Research Success Stories

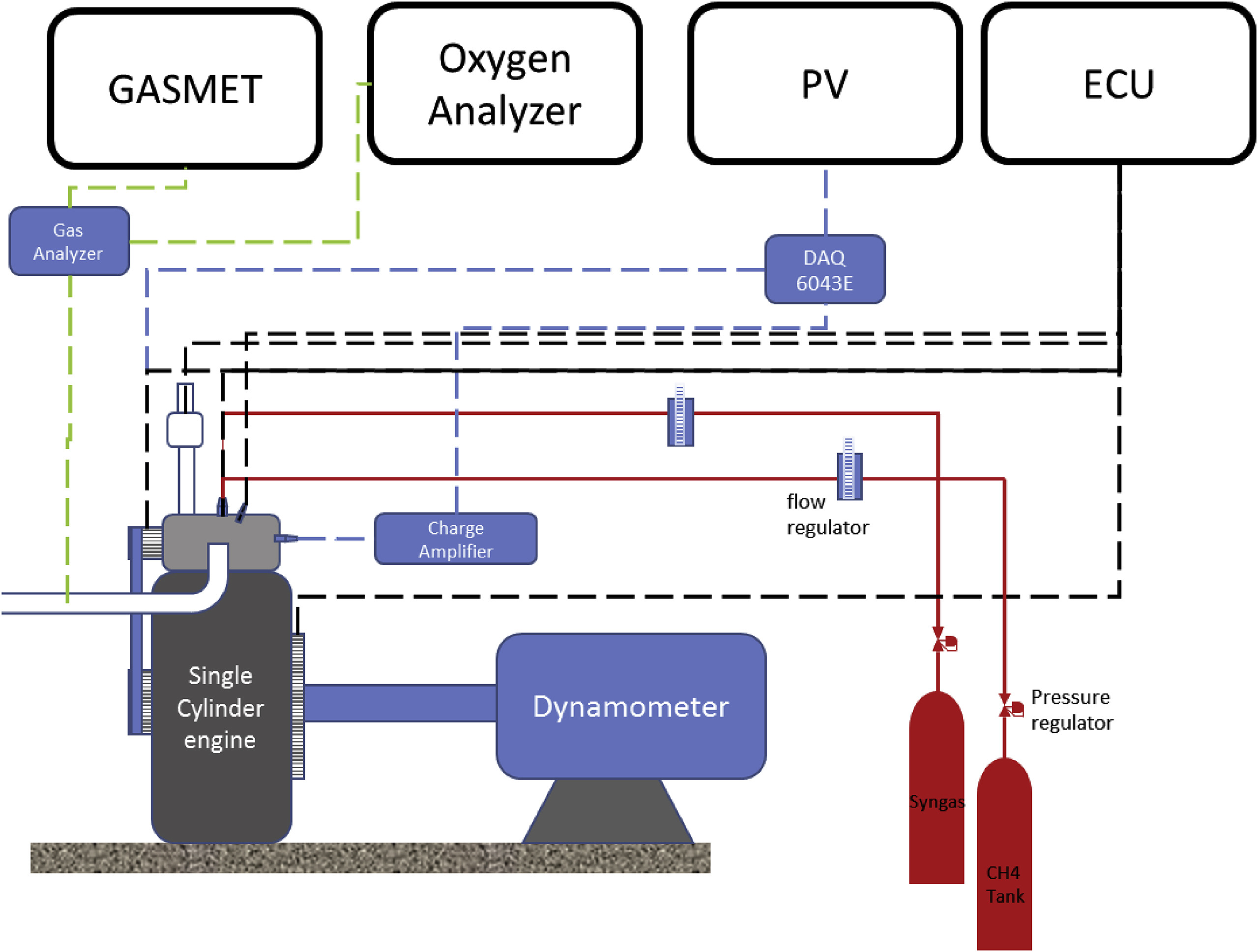

The product of gasification of solid biomass, also called syngas is believed to be good fuel for internal combustion engines in the move from the carbon based fuel to zero emission fuels. The only problem is its lower calorific value which is placed at one third of that of compressed natural gas (CNG). There are latest efforts to enhance the hydrogen rich syngas by augmenting it with methane so that the calorific value can be improved. This paper presents experimental results of the effect of the start of fuel injection timing (SOI) on the combustion characteristics, performance and emissions of a direct-injection spark-ignition engine fueled with a 20% methane augmented hydrogen rich syngas of molar ratio of 50% H2 and 50% CO composition. The engine was operated at fully open throttle and the start of fuel injection (SOI) was varied at 90, 120 and 180° before top dead center (BTDC). The experiment was conducted at lean mixture conditions in the low and medium engine speed ranges (1500-2400 RPM). The spark advance was set to the minimum advance for a maximum brake torque in all the test parameters. The methane augmented hydrogen rich syngas was observed to perform well over wide range of operation with SOI = 180°CA BTDC. However, SOI = 120°CA BTDC performed well at lower speeds recording improved performance and emissions. Limitation of operable load was observed for both SOI = 120°CA BTDC and 90°CA BTDC due to an insufficient time for complete injection of fuel at lower relative air-fuel ratio (λ) with higher speeds.

