Optimization of magnetite with modified graphene for microwave absorption properties

Author: Faiz Ahmad - March 2023

Saba Ayub, Beh Hoe Guan, Hassan Soleimani, Kok Yeow You, Zaib Un Nisa, Jemilat Yetunde Yusuf, Mohamad Amin Bin Hamid

Abstract

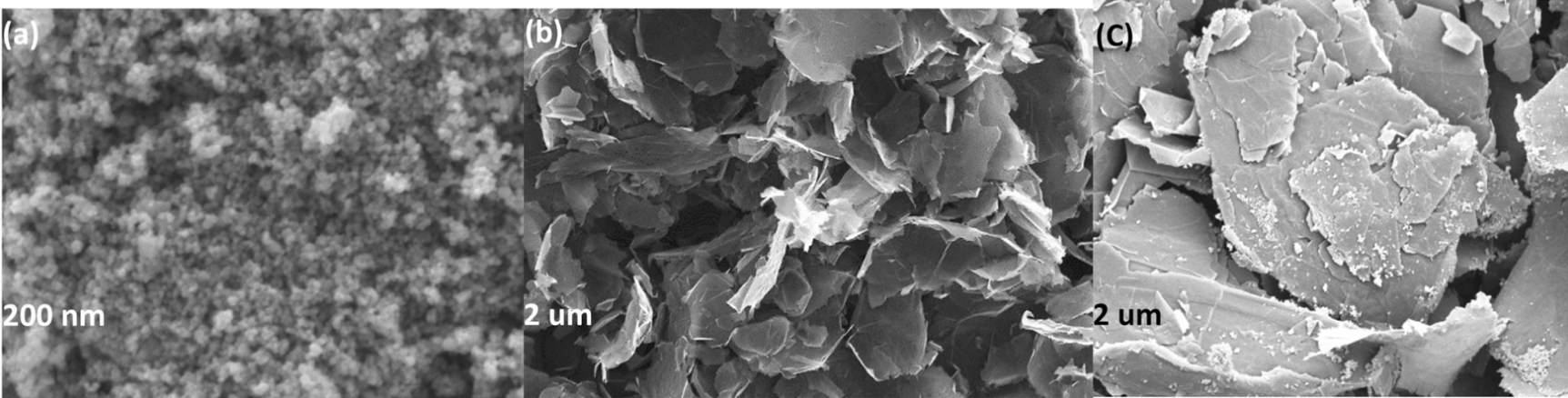

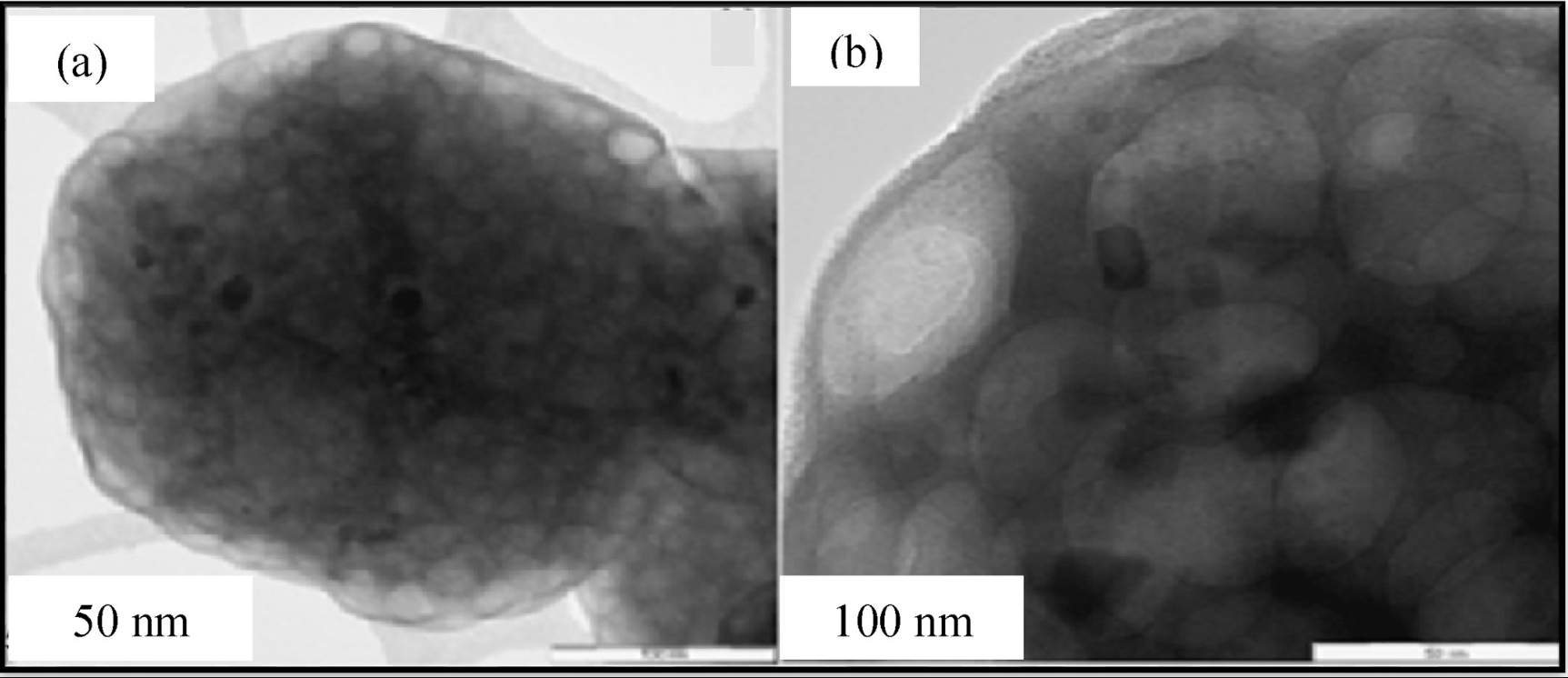

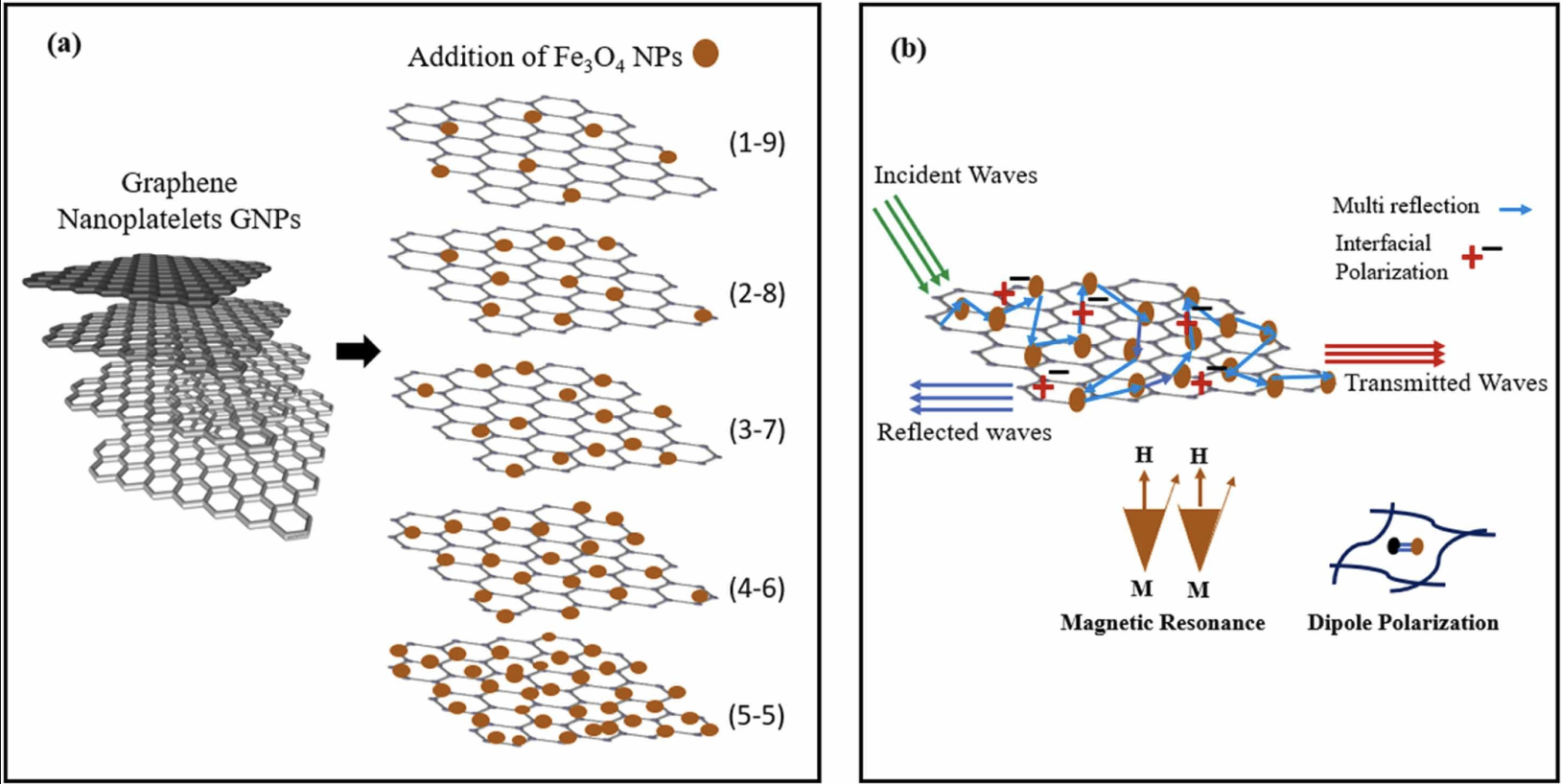

Nowadays, the demand for microwave absorption materials (MAMs) is intensifying in response to the rising sensitivity of electromagnetic pollution and the need for contemporary military security. Therefore it is crucial to develop outstanding performance MAMs. In this study, magnetite-modified graphene (MMG) was synthesized using the solvothermal method by varying the amount of magnetite with graphene nanoplatelets. Later, to optimize the best-suited proportion at which maximum microwave absorption properties were achieved. The structural morphology, phase crystallinity, and chemical