A review of graphene reinforced Cu matrix composites for thermal management of smart electronics

Author: Faiz Ahmad - May 2021

Saad Ali, Puteri Sri Melor Megat Yusoff, Norhamidi Muhamad, Eugenio Oñate, Muhammad Rafi Raza, Khurshid Malik

Abstract

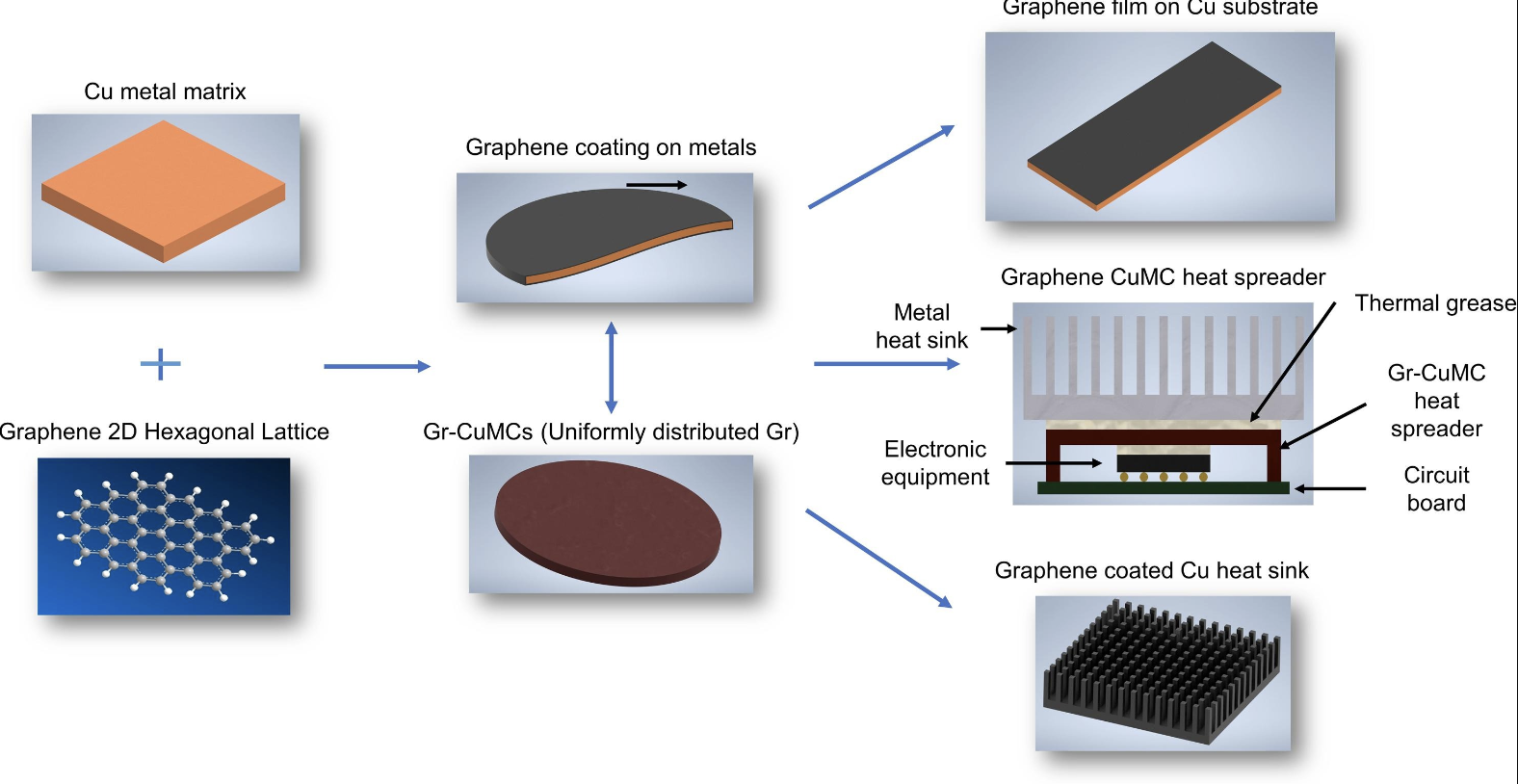

Heat dissipation remains a key challenge to be addressed, determining the performance and durability of smart electronic devices. Graphene reinforced metal matrix composites have been extensively studied as a thermal management material due to their high thermal conductivity and low coefficient of thermal expansion. The emphasis of this review is pivoted on the thermal conductivity enhancement of graphene reinforced Cu matrix composites developed in the recent literature. An overview of factors affecting thermal conductivity of composite namely defect processing route, density, graphene derivative, lateral size, concentration, alignment, graphene/matrix interfacial bonding and graphene modification are discussed. An extensive weightage is given to the processing route as it is the most influential factor in determining the enhancement efficiency. Furthermore, graphene based functional products such as heat spreader and heat sink developed for heat dissipation of electronic devices are also reviewed. Finally, the development and outlook for graphene based Cu composites are presented.

