Thermal and pyrolysis analysis of minerals reinforced intumescent fire retardant coating

Author: Faiz Ahmad- April 2018

M. Zia-ul-Mustafa, Sami Ullah, Norlaili Amir, Qandeel Fatima Gillani

Abstract

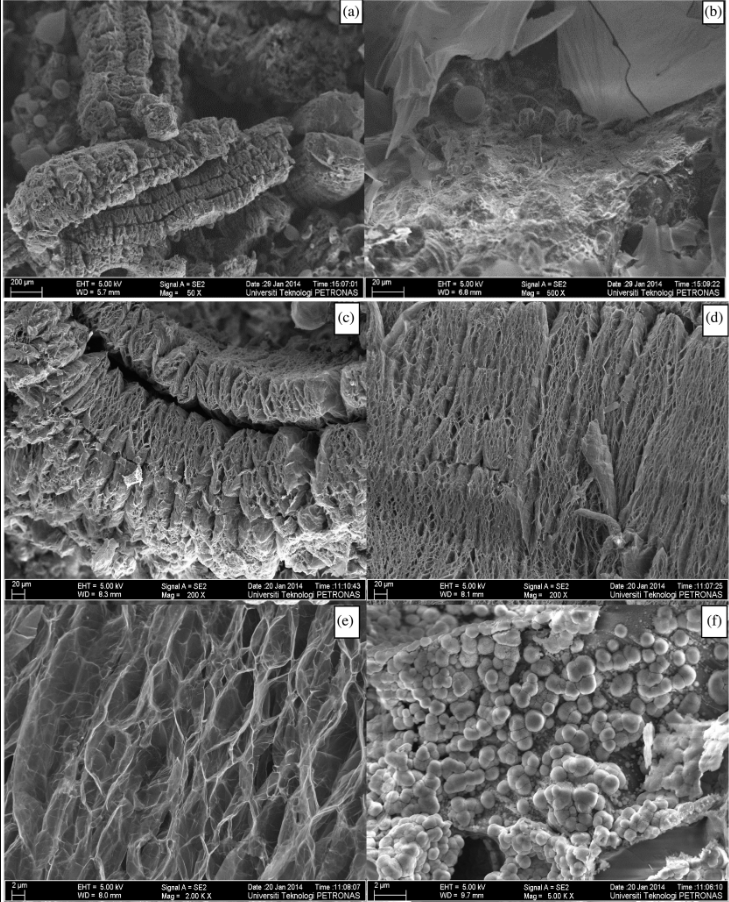

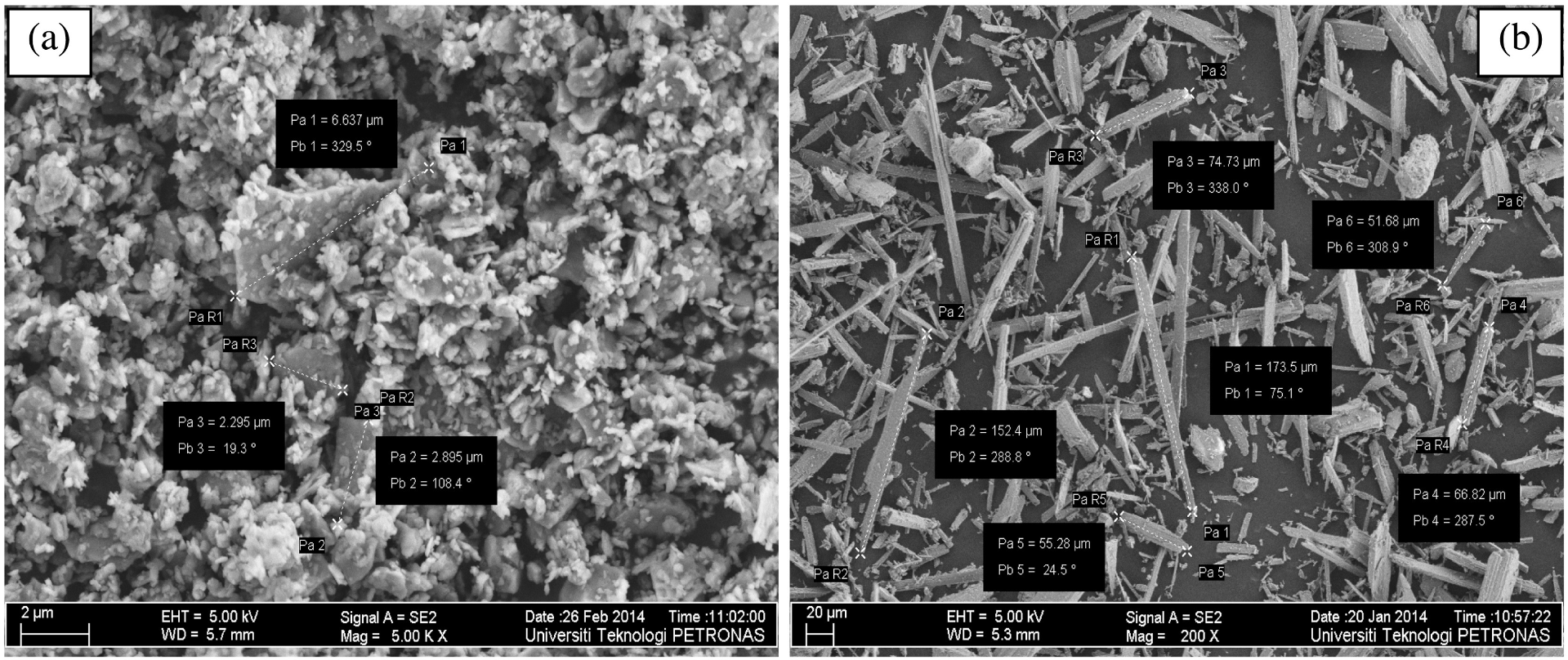

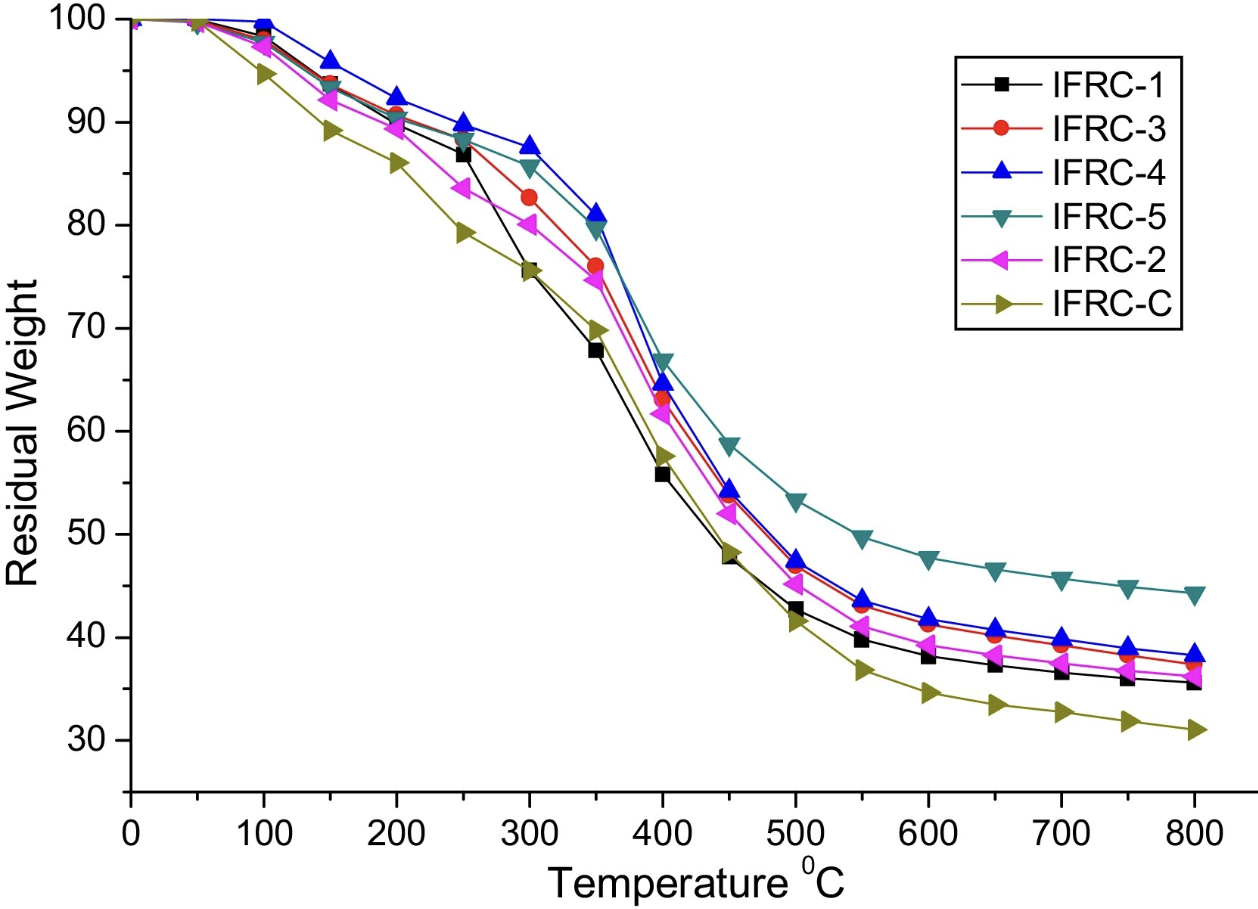

This study presents the results of intumescent fire retardant coatings (IFRCs) developed to investigate the synergistic effects of mineral fillers (clay and wollastonite) based IFRC towards heat shielding, char expansion, morphology, composition, gaseous products and residual weight. The fire test has been performed to study the heat shielding effect of IFRCs on the substrate using UL-1709 standards. The results showed the synergistic effect of clay and wollastonite using 5 wt.% enhanced the fire protection, performance with recorded substrate temperature 113 °C after 1-h fire test. Field Emission Scanning Electron Microscopy (FESEM) and High-Resolution Transmission Electron Microscopy (HRTEM) showed the micrograph of compact char structure that increased char integrity due to the presence of inorganic fillers. X-ray Diffraction (XRD) and Fourier Transform Infrared Spectroscopy (FTIR) results showed the presence of boron phosphate, silicon phosphate oxide, aluminum borate in char that improved the thermal performance of IFRC up to 800 °C. X-Ray Photoelectron Spectroscopy (XPS) confirmed that 5 wt% (IFRC-5) of clay and wollastonite increased the carbon content up to 50.67%, lowering oxygen content to 27.73% in