Posted on: September 2017

Authored: Shaharin Anwar Sulaiman

Development of erosion-corrosion mechanisms for the study of steel surface behavior in a sand slurry

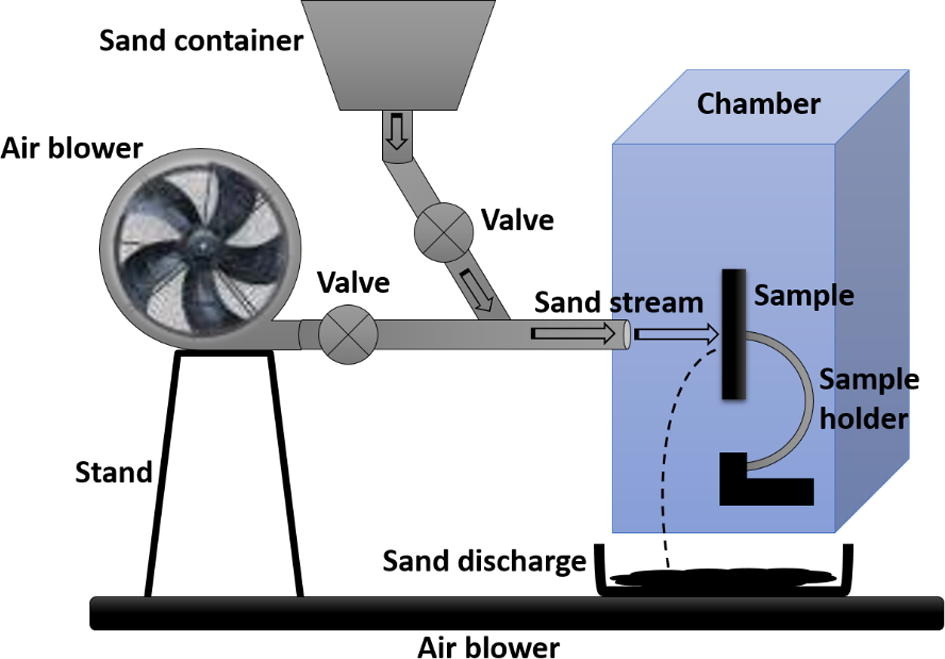

In this study, dry sand impact and linear polarization resistance (LPR) monitoring techniques were used to study the detrimental effects of the sand size on surface morphology of the mild steel. An electrochemical mechanism was developed to measure the resistance of the metal coupons rotating in a slurry of 4wt% NaCl and 5wt% sand. Scanning probe microscopy (SPM) and hardness testing of the eroded coupons were conducted to elaborate their surface topography. In-depth analysis revealed that not only the larger particles but smaller particles as well caused significant erosion-corrosion of the steel coupons. It was noticed that hardness and density of the erodent particles were reasonably high to induce the plastic deformation and micro-structures at the metal surface. The LPR measurements revealed high coupon resistance in the fine sand slurry than in the coarse sand slurry. The localized corrosion and erosion-corrosion attacks on the metal surface were also supplemented with the stirring rate and the presence of NaCl in the solution. The corrosion rate was sharply increased with an increase in stirring rate above 500rpm.