Methodology

Graphene has excellent mechanical, electrical, and thermal properties which makes it a suitable candidate for various industrial applications [33]. Due to these properties, graphene has an edge over other carbonaceous materials such as graphite, diamond, and carbon nanotube. In order to get the advantage of these properties industrially for commercial applications, the synthesis of high quality graphene at a massive scale is highly desired, which is a challenging task. In order to overcome this challenge, several synthesis strategies have been proposed, and a few of these have already been put in action by various manufacturers [34]. Moreover, the incorporation of graphene in metal matrix composites has enhanced the thermophysical characteristics, elastic modulus, tensile strength and wear resistance of composites as compared to monolithic metals [35].

Impact & Benefits

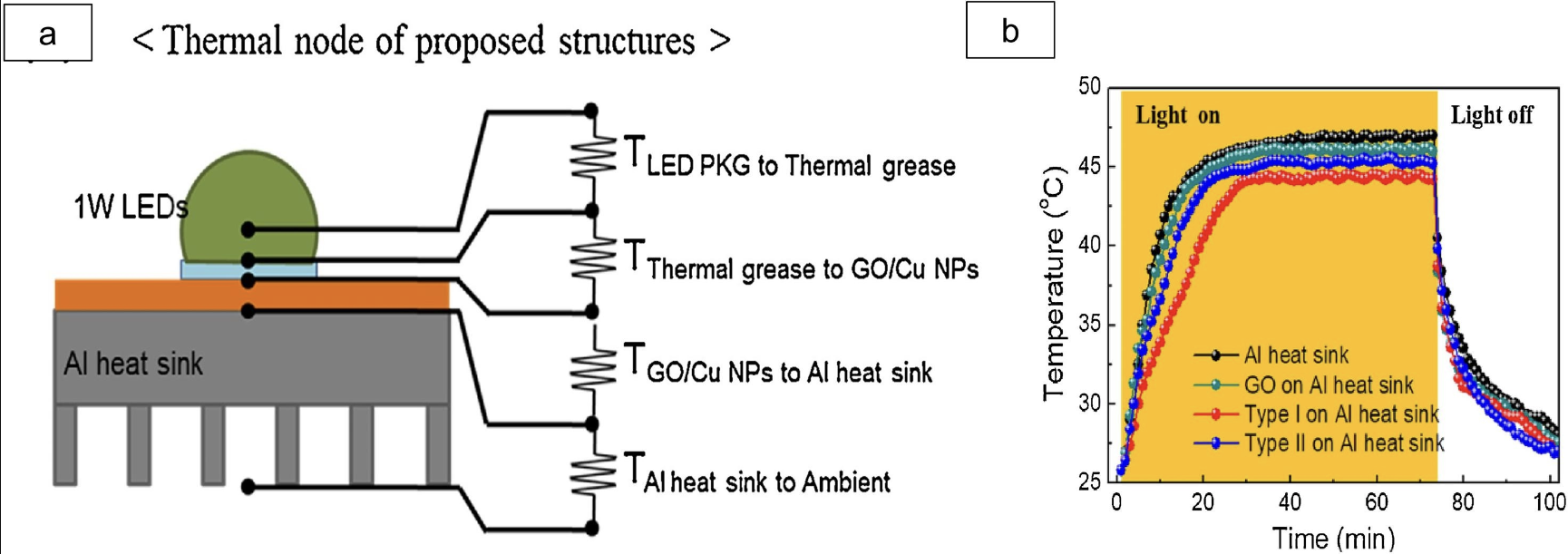

Advancement in Thermal Management Materials: The article highlights the significant improvement in thermal conductivity and thermal management capabilities when using graphene-reinforced composites over traditional metal films. This advancement addresses a critical need in the electronics industry, where heat dissipation is a major challenge due to miniaturization.

