Research Success Stories

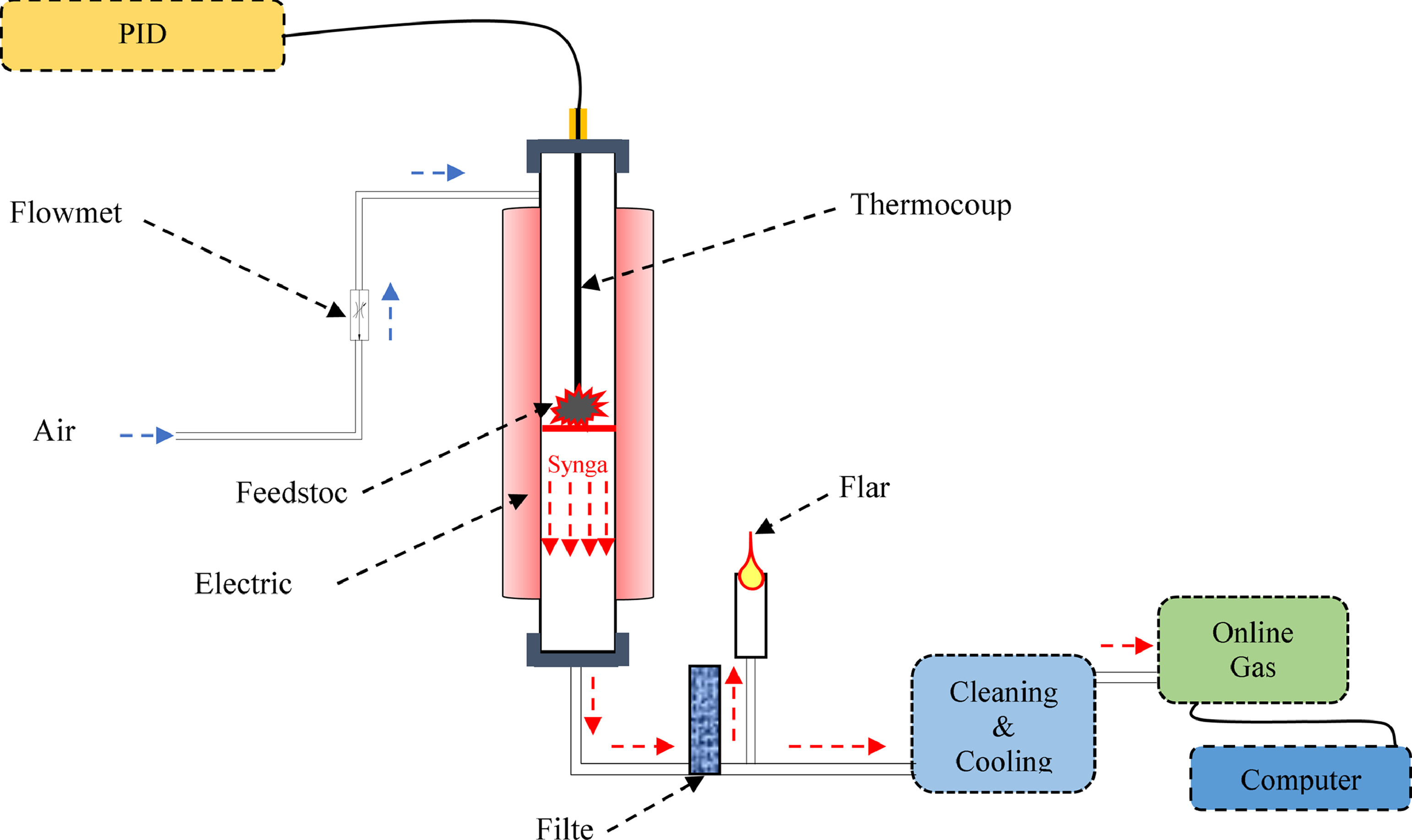

The air gasification of palm waste specifically palm kernel shell has been performed in the fixed bed gasifier using coal bottom ash as a potential catalyst. Effect of the process variables (temperature, catalyst loading, and airflow rate) has been investigated on the product gas composition. The design of experiments was accomplished using the Design Expert v11® with a Central Composite Design approach. Moreover, the parametric study and optimization of the entire process have been carried out using Response Surface Methodology within the specific range of variables. The results suggested that the temperature has been found as the most influencing parameter for increment of H2 and CO production. Whereas, airflow rate was more sensitive for CH4 and CO2 production. Catalyst loading was found very effective for the amplified amount of H2 and CO production and the reduction in the amounts of CO2 and CH4, caused by the catalytic activity of coal bottom ash (CBA). Optimized parameters are found to be the temperature of 850 °C, catalyst loading of 14.50 wt%, and airflow rate of 2.50 L/min, which predicted the composition for H2 of 31.38 vol%, CO of 26.44 vol%, CH4 of 15.67 vol%, and CO2 of 25.59 vol%.

