Parametric analysis and optimization for the catalytic air gasification of palm kernel shell using coal bottom ash as catalyst

Author: Shaharin Anwar Sulaiman - January 2020

Abstract

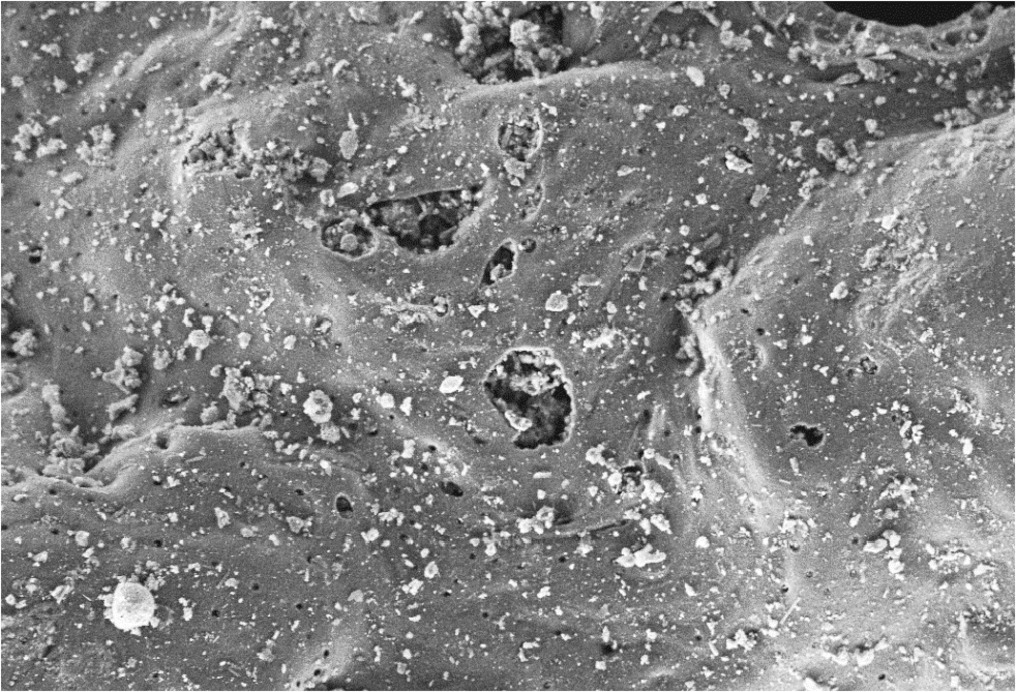

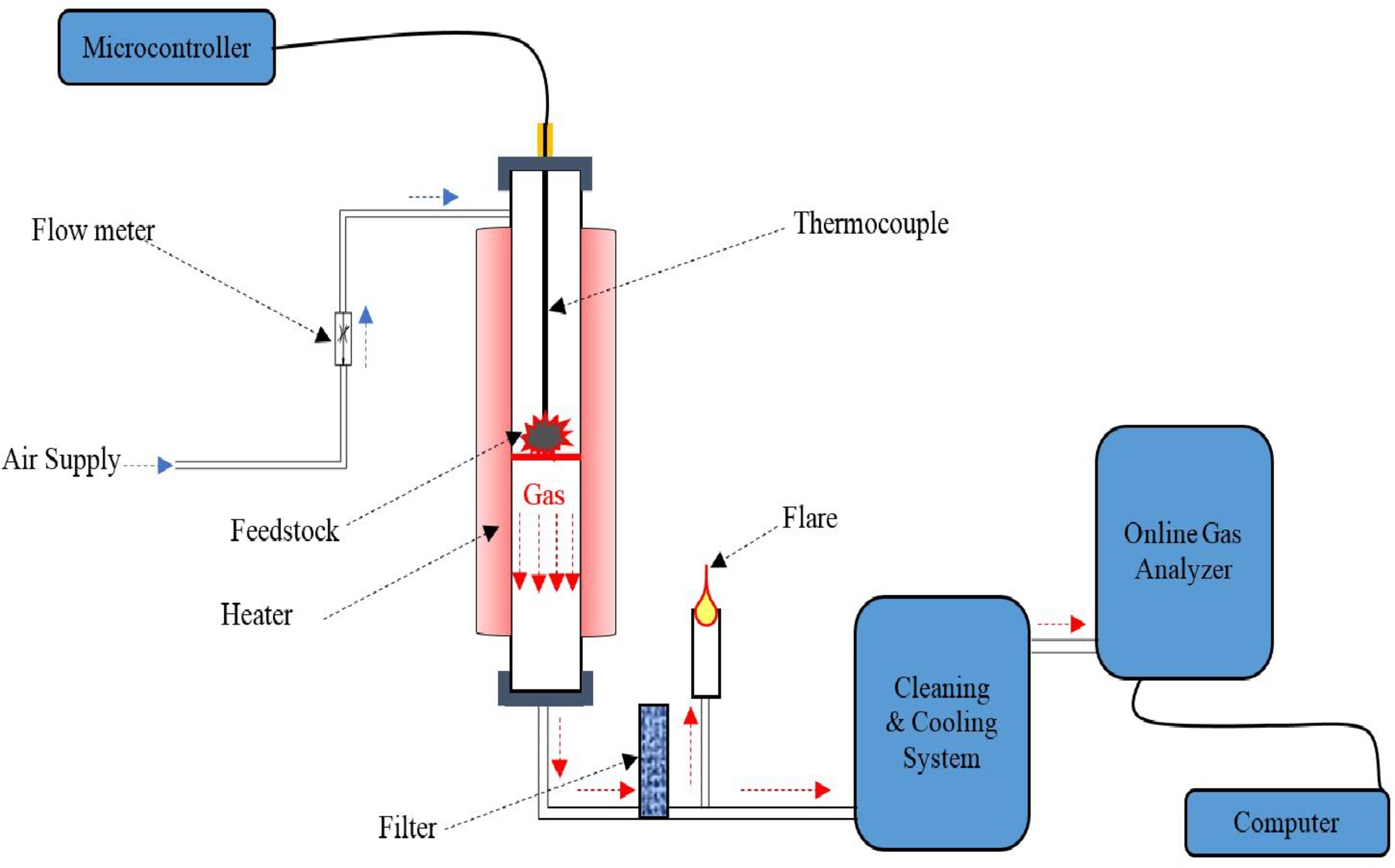

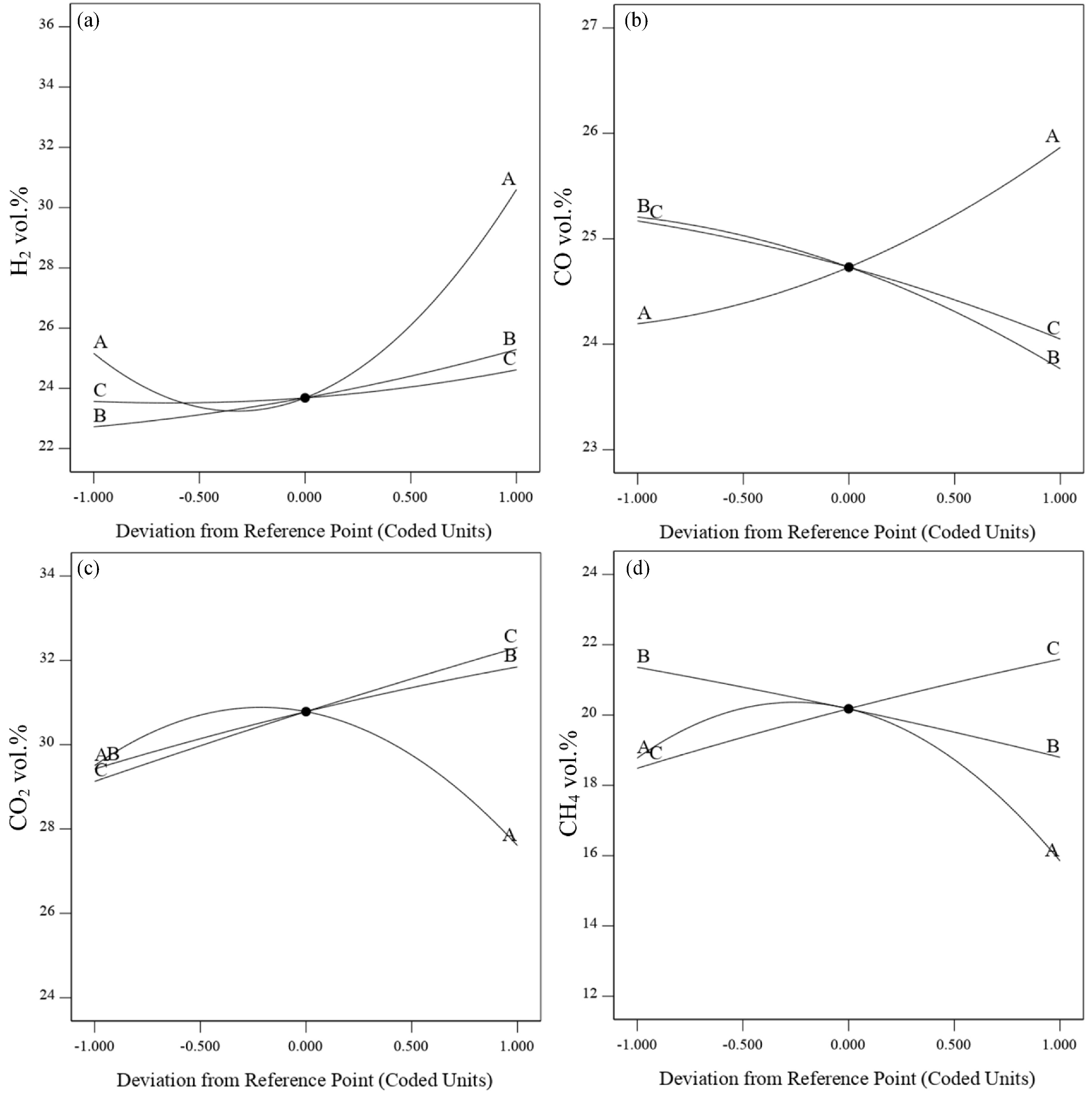

The air gasification of palm waste specifically palm kernel shell has been performed in the fixed bed gasifier using coal bottom ash as a potential catalyst. Effect of the process variables (temperature, catalyst loading, and airflow rate) has been investigated on the product gas composition. The design of experiments was accomplished using the Design Expert v11 with a Central Composite Design approach. Moreover, the parametric study and optimization of the entire process have been carried out using Response Surface Methodology within the specific range of variables. The results suggested that the temperature has been found as the most influencing parameter for increment of H2 and CO production. Whereas, airflow rate was more sensitive for CH4 and CO2 production. Catalyst loading was found very effective for the amplified amount of H2 and CO production and the reduction in the amounts of CO2 and CH4, caused by the catalytic activity of coal bottom ash (CBA). Optimized parameters are found to be the temperature of 850 °C, catalyst loading of 14.50 wt%, and airflow rate of 2.50 L/min, which predicted the composition for H2 of 31.38 vol%, CO of 26.44 vol%, CH4 of 15.67 vol%, and CO2 of 25.59 vol%.