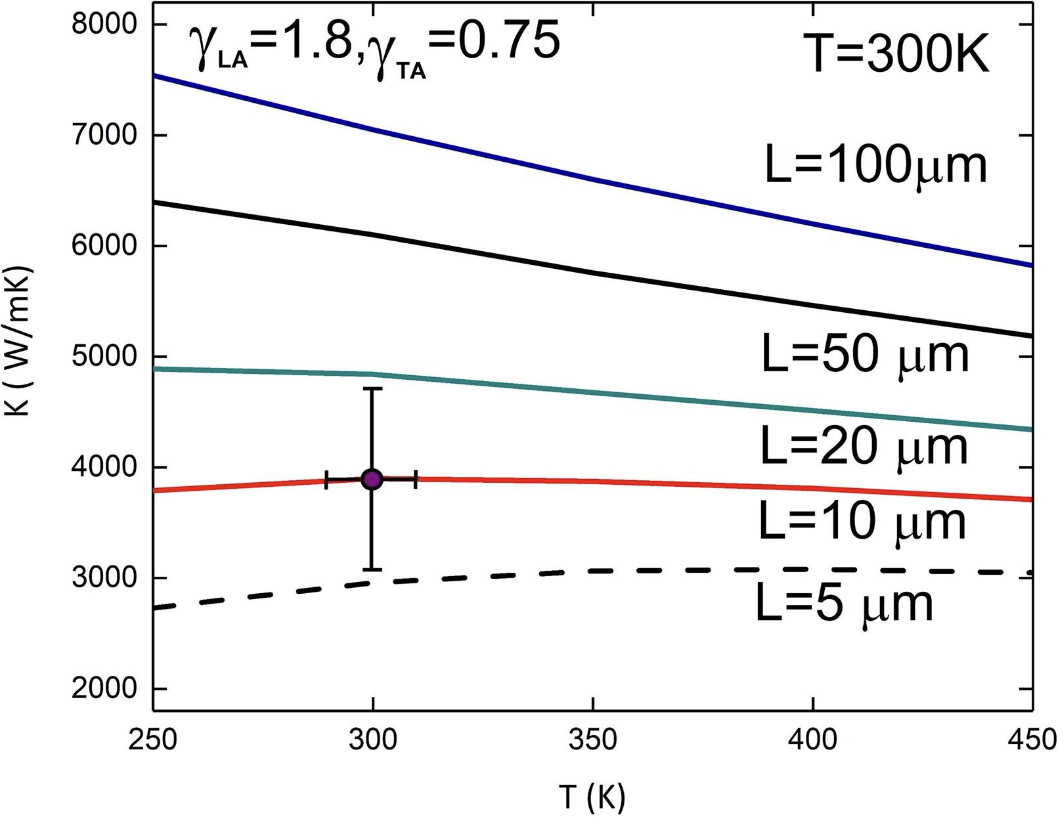

Scientific and Technical Insights: By reviewing the state-of-the-art research on Gr CuMCs, the article provides a comprehensive understanding of the factors affecting thermal conductivity enhancement (TCE). This includes defect density, graphene derivative type, size, concentration, alignment, interfacial bonding, and reinforcement modification.

Enhanced Device Performance and Longevity: By improving heat dissipation, Gr CuMCs can significantly enhance the performance and lifespan of high-performance electronic devices, including laptops, smartphones, smartwatches, and smart glasses. This benefit is crucial for maintaining device reliability and user satisfaction.

Miniaturization Support: The use of Gr CuMCs supports the trend of device miniaturization without compromising thermal management. This allows for the development of smaller, more powerful, and user-friendly electronic devices.

Cost Efficiency: Copper is already widely used due to its cost-effectiveness. Reinforcing it with graphene, which is becoming increasingly affordable, can provide high thermal conductivity at a lower cost compared to using other metals like silver.