Posted on: August 2017

Authored: Shaharin Anwar Sulaiman

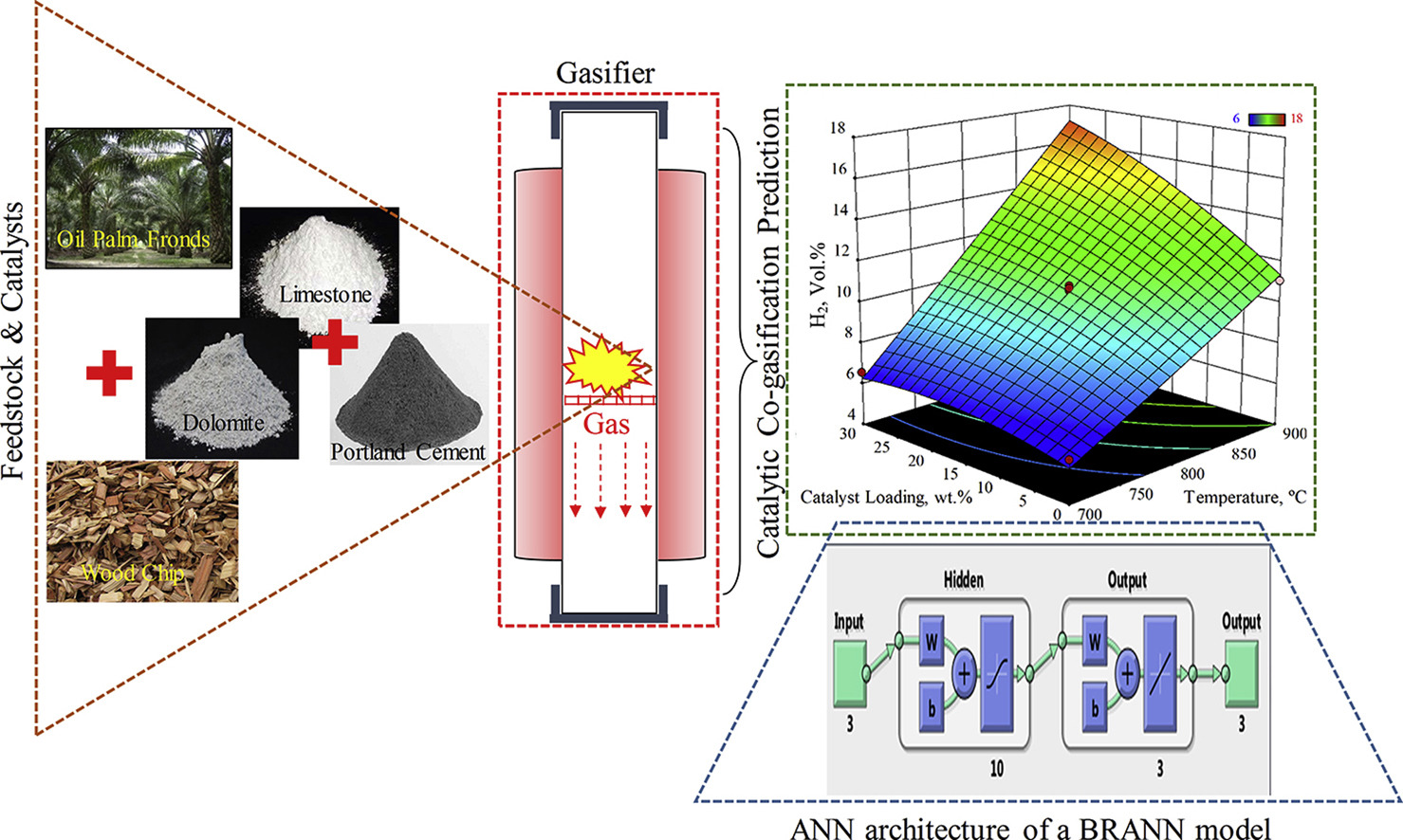

Syngas production from biomass gasification is a potentially sustainable and alternative means of conventional fuels. The current challenges for biomass gasification process are biomass storage and tar contamination in syngas. Co-gasification of two biomass and use of mineral catalysts as tar reformer in downdraft gasifier is addressed the issues. The optimized and parametric study of key parameters such as temperature, biomass blending ratio, and catalyst loading were made using Response Surface Methodology (RSM) and Artificial Neural Network (ANN) on tar reduction and syngas. The maximum H2 was produced when Portland cement used as catalyst at optimum conditions, temperature of 900 °C, catalyst-loading of 30%, and biomass blending-ratio of W52:OPF48. Higher CO was yielded from dolomite catalyst and lowest tar content obtained from limestone catalyst. Both RSM and ANN are satisfactory to validate and predict the response for each type of catalytic co-gasification of two biomass for clean syngas production.

Posted on: August 2021

Authored: Shaharin Anwar Sulaiman

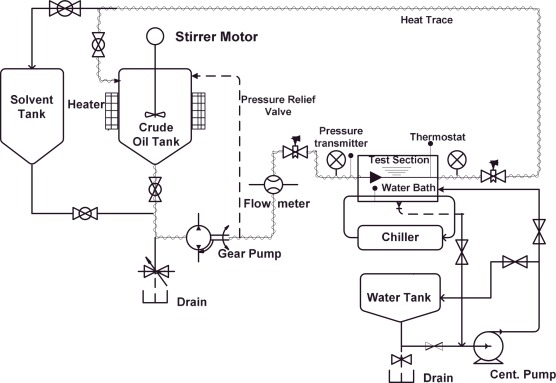

Waxy crude oil solidifies when exposed to certain range of low seabed temperature. In this condition, predicting an accurate restart pressure in the pipeline has remained to be a challenge. Recent researches highlighted that the presence of gas voids in the gel has an impact on the gelled crude oil morphology and consequently on the restarting pressure. The gelling due to cooling of the oil is complex and not well understood. This study is aimed at analyzing the effects of cooling regimes on the formation of gas voids along and across the pipeline using a 3 T Magnetic Resonance Imaging (3 T-MRI) system. A flow loop rig simulating offshore oil transportation was designed and developed to produce the gel. It was found that voids were formed within gelled crude oil by 11.3% in volume. The results from the cooling regime under constant start temperature showed that the