Electrochemical and Dry Sand Impact Erosion Studies on Carbon Steel

Author: Shaharin Anwar Sulaiman - November 2015

Abstract

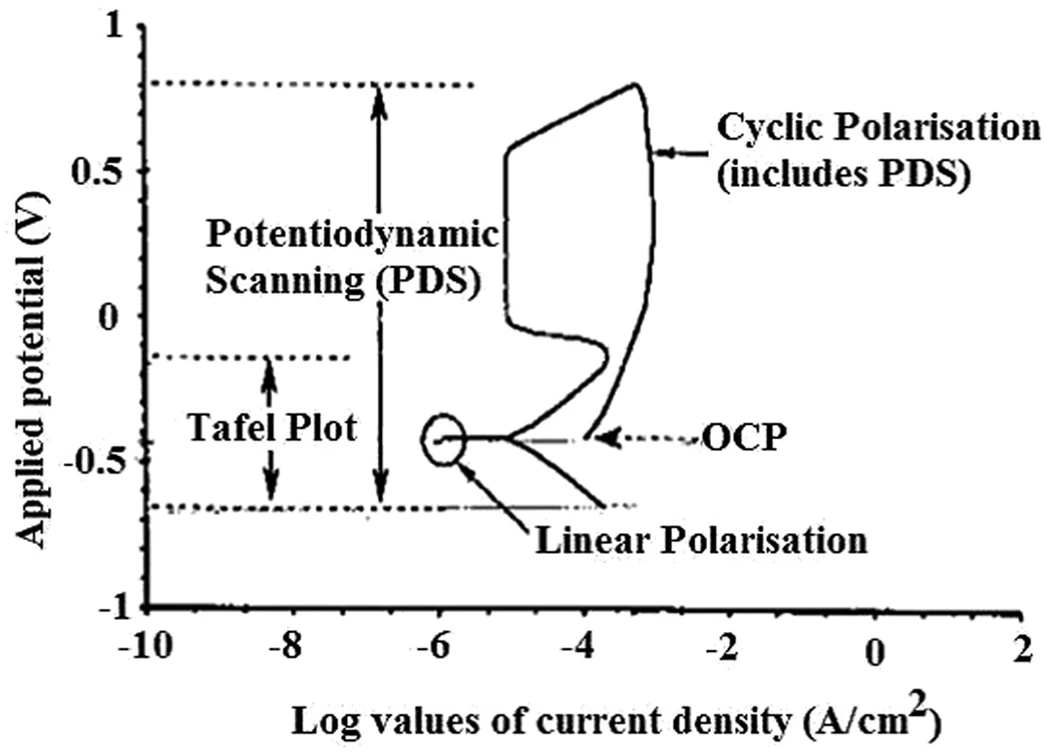

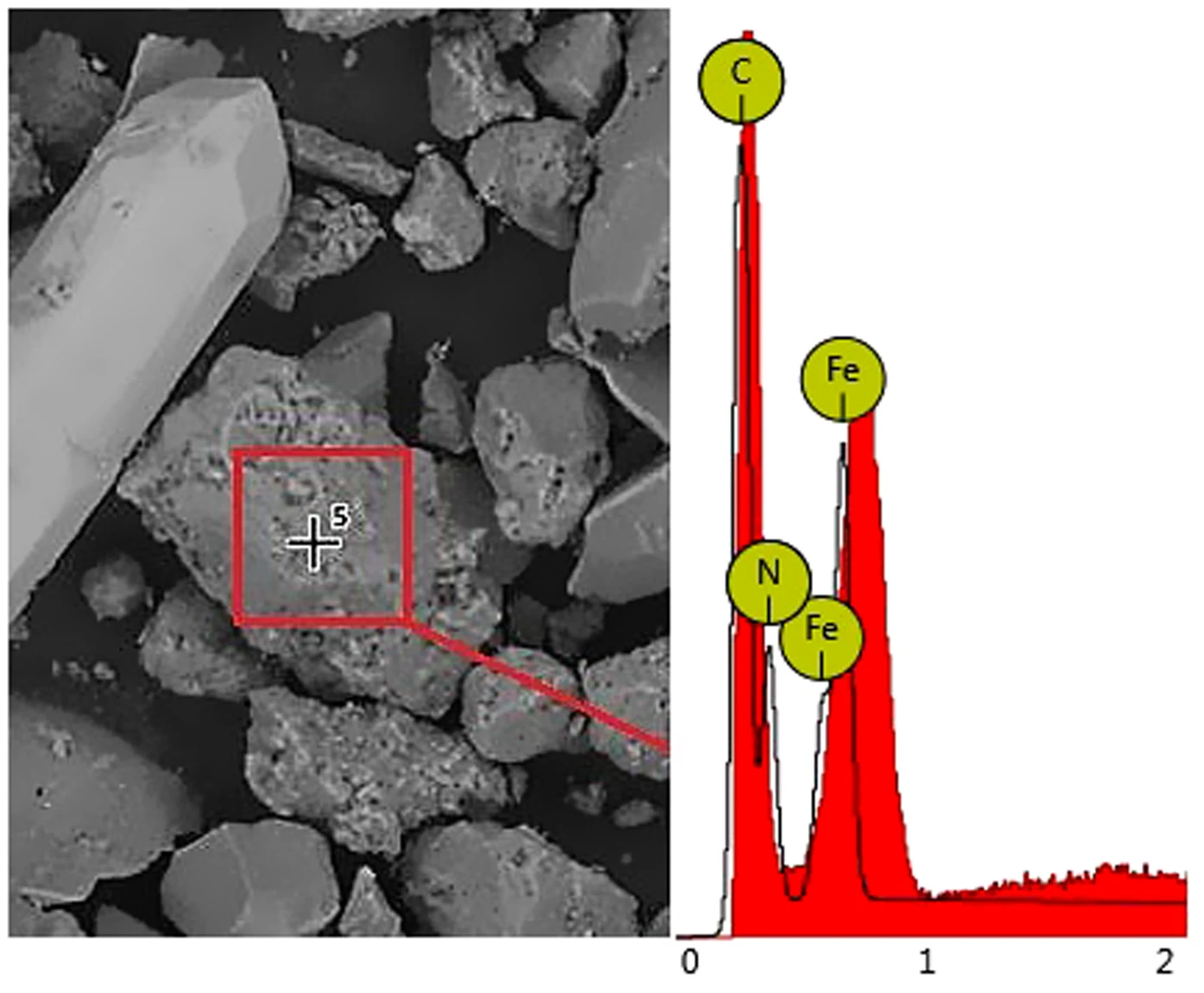

This study investigated the dry and aqueous erosion of mild steel using electrochemical and dry sand impact techniques. In dry sand impact experiments, mild steel was eroded with 45 m and 150 m sand particles. Scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX) and micro-hardness techniques were used to elaborate the surface morphology of the eroded samples. The results revealed significant change in morphology of the eroded samples. In-depth analysis showed that although the metal erosion due to larger particles was significantly higher, the fines also notably damaged the metal surface. The surface damages were appreciably reduced with decrease in impact angle of the accelerated particles. The maximum damages were observed at an impact angle of 90°. The hardness of the samples treated with 45 µm and 150 µm sand remained in the range of 88.34 to 102.31 VHN and 87.7 to 97.55 VHN, respectively. In electrochemical experiments, a triple electrode probe was added into the metal treatment process. The linear polarization resistance (LPR) measurements were performed in slurries having 5% (by weight) of sand particles. LPR of the samples treated with 45 µm and 150 µm sand slurries was calculated about 949 Ω.cm² and 809 Ω.cm², respectively.

Methodology

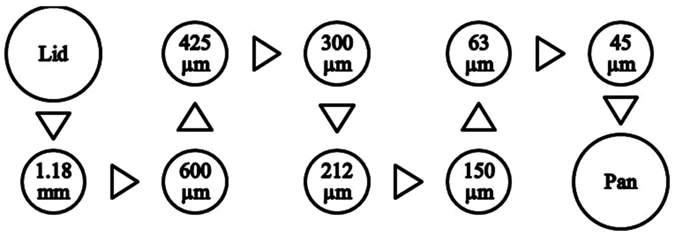

Dry sieving method was used to classify the size of the sand particles. These analyses were performed by using a set of sieves with gradually decreasing screen size. Schematic of the arrangement of the sieves used for dry sand sieving is shown in Fig. 2. The dried sand was passed through a stacked set of the sieves of the following mesh sizes: 1.18 mm, 600 µm, 425 µm, 300 µm, 212 µm, 150 µm, 63 µm and 45 µm. The formation sample was placed on the top of the mesh series and it was seeped through the screens until it faced the screen with openings smaller than the grain size. Mechanical vibrations were applied to assist the sand grains in seeping through and on to the various mesh screens. This method was used to obtain coarse and fine sand samples with average sizes of 45 µm and 150 µm, respectively.

Impact & Benefits

Understanding Degradation Mechanisms: These studies help in comprehending the mechanisms behind erosion-corrosion, which is a common mode of degradation in carbon steel. By understanding how erosion and corrosion interact at the molecular level, engineers and scientists can develop strategies to mitigate these effects.

