Effect of fuel injection timing of hydrogen rich syngas augmented with methane in direct-injection spark-ignition engine

Author: Shaharin Anwar Sulaiman - September 2017

Abstract

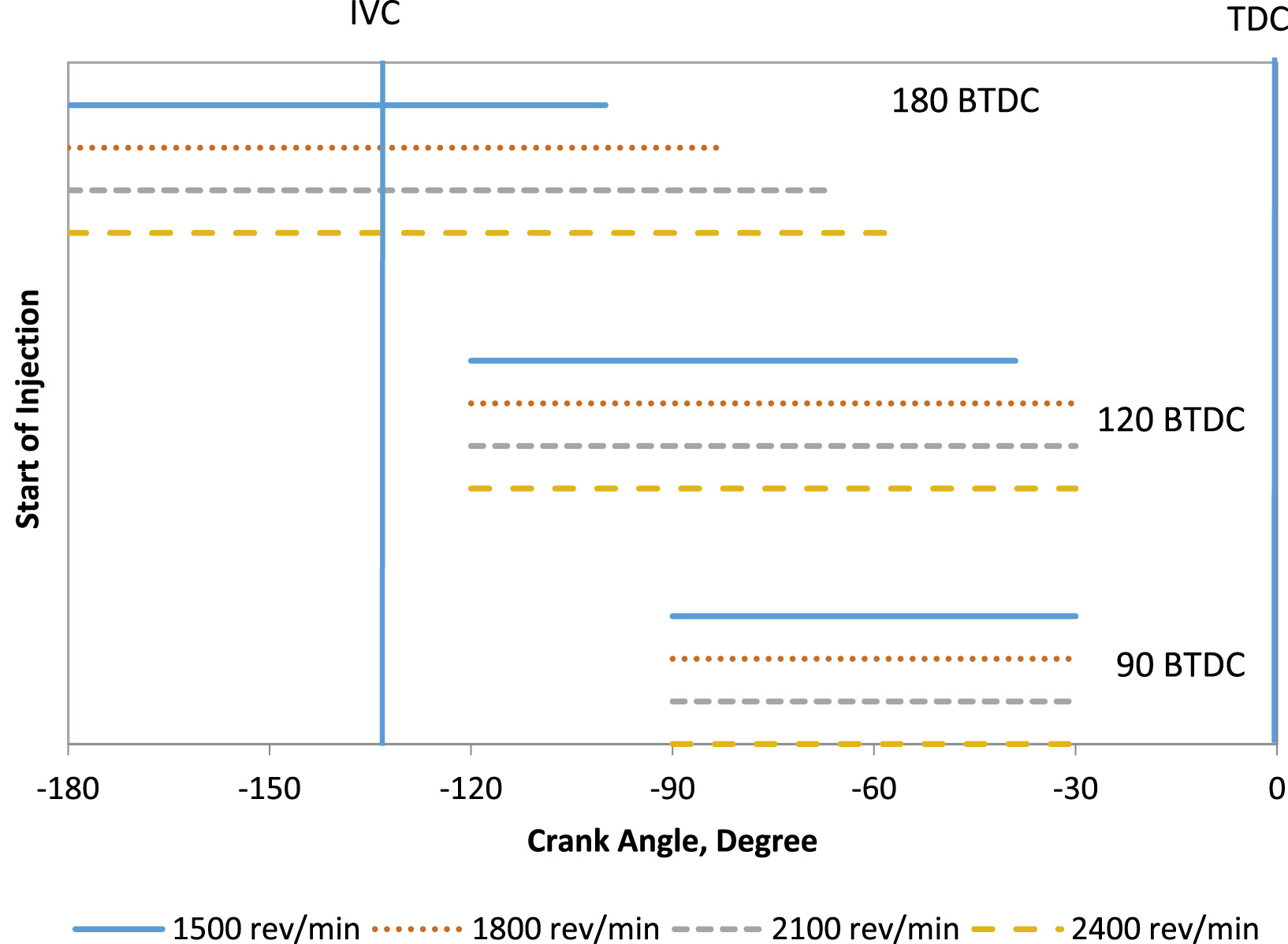

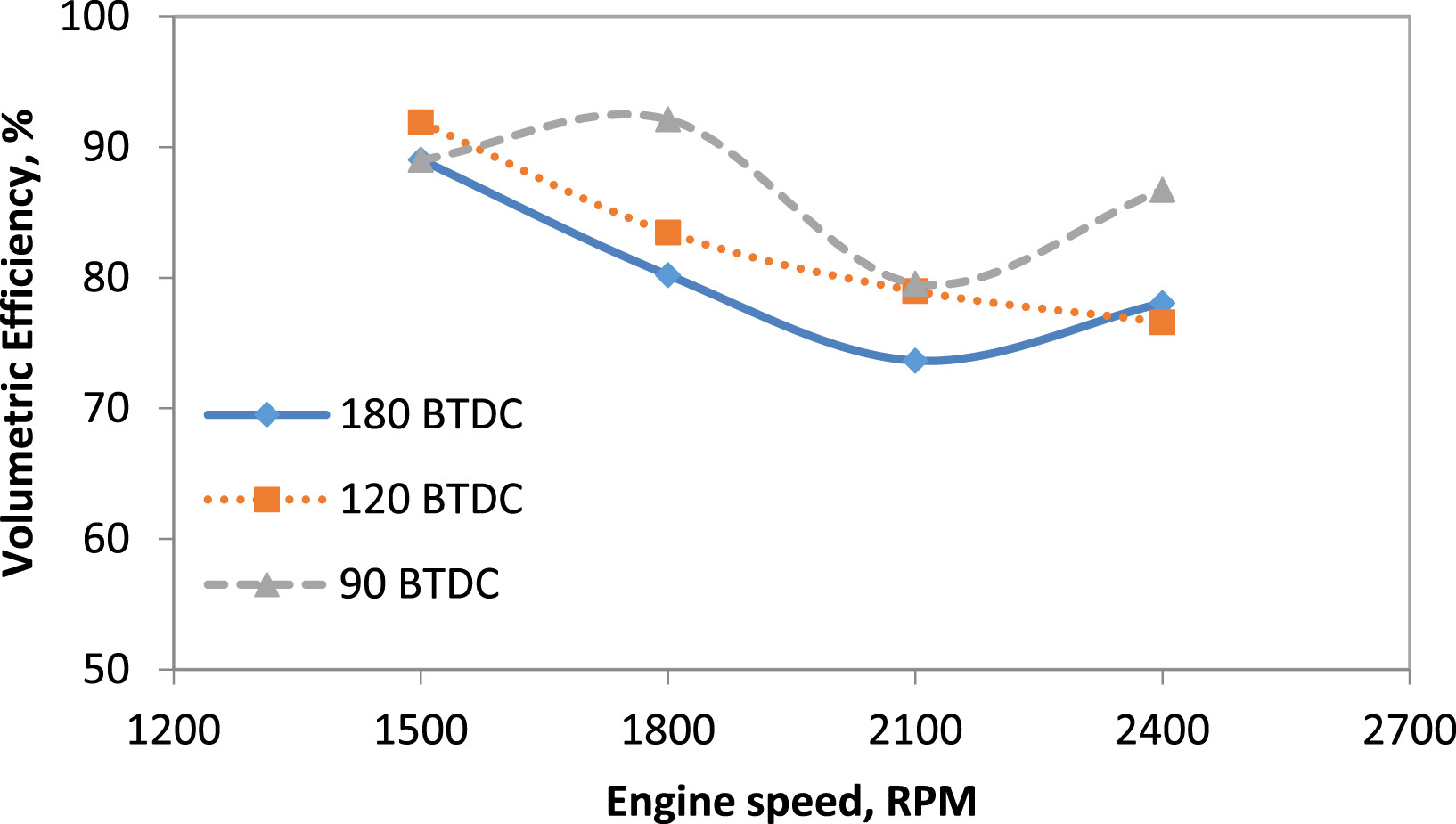

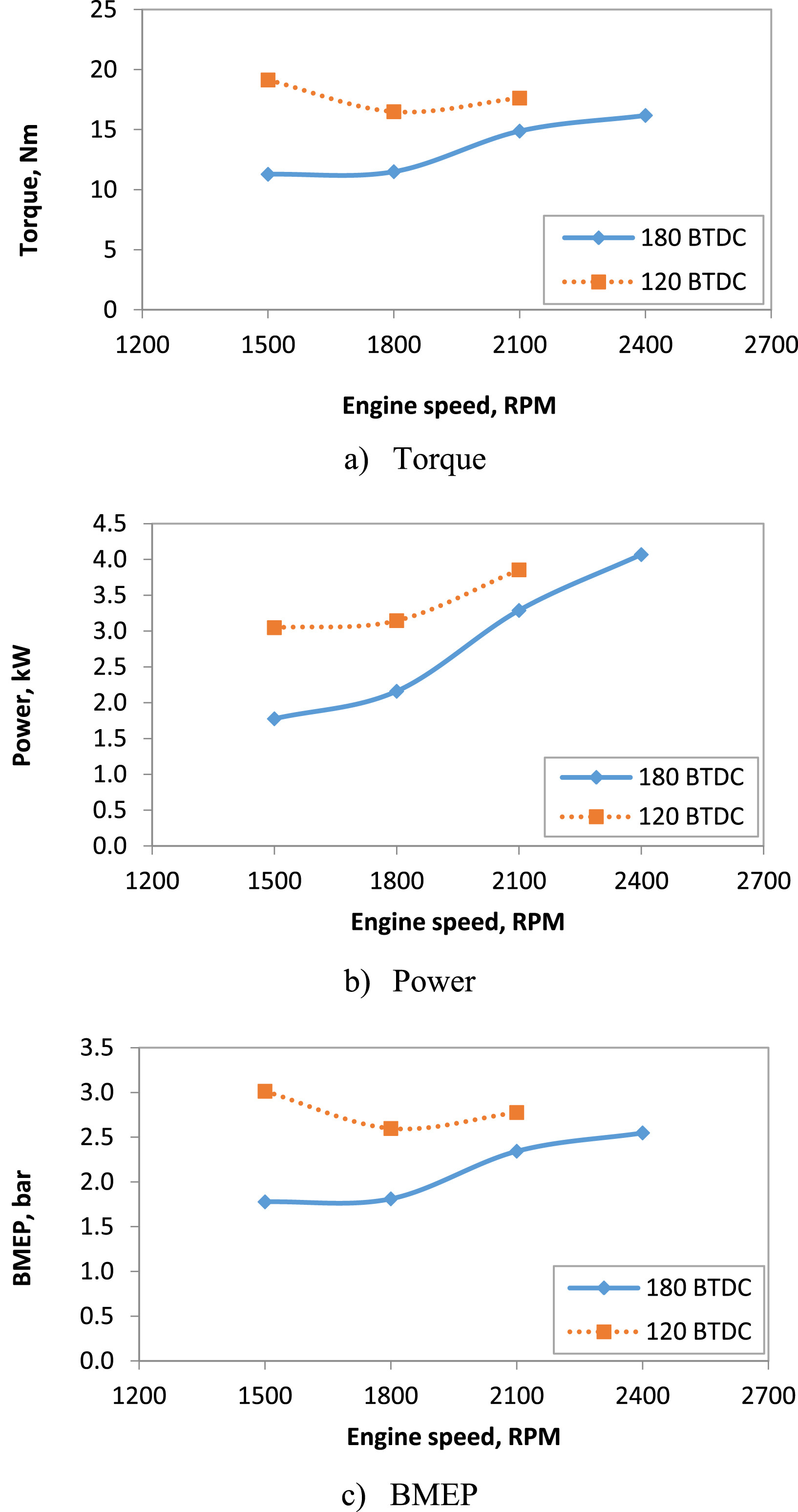

The product of gasification of solid biomass, also called syngas is believed to be good fuel for internal combustion engines in the move from the carbon based fuel to zero emission fuels. The only problem is its lower calorific value which is placed at one third of that of compressed natural gas (CNG). There are latest efforts to enhance the hydrogen rich syngas by augmenting it with methane so that the calorific value can be improved. This paper presents experimental results of the effect of the start of fuel injection timing (SOI) on the combustion characteristics, performance and emissions of a direct-injection spark-ignition engine fueled with a 20% methane augmented hydrogen rich syngas of molar ratio of 50% H2 and 50% CO composition. The engine was operated at fully open throttle and the start of fuel injection (SOI) was varied at 90, 120 and 180° before top dead center (BTDC). The experiment was conducted at lean mixture conditions in the low and medium engine speed ranges (1500-2400 RPM). The spark advance was set to the minimum advance for a maximum brake torque in all the test parameters. The methane augmented hydrogen rich syngas was observed to perform well over wide range of operation with SOI = 180°CA BTDC. However, SOI = 120°CA BTDC performed well at lower speeds recording improved performance and emissions. Limitation of operable load was observed for both SOI = 120°CA BTDC and 90°CA BTDC due to an insufficient time for complete injection of fuel at lower relative air-fuel ratio (λ) with higher speeds.