the char that enriched the fire resistance performance of the coating. Pyrolysis-Gas Chromatography-Mass Spectrometry (Pyrolysis GC-MS) confirmed that formulations IFRC-5 released less gaseous product concentration compared to IFRC-C and maximum reduction in gases was recorded from 3.4e+07 to 1.08e+07. Thermogravimetric analysis (TGA) demonstrated in residual weight was increased to 46.45% for IFRC-5 which resulted in the high thermal stability of the coating.

Methodology

Six formulations of intumescent coatings were successfully synthesized and are presented in Table 1. Accurately weighed amount of coating ingredients were mixed using a shear mixer at 20 rpm at room temperature. The weight ratio of epoxy binder and intumescent flame retardants was maintained 2:1 in all formulations. Furthermore, the weight ratio of APP, EG, MEL, BA was maintained in 2:1:1:2 respectively. The percentage of fillers were substituted with an epoxy binder, as epoxy and hardener do not affect significantly on fire retardant behavior [40]. While weight ratio of APP, EG, MEL and BA was maintained in all formulations due to their meaning in improving fire retardant. All solid ingredients were mixed with epoxy for 20mins and in last 10 min, hardener was added to the mixture to avoid curing of epoxy during mixing. The coating was applied on sandblasted steel plates using a brush. The applied coating was allowed to cure for two days.

Impact & Benefits

Enhanced Fire Retardancy: The addition of minerals significantly improves the fire retardant properties of the coating. This enhancement is crucial for applications in various industries, particularly in construction and transportation, where fire safety is paramount.

Thermal Stability: The study demonstrates how minerals can improve the thermal stability of the intumescent coating, allowing it to maintain its protective properties at higher temperatures.

Improved Material Properties: Reinforcing intumescent coatings with minerals can lead to better mechanical properties, including increased durability and resistance to physical wear and tear.

Cost-Effectiveness: Minerals such as expandable graphite, clay, and metal hydroxides are often cost-effective additives that can enhance performance without significantly increasing the overall cost of the fire retardant system.

Market Potential

The study on mineral-reinforced intumescent fire retardant coatings (IFRCs) highlights substantial market potential across various sectors, such as construction, transportation, and industrial applications, due to their superior fire protection, thermal stability, and environmental benefits. The demonstrated improvements in fire resistance, thermal performance, and emission reductions align well with stringent fire safety regulations and sustainability trends, making these coatings highly attractive to manufacturers and builders. The enhanced mechanical properties, cost-effectiveness, and potential for insurance incentives further bolster their market appeal, positioning these advanced IFRCs as a competitive and valuable solution in the marketplace.