Effect of particle size and temperature on gasification performance of coconut and palm kernel shells in downdraft fixed-bed reactor

Author: Shaharin Anwar Sulaiman - May 2019

Abstract

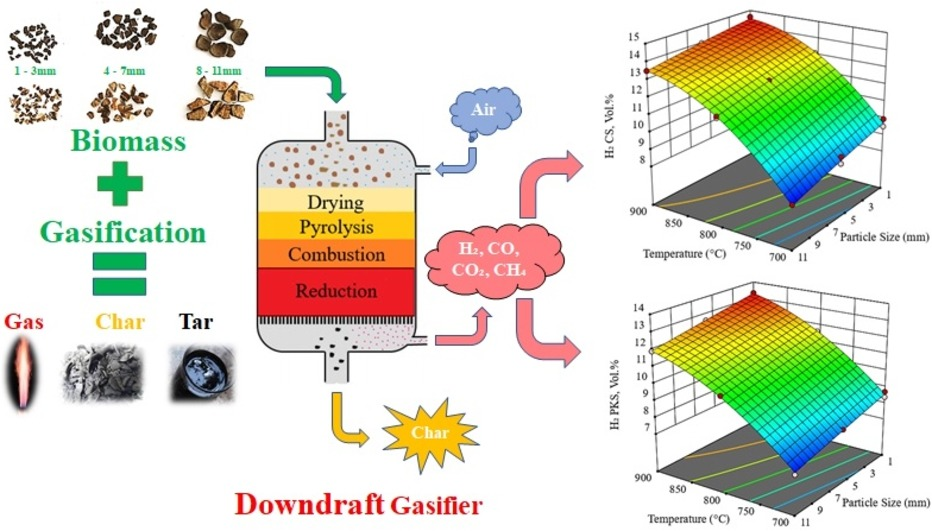

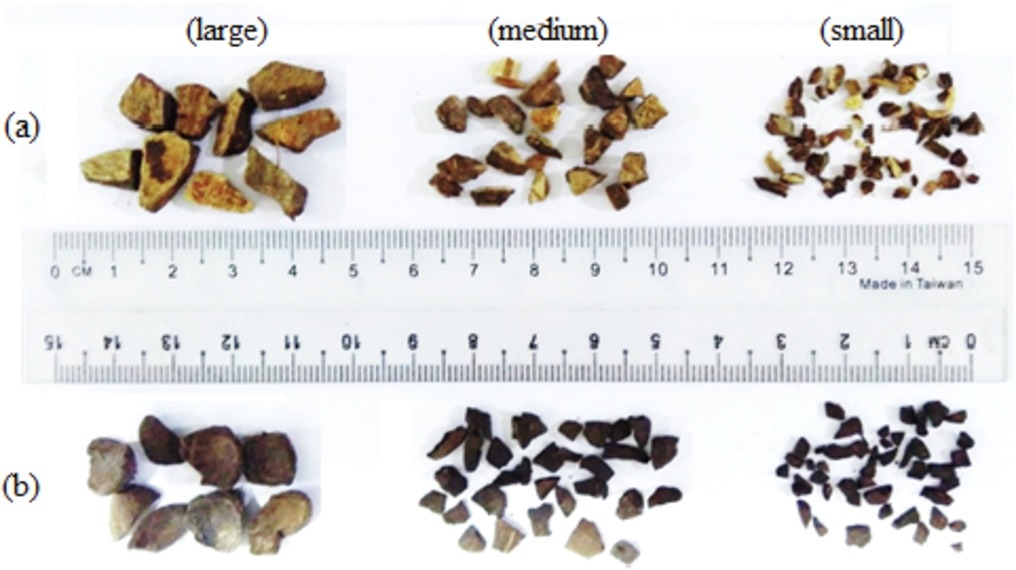

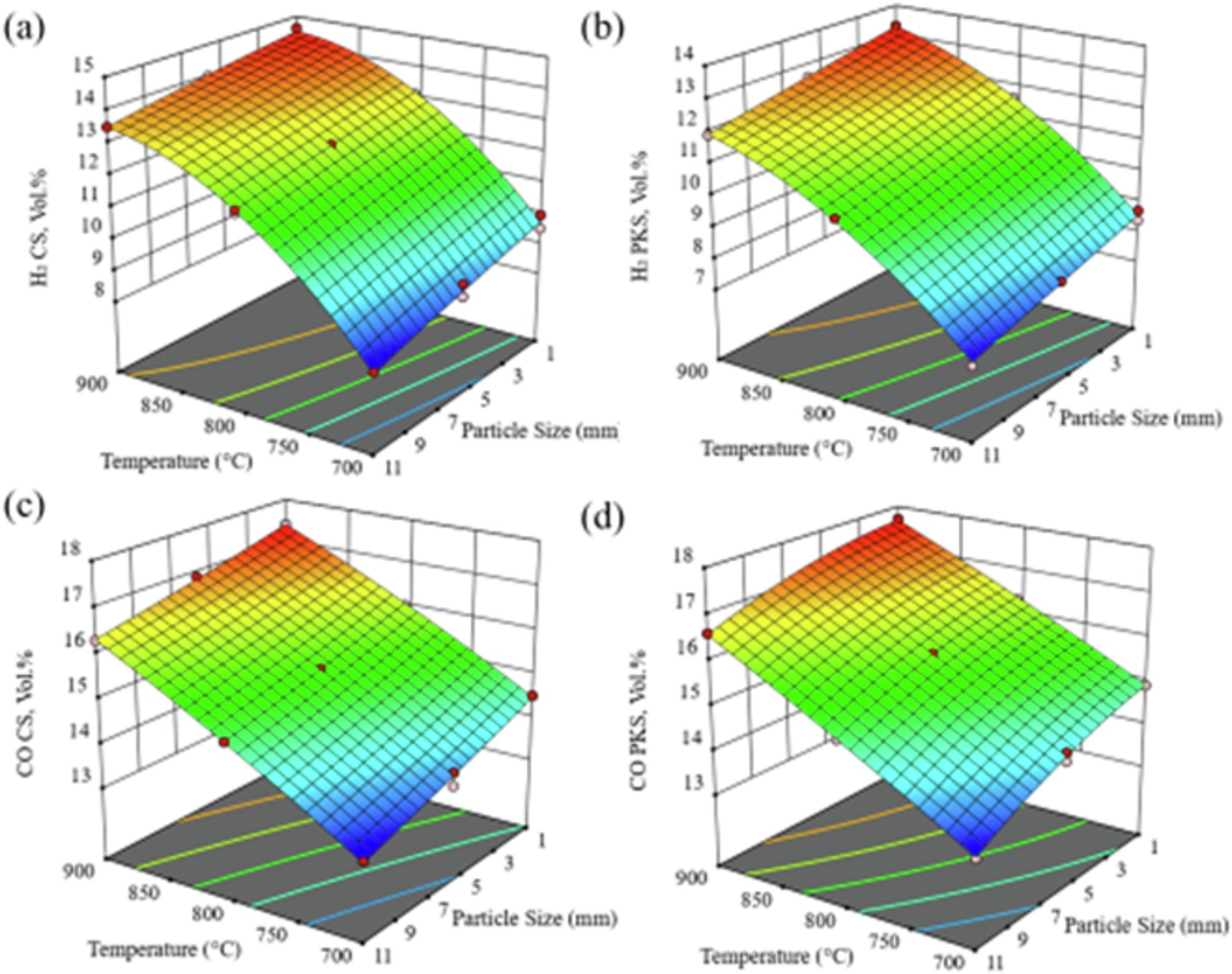

Gasification of coconut shell (CS) and palm kernel shell (PKS) is conducted in a batch type downdraft fixed-bed reactor to evaluate the effect of particle size (1-3 mm, 4-7 mm, and 8-11 mm) and temperature (700, 800, and 900 °C) on gas composition and gasification performance. The response surface methodology integrated variance-optimal design is used to identify the optimum condition for gasification. Gas composition, which is measured using the biomass particle size of 1-11 mm at 700-900 °C, are 8.20-14.6 vol% (H2), 13.0-17.4 vol% (CO), 14.7-16.7 vol% (CO2), and 2.82-4.23 vol% (CH4) for CS and 7.01-13.3 vol% (H2), 13.3-17.8 vol% (CO), 14.9-17.1 vol% (CO2), and 2.39-3.90 vol% (CH4) for PKS. At similar conditions, the syngas higher heating value, dry gas yield, carbon conversion efficiency, and cold gas efficiency are 4.01-5.39 MJ/Nm3, 1.50-1.95 Nm3/kg, 52.2-75.9%, and 30.9-56.4% for CS, respectively, and 3.82-5.09 MJ/Nm3, 1.48-1.92 Nm3/kg, 59.0-81.5%, and 33.0-57.1% for PKS, respectively. Results reveal that temperature has a greater role than particle size in influencing the gasification reaction rate.

