Effects of cooling regime on the formation of voids in statically cooled waxy crude oil

Author: Shaharin Anwar Sulaiman - December 2015

Abstract

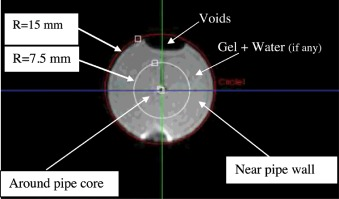

Waxy crude oil solidifies when exposed to certain range of low seabed temperature. In this condition, predicting an accurate restart pressure in the pipeline has remained to be a challenge. Recent researches highlighted that the presence of gas voids in the gel has an impact on the gelled crude oil morphology and consequently on the restarting pressure. The gelling due to cooling of the oil is complex and not well understood. This study is aimed at analyzing the effects of cooling regimes on the formation of gas voids along and across the pipeline using a 3 T Magnetic Resonance Imaging (3 T-MRI) system. A flow loop rig simulating offshore oil transportation was designed and developed to produce the gel. It was found that voids were formed within gelled crude oil by 11.3% in volume. The results from the cooling regime under constant start temperature showed that the widest cooling regime resulted in a maximum voids volume in all regions in the pipe. However, reducing the cooling regime did not guarantee a decrease in volume of voids, for which lower cooling regimes occasionally resulted in a higher percentage of voids volume. For the cooling regimes under constant end temperature, in general, an increase in cooling regime resulted in a higher percentage of voids volume in the gel at lower end temperature. On the contrary, the intra-gel voids formation at higher end temperature was found to be different and a higher cooling regime did not result in a higher voids volume near pipe wall. Indeed, a higher cooling regime formed a higher percentage of voids volume around pipe core.

Methodology

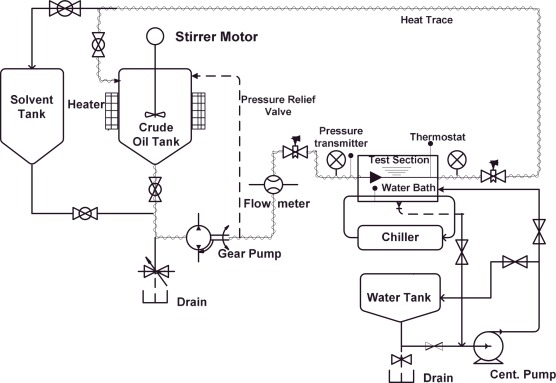

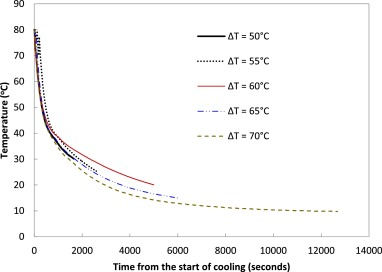

In the present study, cooling regime refers to temperature difference between the start and end temperatures of the sample. The cooling regimes were measured by varying either the start temperature or the end temperature at a time while maintaining the other one constant. The first case was performed by keeping the start temperatures constant so that the MRI scans were made at different end temperatures, which hereinafter referred to as cooling regime under constant start temperature. The second case of experiments was done by keeping the end temperatures of the sample constant for all samples cooled from variable start temperatures, which hereinafter named as cooling regime under constant end temperature. The start temperatures were kept well above the wax appearance temperature of the waxy crude oil to erase any thermal and shear histories encountered earlier, which was made by circulating the sample in the closed loop. The circulation was made for about 5-10 min prior to each experiment to standardize the flow and to make sure that the test fluid was homogeneous and in liquid-phase at higher temperature simulating a liquid waxy crude oil coming from the well/reservoir. Following standardization of the flow the gear pump was switched off to simulate statically cooled waxy crude oil. Waxy crude oil then underwent through static cooling from a start temperature to an end temperature below the pour point. Table 2 shows experimental details when the start temperatures were kept constant for all tests. The gels formed below the pour point temperature were scanned from 30°C to 10°C end temperatures, with 5°C increment between each experiment. Fig. 2 shows temperature profiles and cooling regimes under constant start temperature during the experimental tests prior to the MRI scanning.

Impact & Benefits

Preventing Pipeline Blockages: Waxy crude oils contain paraffin wax, which can solidify and form deposits when the oil is cooled. These deposits can accumulate in pipelines, causing blockages and flow restrictions, which can disrupt oil transportation and increase operational costs. Understanding how different cooling regimes affect the formation of voids (or spaces) within the solidified wax matrix can help in designing strategies to mitigate or prevent pipeline blockages.

Optimizing Production Processes: By understanding the relationship between cooling regimes and void formation, oil producers can optimize their production processes to minimize wax deposition during crude oil storage and transportation. This optimization can lead to increased operational efficiency and reduced downtime associated with pipeline maintenance and cleaning.

Enhancing Crude Oil Quality: The presence of voids within solid wax structures can affect the overall quality of crude oil. For example, voids may trap impurities or water, leading to issues such as corrosion or degradation of the oil quality. By controlling void formation through appropriate cooling regimes, producers can maintain the quality of crude oil and ensure compliance with industry standards and specifications.

Reducing Environemental Impact: Pipeline blockages caused by wax deposition can have environmental consequences, such as oil spills and habitat disruption. By implementing effective cooling regimes to minimize void formation and wax deposition, companies can reduce the risk of environmental incidents associated with oil transportation and storage.

Market Potential

Industry Demand: The oil and gas industry is always seeking ways to optimize production processes, minimize operational costs, and mitigate risks associated with transportation and storage. Understanding how cooling regimes affect void formation in waxy crude oil directly addresses these concerns, making it a topic of high interest and demand within the industry.

Global Reach: The market potential extends globally, as waxy crude oils are produced and transported in various regions around the world. Any advancements or technologies developed to better manage wax deposition and void formation can find application in different geographical locations, providing opportunities for market penetration on a global scale.

Regulatory Compliance: There are often stringent regulations governing the transportation and storage of crude oil, with specific requirements regarding environmental protection, safety, and quality standards. Technologies that address wax deposition and void formation can help companies comply with these regulations, creating a market niche driven by regulatory requirements.

Cost Savings: The potential for cost savings associated with preventing pipeline blockages, reducing maintenance downtime, and optimizing production processes can be a significant driver for investment in research and technologies related to cooling regimes and void formation in waxy crude oil. Companies are willing to invest in solutions that offer tangible cost benefits and improve their bottom line.