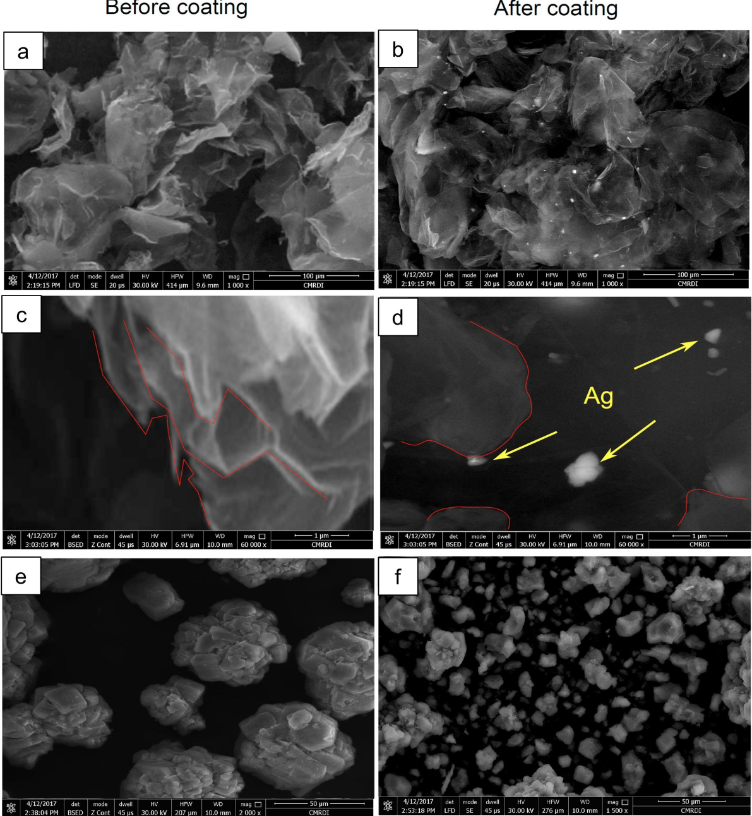

Findings/Figures and Research Data

The synthesis route needs to be redesigned to overcome challenges such as agglomeration, strong graphene/metal interface and to achieve low-cost material for commercial applications. Among fabrication routes, molecular level mixing (MLM) has the advantage of strong interfacial interaction due to molecular level bonding between graphene and metal nanoparticles. Therefore, the nanocomposite synthesized via MLM can be consolidated to develop bulk composite using PIM with flexibility in material, complex shape possibility, low cost, and commercial scalability. Although few research studies are available which utilizes PIM for the synthesis of Gr CuMCs, however, this is still in its initial phase. PIM will facilitate low-cost fabrication of complex geometry composite specimens with minimum defects, flexible material choice and without any post processing requirement. Furthermore, there is a possibility for the combination of molecular level mixing and metal additive manufacturing techniques to fabricate low-cost complex geometry parts. At the same time, other advantages of additive manufacturing include less throughput time, flexible, and ease of scale-up.

Market Potential

Miniaturization and High Performance Requirements:Modern electronic devices are becoming smaller and more powerful, leading to increased heat generation within compact spaces. Effective thermal management solutions are critical to prevent overheating and ensure the longevity and performance of devices such as laptops, smartphones, smartwatches, and smart glasses.

Superior Thermal Properties of Graphene:Graphene and other carbonaceous materials exhibit high thermal conductivity, making them excellent for heat dissipation. Their use can significantly improve the thermal management of electronic devices compared to traditional metal-based solutions.

Emerging Applications:The rise of wearable technology, the Internet of Things (IoT), and more sophisticated consumer electronics increases the demand for advanced thermal management materials. These applications require compact, efficient, and reliable cooling solutions.

Electronics Industry:The global consumer electronics market was valued at over $1 trillion in 2020 and is expected to grow steadily. Thermal management is a critical aspect of this market, driving demand for advanced materials like Gr CuMCs.

Graphene Market:The global graphene market was valued at approximately $120 million in 2020 and is expected to grow at a compound annual growth rate (CAGR) of over 30% from 2021 to 2028. The use of graphene in thermal management applications will contribute to this growth.