Methodology

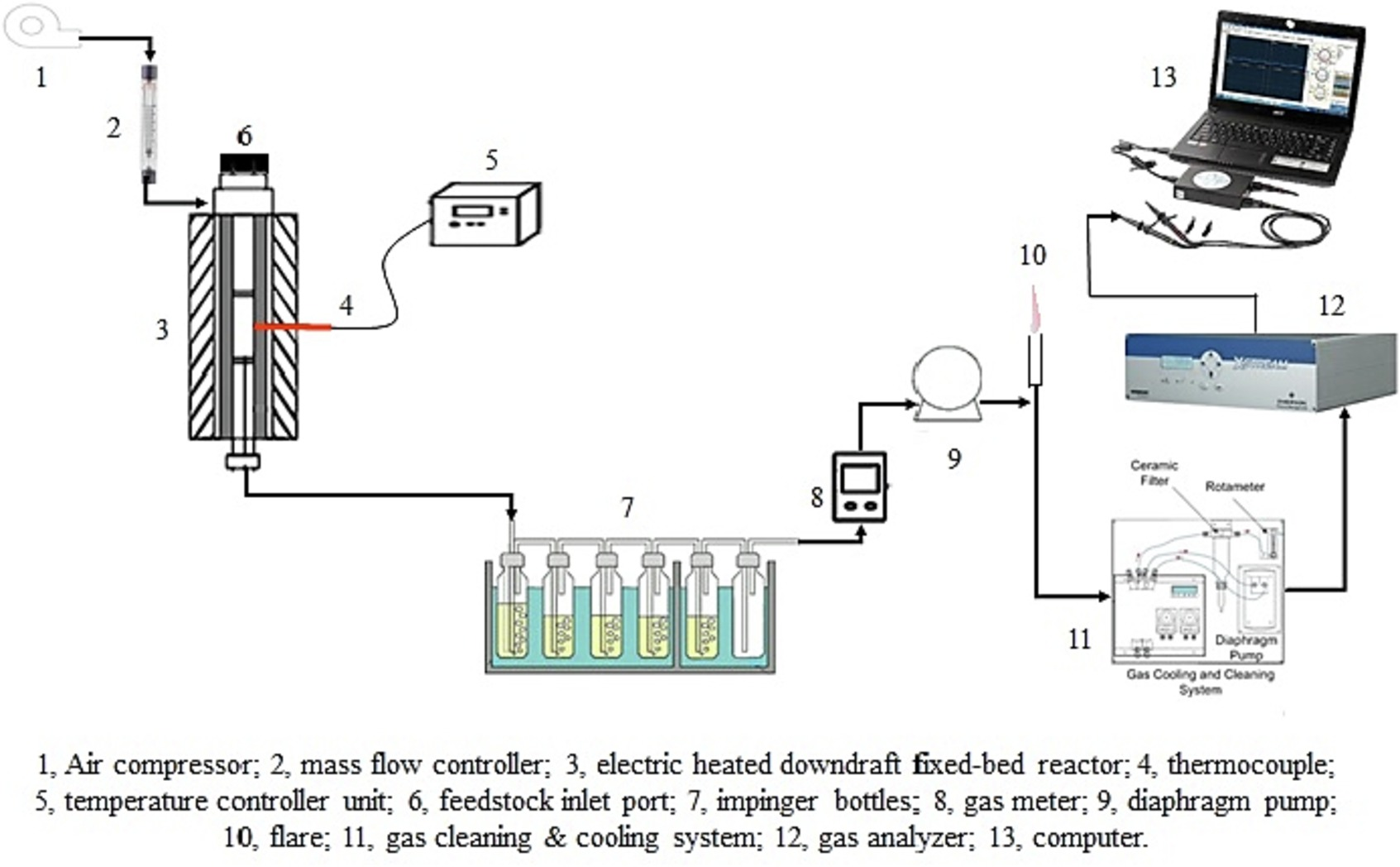

A batch-type downdraft fixed-bed with an electrically heated reactor was made from a stainless steel tube with a diameter of 5.08 cm and a height of 50 cm. A ceramic electrical type was used to supply the desired heat for start-up and maintain heat loss during the operation. The operating temperature was measured by an external PID controller coupled with a K-type thermocouple mounted on the gasifier reactor. The system was heated up to the desired operation temperature of 700 °C at start-up. The system operating temperature was then increased to 800 °C and 900 °C. Air, as a gasification agent, was generated from a 20-gallon air compressor, and the compressed air was introduced into the reactor. Rather than steam or a mixture of air and steam, air was chosen as the gasifying agent to avoid additional costs for steam generation. An equivalent ratio (ER) of 2.2 was applied for CS and PKS gasification because it is the optimum condition for the applied downdraft reactor. As the desired temperature was reached, a certain amount of feedstock was fed through the open top of the gasifier. The reproducibility of the gasification results was evaluated by repeating three sets of experiments under similar operational conditions.

Impact & Benefits

Optimized Gasification Efficiency: Understanding how particle size and temperature affect gasification performance helps in optimizing the process parameters. Fine tuning these variables can lead to higher gas yields and improved overall efficiency of biomass conversion to syngas.

Increased Syngas Quality: Fine-tuning particle size and temperature can lead to the production of syngas with desired composition and quality. This is crucial for applications such as power generation or synthesis of fuels and chemicals, where the quality of the syngas directly impacts the performance of downstream processes.

