than the uncoated steel plate) for the first 300 s of the test. Then, the slopes of the curves decrease and some curves even reach a plateau after around 30 min. The reference IC-B0 shows the highest backside steel temperature (275 °C) at the end of the test. The temperature of the samples increases during the first 20 min, corresponding to the time required for the IC to fully degrade and swell. During the next 20 min, the time versus temperature curve reaches a quasi-plateau because the degradation of char occurs at this stage. Moreover, the addition of BF in the formulation leads to a decrease of the backside temperature of the steel by entrapping the hot gases that try to escape from the char [27].

Market Potential

Growing Awareness and Regulatory Requirements: With increasing awareness of fire safety and stricter regulations worldwide, there's a rising demand for effective fire protection solutions. ICs offer passive fire protection by creating insulating char layers, which aligns well with regulatory requirements for building safety.

Diverse Application Areas:ICs can be applied to various substrates such as polymers, textiles, wood, and metals, making them versatile for different industries including construction, automotive, aerospace, and chemical processing. This broad application scope enhances their market reach.

Technological Advancements:Ongoing research focuses on enhancing ICs' performance by improving properties like thermal conductivity, mechanical strength, and fire resistance. Innovations such as incorporating basalt fibers (BFs) to strengthen char layers demonstrate potential improvements in product effectiveness and durability.

Market Size and Growth:The market for fire protection coatings is substantial and growing, driven by industrialization, urbanization, and infrastructure development globally. As economies develop and construction activities increase, the demand for reliable fire protection solutions like ICs is expected to rise.

Research and Development Opportunities: The limited data and ongoing research into optimizing IC formulations (such as with BFs) indicate a fertile ground for further innovation. This includes improving thermal properties, understanding fire behavior scenarios, and developing more accurate modeling techniques for IC performance.