Posted on: January 2020

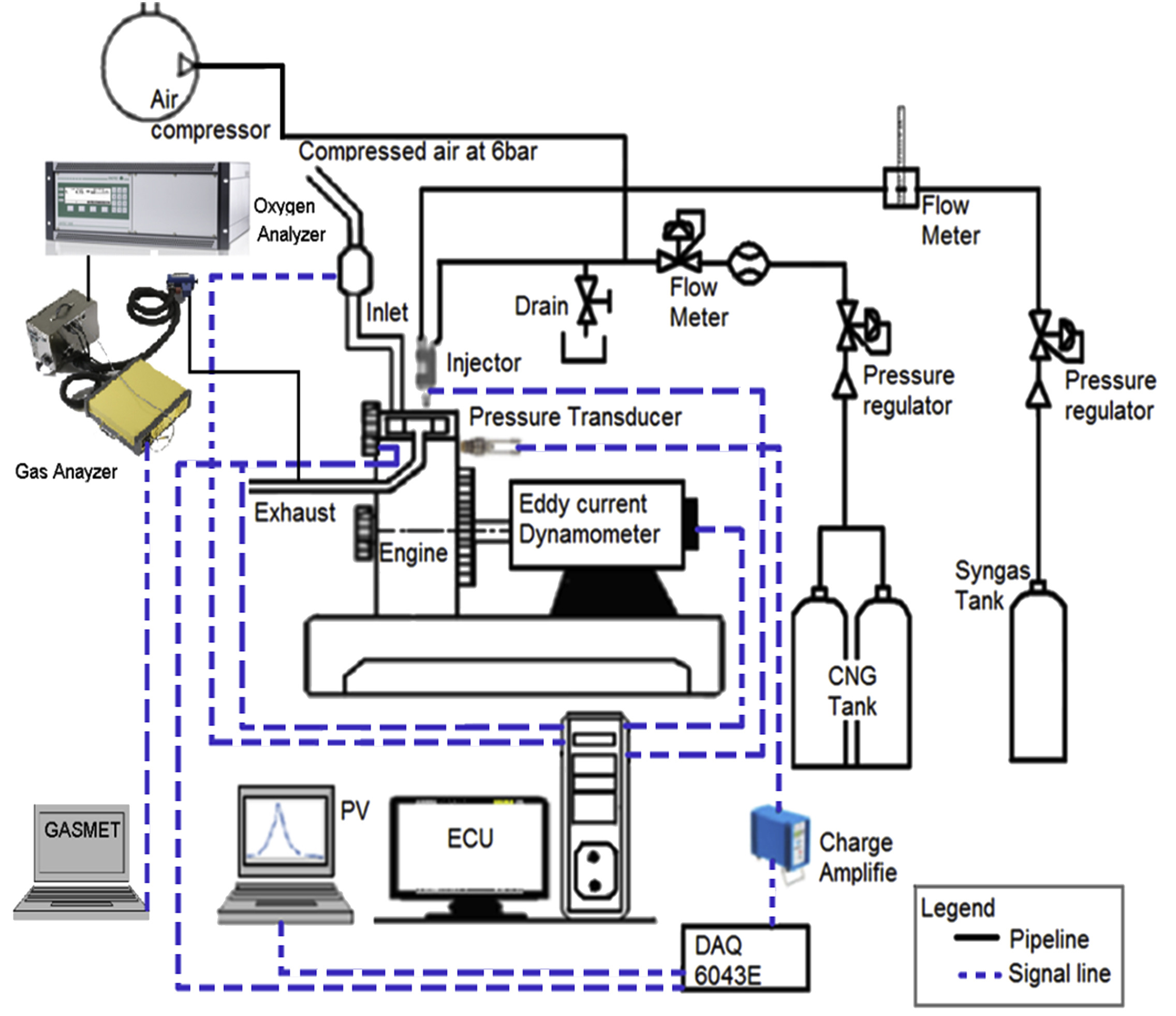

Authored: Shaharin Anwar Sulaiman

The combustion, performance, and emissions of syngas (H2/CO) in a four-stroke, direct-injection, spark-ignition engine were experimentally investigated. The engine was operated at various speeds, ranging from 1500 to 2400 rev/min, with the throttle being held in the wide-open position. The start of fuel injection was fixed at 180° before the top dead center, and the ignition advance was set at the maximal brake torque. The air/fuel ratio was varied from the technically possible lowest excess air ratio (λ) to lean operation limits. The results indicated that a wider air/fuel operating ratio is possible with syngas with a very low coefficient of variation. The syngas produced a higher in-cylinder peak pressure and heat-release rate peak and faster combustion than for CNG. However, CNG produced a higher brake thermal efficiency (BTE) and lower brake specific fuel consumption (BSFC). The BTE and BSFC of the syngas were on par to those of CNG at higher speeds. For the syngas, the total hydrocarbon emission was negligible at all load conditions, and the carbon monoxide emission was negligible at higher loads and increased under lower load conditions. However, the emission of nitrogen oxides was higher at higher loads with syngas.