widest cooling regime resulted in a maximum voids volume in all regions in the pipe. However, reducing the cooling regime did not guarantee a decrease in volume of voids, for which lower cooling regimes occasionally resulted in a higher percentage of voids volume. For the cooling regimes under constant end temperature, in general, an increase in cooling regime resulted in a higher percentage of voids volume in the gel at lower end temperature. On the contrary, the intra-gel voids formation at higher end temperature was found to be different and a higher cooling regime did not result in a higher voids volume near pipe wall. Indeed, a higher cooling regime formed a higher percentage of voids volume around pipe core.

Posted on: December 2015

Authored: Shaharin Anwar Sulaiman

This study investigated the dry and aqueous erosion of mild steel using electrochemical and dry sand impact techniques. In dry sand impact experiments, mild steel was eroded with 45 m and 150 m sand particles. Scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX) and micro-hardness techniques were used to elaborate the surface morphology of the eroded samples. The results revealed significant change in morphology of the eroded samples. In-depth analysis showed that although the metal erosion due to larger particles was significantly higher, the fines also notably damaged the metal surface. The surface damages were appreciably reduced with decrease in impact angle of the accelerated particles. The maximum damages were observed at an impact angle of 90°. The hardness of the samples treated with 45 µm and 150 µm sand remained in the range of 88.34 to 102.31 VHN and 87.7 to 97.55 VHN, respectively. In electrochemical experiments, a triple electrode probe was added into the metal treatment process. The linear polarization resistance (LPR) measurements were performed in slurries having 5% (by weight) of sand particles. LPR of the samples treated with 45 µm and 150 µm sand slurries was calculated about 949 Ω.cm² and 809 Ω.cm², respectively.

Posted on: November 2015

Authored: Shaharin Anwar Sulaiman