Research Success Stories

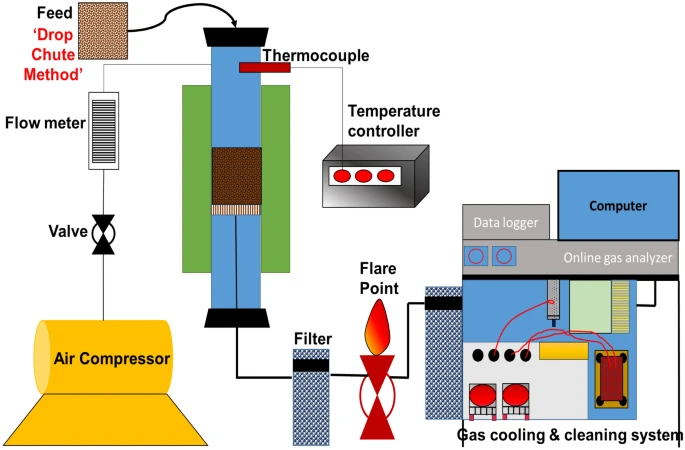

The paper is an experimental study of the gasification process of sawdust (SW), sawdust pellet (SWP) and sub-bituminous coal (SBCoal) by using downdraft gasifier. The gasification was undertaken in a lab-scale fixed-bed gasifier operating under air as an oxidizing agent. The comparison on the raw biomass, treated biomass and coal was assessed in term of the product gas and gasification performance at a fixed condition of gasification temperature of 750 °C and equivalence ratio of 0.25. The gasification performance was tabulated in the form of calorific value of the syngas (HHVsyngas), gasification efficiency (XCGE) and carbon conversion efficiency (XC). It was denoted that SWP produces the highest H2 and the lowest CO2. Furthermore, SBCoal possesses the highest gasification performance among the three feedstocks. Besides, the influence of the temperature between SW, SWP and SBCoal was evaluated at the equivalence ratio of 0.25. The findings demonstrate that rising the temperature, H2 and CO for SW, SWP and SBCoal are increase. The volume of the CO2 is constant as the temperature increases. In contrast, the CH4 decreases with increase in the gasification temperature. As the gasification temperature increases, HHVsyngas and XCGE of SW and SWP are increasing; meanwhile, SBCoal shows the opposite results. Simultaneously with rising gasification temperature, the XC's of the SW, SWP and SBCoal are increasing.