composition of the MMG composites were investigated. The morphology reveals that magnetite particles are firmly attached to the edges of the graphene nanoplatelets (GNP). For the microwave absorption investigation, the permittivity, permeability, and reflection loss values of the composite absorbers were measured with a vector network analyzer. The reflection loss of the MMG with a low filler proportion reaches -56.64 dB at a frequency 11.7 GHz and bandwidth 2.16 GHz at a thickness of 3 mm. The sample (3-7) was most suitable for good microwave absorption properties.

Methodology

The materials used in this study are magnetite iron oxide (Fe3O4) with an average particle size less than 30 nm and molecular weight 231.54 g/mol, graphene nanoplatelets (GNP) grade H with a thickness of 15 nm, surface area 50-80 m2/g, and molecular weight 12.01 g/mol, ethylene glycol solvent and paraffin wax which were purchased from Sigma Aldrich.

Impact & Benefits

Enhanced EMI Shielding Performance The integration of magnetite with graphene nanoplatelets significantly improves microwave absorption capabilities, achieving a high reflection loss of -56.64 dB at 11.70 GHz with a bandwidth of 2.16 GHz at just 3 mm thickness. This marks a substantial improvement over traditional materials.

Weight Reduction This weight reduction is particularly advantageous in applications such as aerospace, automotive, and portable electronics, where minimizing weight is crucial for performance and efficiency.

Broader Frequency Range This broad absorption range ensures that the material can be used in diverse environments and applications, including different frequency bands used in communications, radar, and other electronic systems.

Improved Material Stability and Durability: Products and systems incorporating these materials will have extended lifespans and reduced maintenance costs, improving overall reliability and cost-effectiveness.