Material Selection and Optimization: Through experimentation and analysis, researchers can identify materials and coatings that offer better resistance to erosion and corrosion in specific environments. This information is crucial for selecting the right materials for applications where carbon steel is exposed to erosive environments.

Enhancing Component Lifespan: By identifying the factors contributing to erosion and corrosion, researchers can develop strategies to extend the lifespan of carbon steel components. This could involve the development of protective coatings, surface treatments, or changes in operating conditions to minimize erosion and corrosion rates.

Cost Savings: Mitigating erosion and corrosion can result in significant cost savings by reducing the frequency of maintenance, repair, and replacement of carbon steel components. Industries such as oil and gas, marine, and power generation can benefit financially from implementing measures to combat erosion and corrosion.

Market Potential

Research and Development: There is a continuous need for research and development in industries where carbon steel components are used, such as oil and gas, automotive, aerospace, power generation, and marine sectors. As industries strive for higher efficiency, longer component lifespan, and reduced maintenance costs, there is a growing demand for studies that can provide insights into erosion-corrosion mechanisms and offer solutions for mitigating these issues.

Product Development and Innovation: Manufacturers of protective coatings, surface treatments, and erosion-resistant materials can leverage the findings from erosion studies to develop innovative products that meet the evolving needs of various industries. This includes the development of advanced coatings with enhanced erosion and corrosion resistance, as well as the optimization of manufacturing processes to improve product performance and durability.

Consulting and Services: Consulting firms and service providers specializing in materials science, corrosion engineering, and asset integrity management can offer expertise in conducting erosion studies, analyzing data, and providing recommendations for mitigating erosion-corrosion issues. As industries seek to optimize their operations and minimize downtime, there is a growing demand for consulting services that can help identify potential risks and develop proactive maintenance strategies.

Regulatory Compliance: In industries where safety and environmental regulations are stringent, such as the oil and gas sector, companies are required to demonstrate compliance with regulatory standards related to asset integrity and environmental protection. Erosion studies can help companies assess the performance of their assets, identify areas of concern, and ensure compliance with regulatory requirements, thus driving demand for specialized testing and analysis services.