Methodology

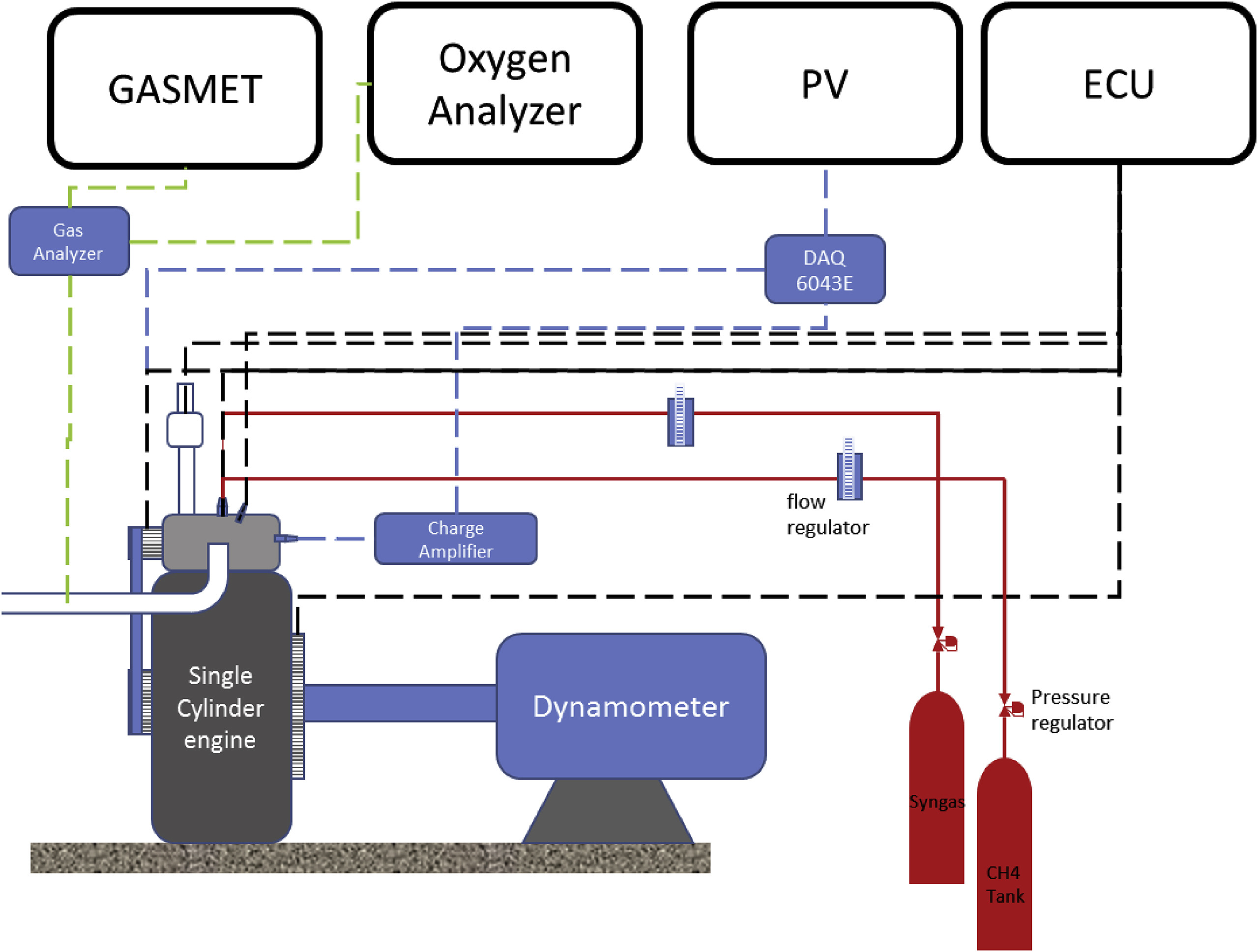

The workbench used is a four-stroke, single-cylinder, DI SI research engine. The engine has compression ratio of 14:1 with a displacement volume of the engine is 399.25m³ (cylinder bore of 76 mm and stroke 88 mm) and two inlet and two outlet valves, the schematic diagram shown in Fig. 1. The inlet valve opening and closing are 12°CA before top dead center (BTDC) and 48°CA after top dead center (ATDC), respectively while the exhaust valve counterparts at 45°CA before bottom dead center (BBDC) and 10°CA ATDC. The rated power of the engine is 13 kW at 5000 rpm. The engine is coupled with an eddy current type electric dynamometer. Engine parameters such as the start of the injection (SOI), ignition timing (the minimum ignition advance for a maximum brake torque) and air-fuel ratio are controlled by Engine Control Unit (ECU) connected to a remote interface installed in a computer programmed to dictate the engine operation with pre-loaded engine maps of parameters. With the usage of interface software, it is possible to manually alter the engine operating conditions. The interface software can also be used to measure the engine operating parameters by using the various sensors connected to the ECU. The engine parameters that can be controlled from the computer are the SOI and the injection duration, the spark timing and the air fuel ratio. The engine is also equipped with further sensors like induction air temperature, exhaust air temperature, engine oil temperature, engine coolant temperature, room temperature, relative humidity and room atmospheric pressure.

Impact & Benefits

Improved Combustion Efficiency: Optimizing the fuel injection timing can enhance the combustion process, leading to more efficient utilization of the fuel mixture. This can result in improved engine performance and fuel economy.