Health and Environmental BenefitsImproved health outcomes and compliance with stringent environmental and safety regulations can be achieved, enhancing the well-being of individuals and communities.

Findings/Figures and Research Data

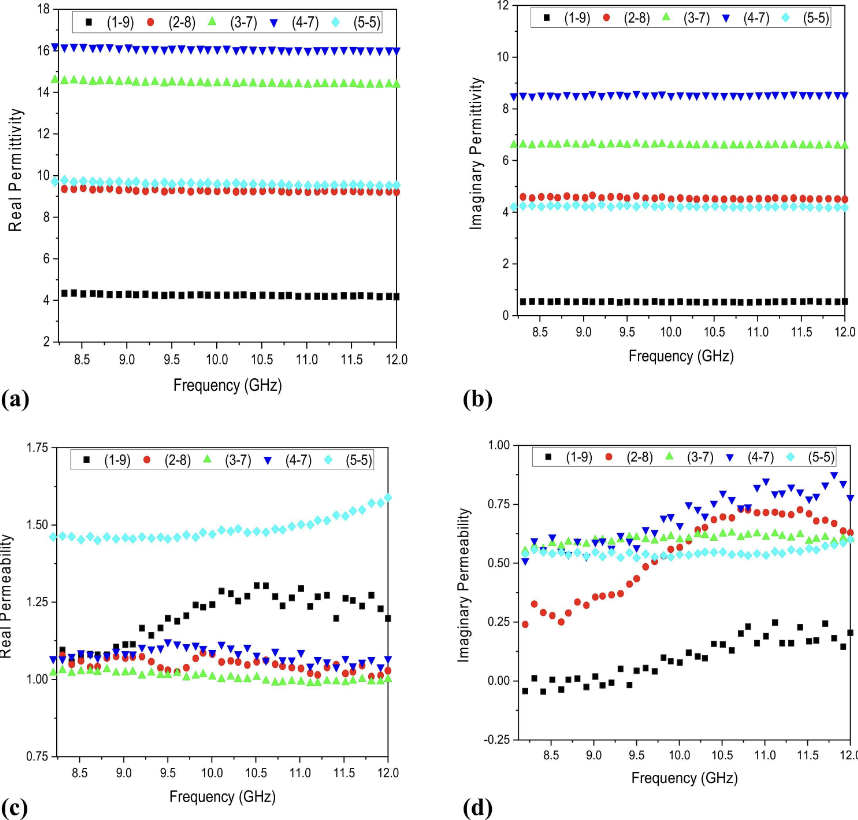

The relative permeability and permittivity of the material were investigated from 8.2 to 12 GHz. With these obtained EM wave characteristics, (2), (3), (4) were used to determine the reflection loss (RL) that represents the magnitude of the samples.Composites' dielectric characteristics are critical in attenuating EM radiation. When an electric field is applied to this composite material, the electric charge carriers are rearranged, polarized, and aligned with the applied electric field. Permittivity in the complex domain is composed of two components: real and imaginary permittivity.

Market Potential

Increasing Demand for EMI Shielding:With the proliferation of electronic devices, including smartphones, laptops, IoT devices, and more, there is a growing need for effective EMI shielding to prevent interference and ensure reliable device operation. This drives the demand for advanced MAMs that can provide effective shielding solutions.

Growth in Consumer Electronics and Communication Industries:The rapid expansion of the digital electrical and intelligent electronic communication sectors necessitates robust EMI management solutions. The market for consumer electronics, in particular, is expected to continue growing, thereby increasing the demand for innovative EMI shielding materials.

Industrial Applications:Industries such as automotive, aerospace, defense, and telecommunications require advanced EMI shielding to protect sensitive equipment and ensure the integrity of electronic systems. The push towards electric and autonomous vehicles further amplifies this need.

Health Concerns and Regulatory Pressures:There is a growing awareness of the potential health risks associated with prolonged exposure to electromagnetic radiation. This, coupled with stringent regulatory requirements for EMI and electromagnetic compatibility (EMC), fuels the need for advanced MAMs.