Posted on: August 2020

Authored: Shaharin Anwar Sulaiman

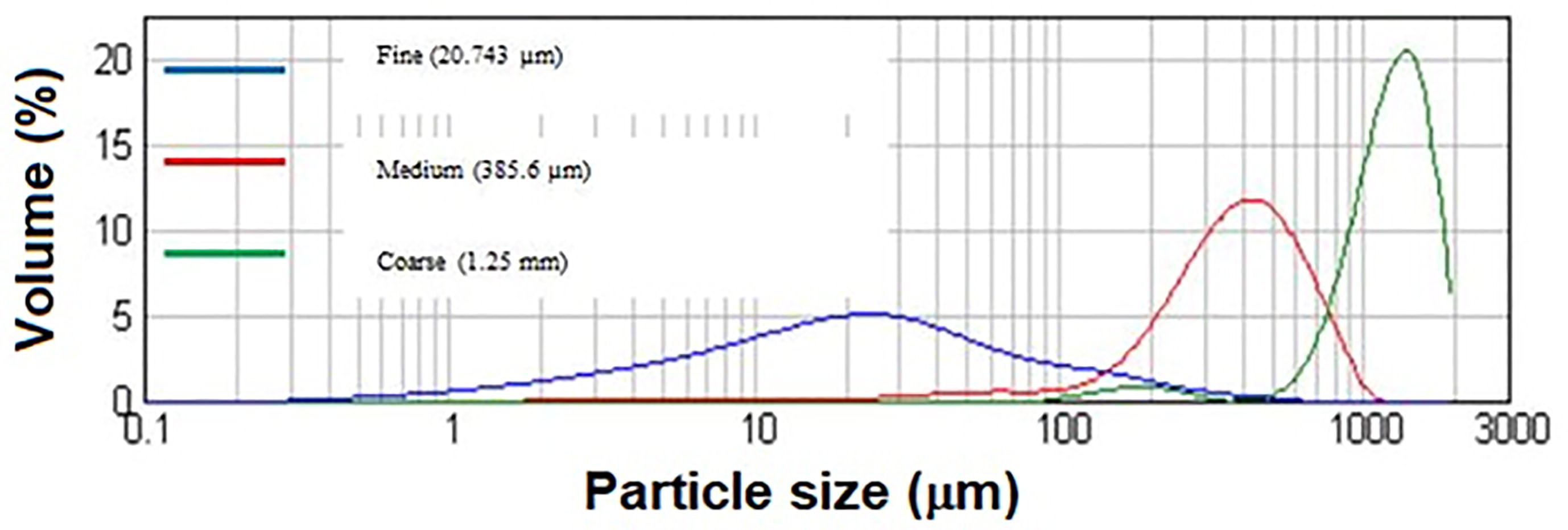

One of the most important aspects of drilling mud is the optimization of particle size of bridging agent. The bridging agent is deliberately sized to minimize the fluid loss into the reservoir and to control the permeability near the wellbore. The objective of this study is to visualize the invasion depth of drilling mud particles into the formation and to evaluate the effects of bridging agent particle size and distribution on permeability and porosity near wellbore. Calcium carbonate was used as a bridging agent. It is important to know the severity of formation damage caused by the drilling mud to attain maximum production over a long period of time. This paper describes an experimental approach to study the effects of bridging agent particles in drilling mud on formation damages. The work was performed by changing the size of bridging agent particles from fine to medium and medium to coarse. It was observed that the calcium carbonate size should be almost identical to the pore throat median size of the formation face. The minimum reduction in permeability was noticed when pore spaces were covered with bridging particles, which prevent the fluid loss into the formation.

