Role of particle size distribution of bridging agent for drilling mud on formation damage near wellbore

Author: Shaharin Anwar Sulaiman - January 2021

Abstract

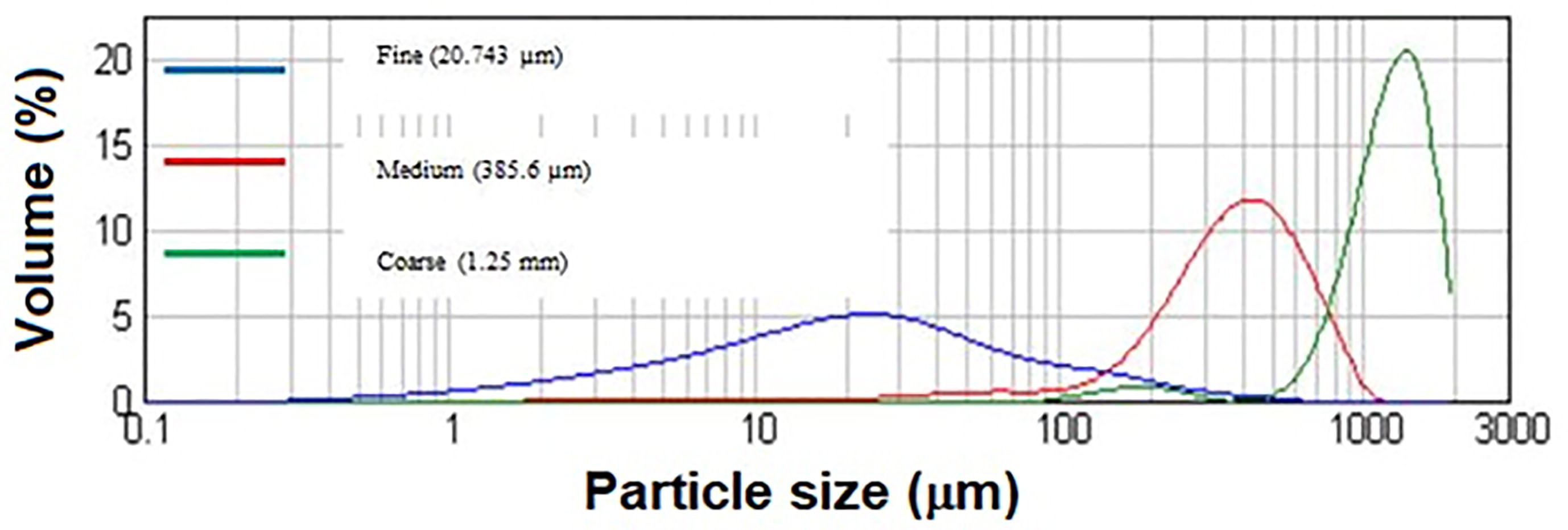

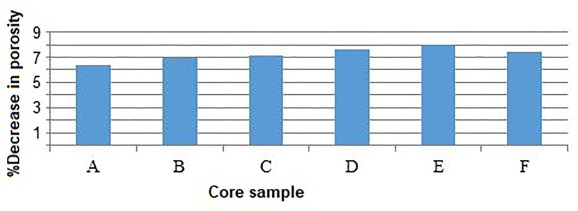

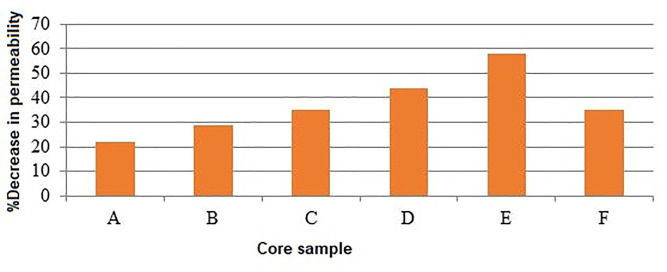

One of the most important aspects of drilling mud is the optimization of particle size of bridging agent. The bridging agent is deliberately sized to minimize the fluid loss into the reservoir and to control the permeability near the wellbore. The objective of this study is to visualize the invasion depth of drilling mud particles into the formation and to evaluate the effects of bridging agent particle size and distribution on permeability and porosity near wellbore. Calcium carbonate was used as a bridging agent. It is important to know the severity of formation damage caused by the drilling mud to attain maximum production over a long period of time. This paper describes an experimental approach to study the effects of bridging agent particles in drilling mud on formation damages. The work was performed by changing the size of bridging agent particles from fine to medium and medium to coarse. It was observed that the calcium carbonate size should be almost identical to the pore throat median size of the formation face. The minimum reduction in permeability was noticed when pore spaces were covered with bridging particles, which prevent the fluid loss into the formation.

Methodology

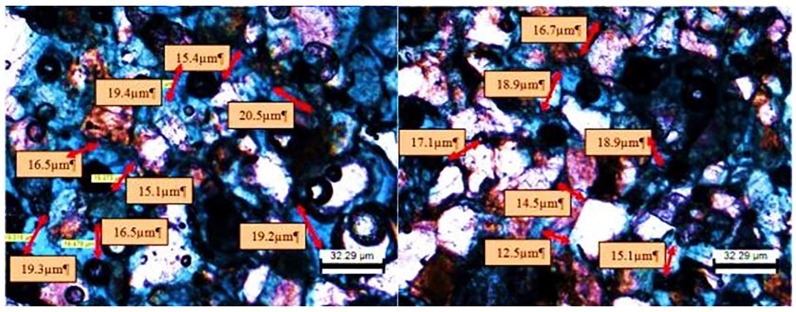

In the study, six samples of drilling mud with different sizes and distributions of calcium carbonate particles were prepared and tested. The mud was formulated using various components, as specified in Table 2. The mass of calcium carbonate was kept constant at 20 g. Core plugs were prepared from sandstone rock and flooded with the drilling mud. The permeability and porosity of the core plugs were measured before and after the flooding test. The severity of formation damage was determined based on the percentage difference. The deposition of particles in the core plugs was examined using Scanning Electron Microscopy (SEM) by observing the cross section and pore size distribution.

Impact & Benefits