Resource Utilization: Utilizing coconut and palm kernel shells for gasification reduces the reliance on fossil fuels and helps in utilizing agricultural waste or by-products effectively. This contributes to sustainability and mitigates environmental concerns associated with waste disposal.

Economic Viability: Improving gasification performance can enhance the economic viability of biomass-to-energy projects. Higher gas yields and better quality syngas mean increased energy output per unit of biomass feedstock, which can improve the project's profitability.

Market Potential

Renewable Energy Demand: With growing concerns about climate change and the need to reduce greenhouse gas emissions, there is a significant global demand for renewable energy sources. Biomass gasification, particularly from agricultural waste such as coconut and palm kernel shells, presents a promising solution to meet this demand.

Resource Availability: Coconut and palm kernel shells are abundant agricultural residues in regions where coconut and oil palm cultivation are prevalent, such as Southeast Asia, Africa, and parts of South America. This ensures a steady and potentially low-cost supply of feedstock for gasification projects utilizing these biomass sources.

Technology Adoption: As gasification technology continues to mature and become more efficient, there is increasing interest in optimizing process parameters such as particle size and temperature to enhance performance. Research in this area can lead to the development of improved gasification systems and processes, driving greater adoption of biomass gasification for energy production.

Market Opportunities: The market potential extends beyond just energy generation. Syngas produced from biomass gasification can be utilized for various applications, including power generation, heat production, and synthesis of fuels and chemicals. The versatility of syngas opens up diverse market opportunities across different sectors.