Posted on: October 2014

Authored: Shaharin Anwar Sulaiman

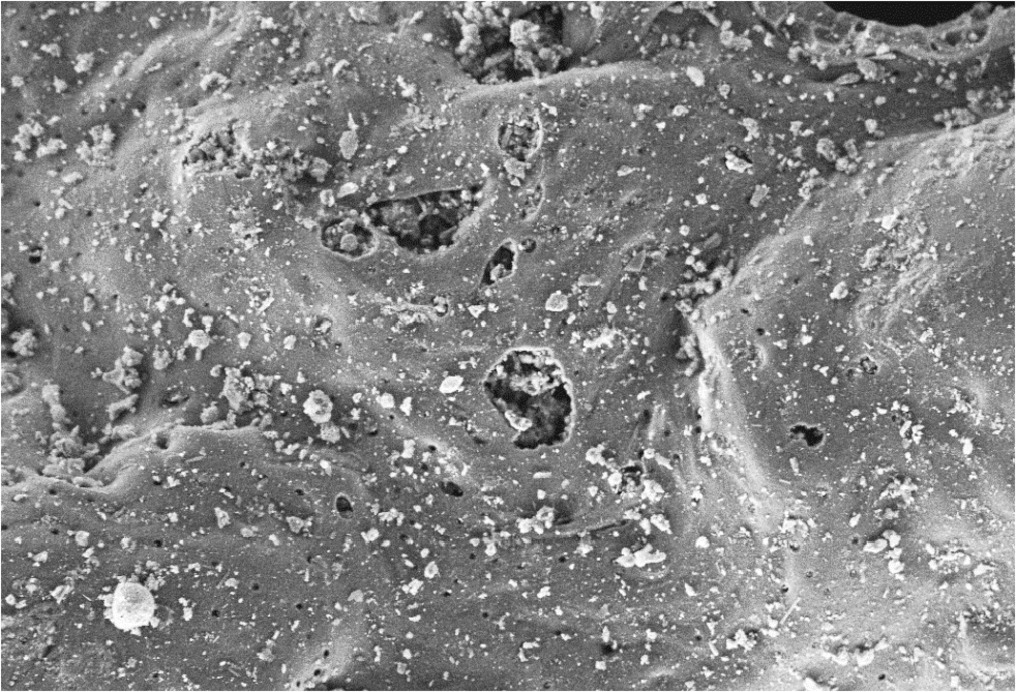

The air gasification of Palm Kernel Shells (PKS) using coal bottom ash (CBA) as a catalyst has been performed in a fixed-bed gasifier. The impact of three process parameters, namely, temperature (575-775 °C), air flowrate (1.5-45 litter/min) and catalyst loading (0-30 wt.%) has been investigated on the product gas yield. The composition of the H2 product is computed to be a maximum of 28 vol.% at 875 °C. The air flowrate has a direct relation with H2 production. The catalysts used have demonstrated a positive impact on the carbon conversion efficiency, showing the increase in carbon-containing gases in the product gas due to the increases in gas yield. A Non-linear Autoregressive Network with exogenous inputs (NARX) neural network has been used to predict the gaseous flowrate dynamically in order to improve gasification performance. The predicted results from the NARX network demonstrate good agreement with the experimental study with R2 ≥ 0.99.