Formation Protection: Properly sized bridging agents can help to seal off pore throats in the formation, preventing the invasion of drilling fluids into the formation matrix. This protection minimizes damage to the formation, including fines migration and pore plugging.

Reduced Fluid Loss: Bridging agents with an optimal particle size distribution can effectively control fluid loss into the formation. By creating a filter cake with well-distributed particles, they can reduce the permeability of the filter cake while still allowing the necessary fluid flow through the wellbore.

Improved Wellbore Stability: The use of bridging agents with appropriate particle sizes can enhance wellbore stability by preventing the erosion of formation materials and stabilizing the wellbore walls. This reduces the risk of wellbore collapse or formation damage due to unstable conditions.

Enhanced Reservoir Productivity: Minimizing formation damage near the wellbore ensures better connectivity between the reservoir and the wellbore. This can lead to improved reservoir productivity and ultimately higher production rates over the life of the well.

Market Potential

Increasing Exploration and Production Activities: The global demand for energy continues to rise, driving increased exploration and production activities in both conventional and unconventional reservoirs. As a result, there's a growing need for efficient drilling technologies to access hydrocarbon resources while minimizing formation damage.

Fokus on Enhanced Oil Recovery (EOR): With many mature oil fields, there's a shift towards EOR techniques to maximize recovery. Optimizing drilling practices, including the use of effective bridging agents, becomes crucial in EOR processes to maintain reservoir integrity and productivity.

Stringent Environmental Regulations: Environmental concerns and regulations are pushing the industry towards cleaner and more sustainable practices. Bridging agents that reduce formation damage can contribute to minimizing environmental impact by improving drilling efficiency and reducing the volume of drilling fluids required.

Technological Advancements: Ongoing research and development efforts are driving innovations in drilling fluid technology, including the optimization of particle size distribution for bridging agents. As new formulations and methodologies are developed, there's potential for market growth and adoption.