Posted on: January 2021

Authored: Shaharin Anwar Sulaiman

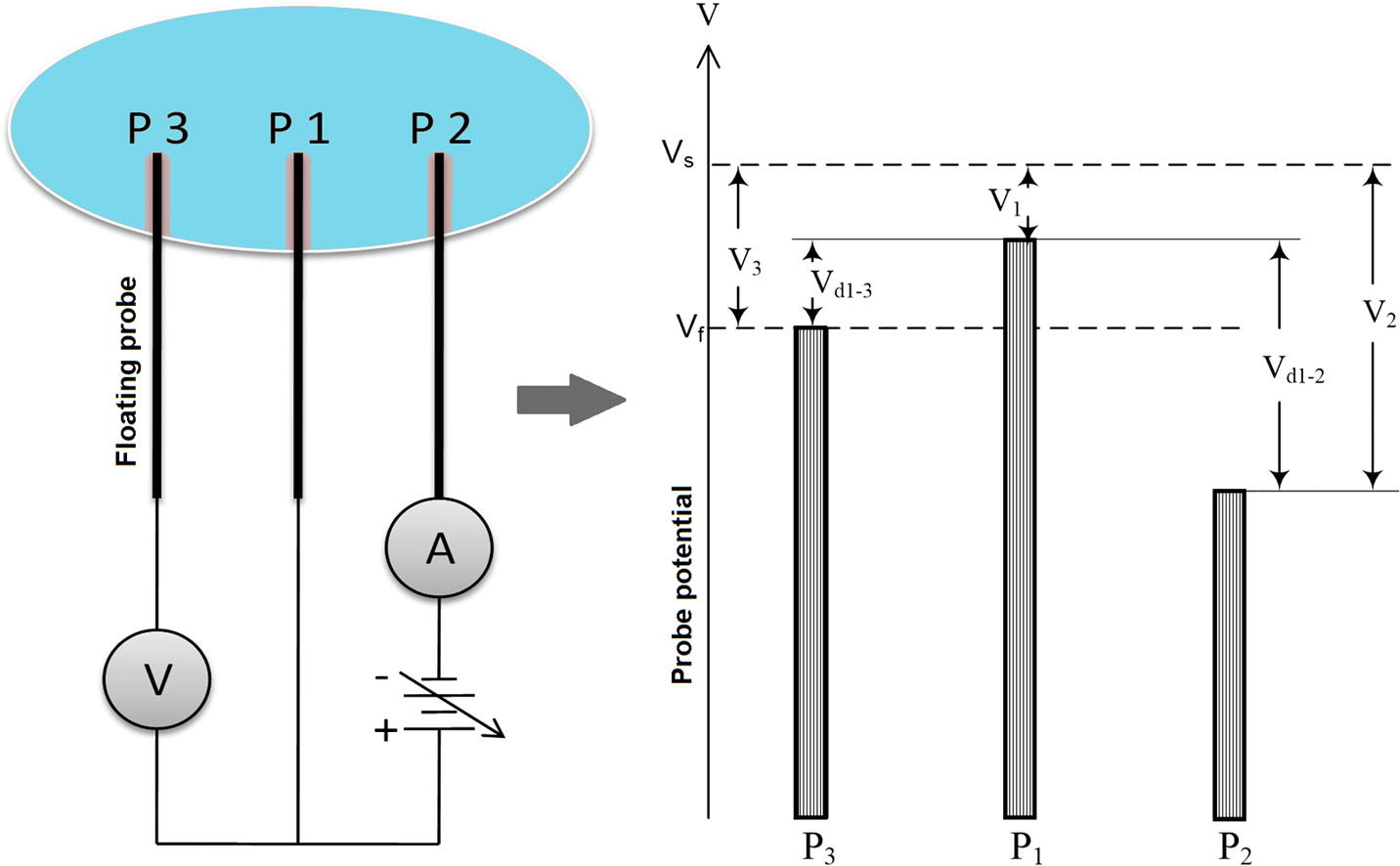

This study investigated the workability of a NiCr wire probe diagnostic under low temperature plasma operating conditions. The aim of the work was to design and fabricate a triple Langmuir probe with NiCr alloy for measurements in low temperature rf plasmas. The spatial distribution of electron temperature and number density were evaluated at different filling pressures in the range of 0.2-0.4mbar and rf powers in the range of 200-400W. The probe data revealed a linear increase in temperature and electron number density with rf power along the chamber centerline, whereas an inverse relationship was found between the given plasma parameters and filling gas pressure. The spatial distribution measurements showed a decreasing trend in plasma parameters at positions away from the chamber centerline. The probe I-V characteristics curve revealed a change in polarity of probe potential with an increase in current supply from the plasma discharge to the probe. Initially, the potential difference raised from highly negative values to zero volt, thereafter started increasing positively. It is found that the response of NiCr alloy as probe material was appreciably good under the proposed operating conditions.