Posted on: November 2020

Authored: Shaharin Anwar Sulaiman

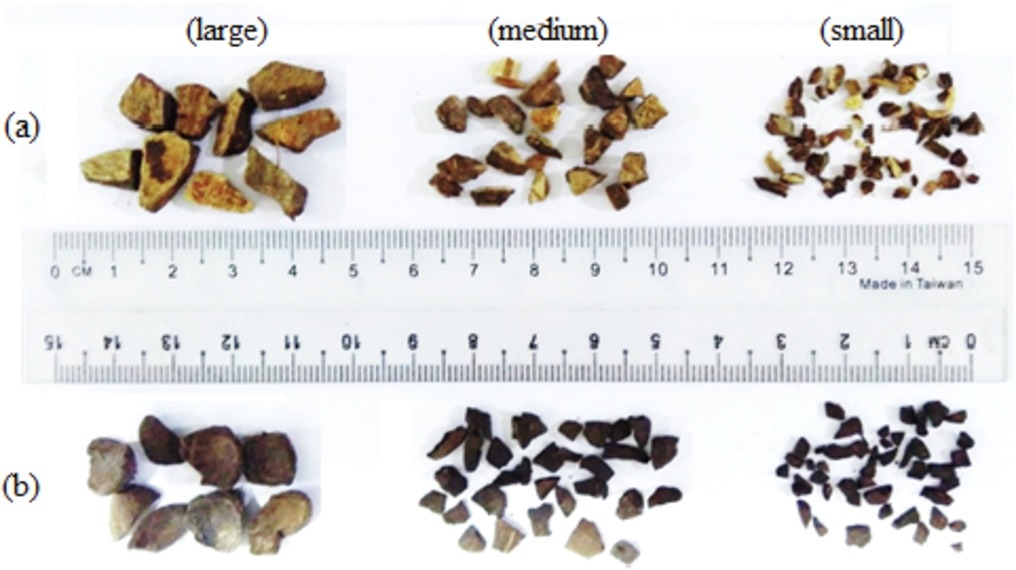

Gasification of coconut shell (CS) and palm kernel shell (PKS) is conducted in a batch type downdraft fixed-bed reactor to evaluate the effect of particle size (1-3 mm, 4-7 mm, and 8-11 mm) and temperature (700, 800, and 900 °C) on gas composition and gasification performance. The response surface methodology integrated variance-optimal design is used to identify the optimum condition for gasification. Gas composition, which is measured using the biomass particle size of 1-11 mm at 700-900 °C, are 8.20-14.6 vol% (H2), 13.0-17.4 vol% (CO), 14.7-16.7 vol% (CO2), and 2.82-4.23 vol% (CH4) for CS and 7.01-13.3 vol% (H2), 13.3-17.8 vol% (CO), 14.9-17.1 vol% (CO2), and 2.39-3.90 vol% (CH4) for PKS. At similar conditions, the syngas higher heating value, dry gas yield, carbon conversion efficiency, and cold gas efficiency are 4.01-5.39 MJ/Nm3, 1.50-1.95 Nm3/kg, 52.2-75.9%, and 30.9-56.4% for CS, respectively, and 3.82-5.09 MJ/Nm3, 1.48-1.92 Nm3/kg, 59.0-81.5%, and 33.0-57.1% for PKS, respectively. Results reveal that temperature has a greater role than particle size in influencing the gasification reaction rate.

Posted on: May 2019

Authored: Shaharin Anwar Sulaiman

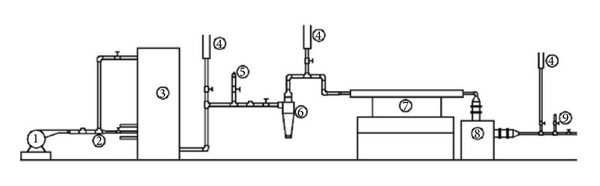

Biomass wastes produced from oil palm mills and plantations include empty fruit bunches (EFBs), shells, fibers, trunks, and oil palm fronds (OPF). EFBs and shells are partially utilized as boiler fuel while the rest of the biomass materials like OPF have not been utilized for energy generation. No previous study has been reported on gasification of oil palm fronds (OPF) biomass for the production of fuel gas. In this paper, the effect of moisture content of fuel and reactor temperature on downdraft gasification of OPF was experimentally investigated using a lab scale gasifier of capacity 50 kW. In addition, results obtained from equilibrium model of gasification that was developed for facilitating the prediction of syngas composition are compared with experimental data. Comparison of simulation results for predicting calorific value of syngas with the experimental results showed a satisfactory agreement with a mean error of 0.1 MJ/Nm3. For a biomass moisture content of 29%, the resulting calorific value for the syngas was found to be only 2.63 MJ/Nm3, as compared to nearly double (4.95 MJ/Nm3) for biomass moisture content of 22%. A calorific value as high as 5.57 MJ/Nm3 was recorded for higher oxidation zone temperature values.

Posted on: January 2014

Authored: Shaharin Anwar Sulaiman