Reduced Emissions: Proper timing of fuel injection can help achieve more complete combustion, which can reduce the formation of harmful emissions such as carbon monoxide (CO), unburned hydrocarbons (HC), and nitrogen oxides (NOx). Hydrogen-rich syngas has the potential to produce fewer emissions compared to conventional gasoline or diesel fuel.

Enhanced Power Output: Adjusting the injection timing can influence the peak pressure and torque characteristics of the engine, potentially leading to increased power output without compromising efficiency.

Stability and Durability: Optimal injection timing can contribute to the stability and durability of the engine by minimizing the likelihood of knocking or misfiring, which can cause damage over time.

Market Potential

Environmental Regulations: Stringent emission regulations worldwide drive the demand for cleaner-burning fuels and more efficient engine technologies. Hydrogen-rich syngas augmented with methane offers the potential for reduced emissions compared to conventional gasoline or diesel fuels, aligning with regulatory requirements.

Energy Transition: The global shift towards renewable energy sources and decarbonization efforts accelerates the adoption of alternative fuels like hydrogen and syngas derived from renewable sources. Direct-injection spark-ignition engines optimized for hydrogen-rich syngas present a viable option for transitioning away from fossil fuels.

Technological Advancements: Ongoing advancements in engine design, fuel injection systems, and control algorithms enable the efficient utilization of hydrogen-rich syngas augmented with methane. As these technologies mature, they become more accessible and cost-effective for widespread deployment.

Energy Security: Diversifying the fuel supply with alternative sources such as hydrogen and syngas enhances energy security by reducing reliance on finite fossil fuel reserves and mitigating geopolitical risks associated with traditional fuel imports.