Posted on: September 2016

Authored: Shaharin Anwar Sulaiman

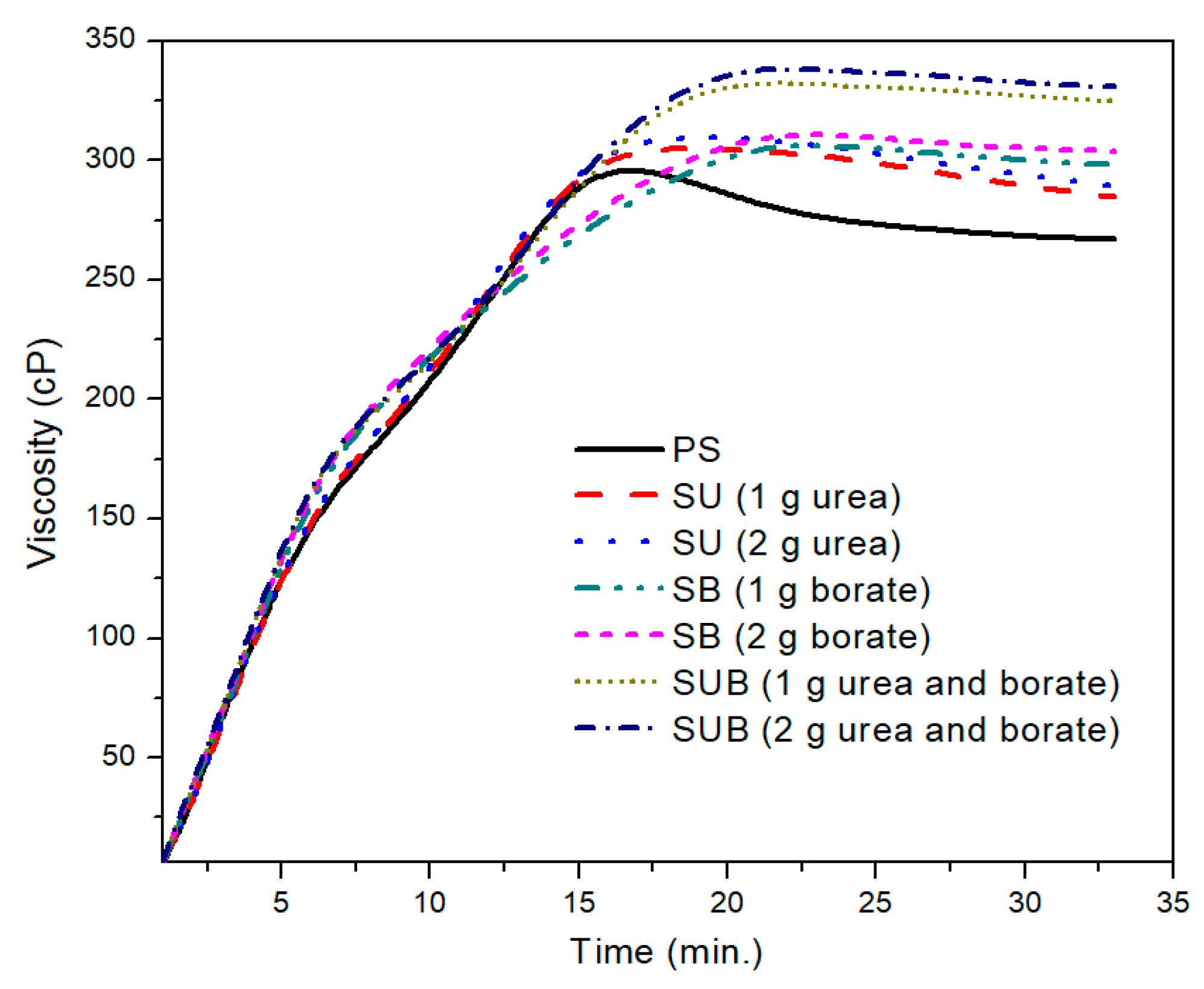

Although starch based materials have an array of fascinating industrial applications, the native starches do not show good mechanical strength, thermal stability, and rheological properties for their use in the mainstream processing industry. For example, the use of starches for producing controlled release fertilizers is a new research endeavor with detailed knowledge still to come. The thermal processing of native starches with water as a plasticizer results in poor physical and pasting properties of the final product. Therefore in this study, corn starch was thermally processed with urea and borate in a water medium. The pure starch (PS), starch-urea (SU), starch-borate (SB), and starch-urea-borate (SUB) samples were prepared and characterized for their rheological traits. The PS sample exhibited a peak viscosity of 299 cP after 17 min of thermal processing. Further heating of the suspension caused a decrease in viscosity of 38 points due to thermal cracking of the starch granules. A similar trend was depicted in the viscosity measurements of SU, SB, and SUB adhesives. However, the viscosity of these samples remained slightly higher than that for PS. Also, the reduction in viscosity after the peak value was not as notable as for PS. The modified starch behaved like a gel and its storage modulus was significantly higher than the loss modulus. The lower magnitudes of storage and loss moduli revealed that the modified starch was in the form of a weak gel and not a solid. The PS is more fluid in nature with dominating loss modulus at lower angular frequencies.

Posted on: September 2017

Authored: Shaharin Anwar Sulaiman

Posted on: May 2023

Authored: Shaharin Anwar Sulaiman