Methodology

Temperature is one of the most crucial parameters considered in the gasification process that influences the devolatilization process at all stages of gasification and its product gas composition [34]. The conversion of biomass into gaseous products increases with an increase in the temperature due to the high volatile matter of biomass that enhances the solid to gas conversion at high temperature. The conversion of solid into the gaseous products also occurred in second phase due to the char gasification, methane reforming, and Boudouard reaction in gasification. Methane reforming, water gas shift reaction, and tar cracking were enhanced with the increase in temperature that increases the H2 and CO content in the product gas. On the other hand, at lower temperatures, methane formation occurred which increased the CH4 content in the product gas [83]. Furthermore, tar cracking and reforming are endothermic reactions and enhance the gas yield at high temperature. The effect of temperature in discrete biomass gasification has been studied by many researchers. The effect of temperature on different blended feedstocks in gasification is also important due to the presence of different hydrogen, carbon, and oxygen ratios (H/C and O/C) of two or more materials gasified at the same time in a gasifier. It is also important to consider the effect of catalysts used in the co-gasification of blended feedstock on the temperature of the gasification process.

Impact & Benefits

Efficiency Improvement: Parametric analysis helps identify key variables affecting the gasification process, such as temperature, pressure, feedstock composition, and catalyst-to-feed ratio. Optimization allows fine-tuning these parameters to maximize gasification efficiency, leading to higher yields of desired products like syngas (a mixture of hydrogen and carbon monoxide) from PKS.

Resource Utilization: By optimizing the use of coal bottom ash as a catalyst, which is often considered a waste material from coal-fired power plants, the process contributes to resource utilization and waste minimization. This not only reduces environmental impact but also lowers the overall cost of the gasification process.

Emission Reduction: Efficient gasification with proper catalyst utilization can lead to reduced emissions of harmful gases such as carbon monoxide, particulate matter, and sulfur compounds compared to conventional combustion processes. This contributes to cleaner air quality and mitigates the environmental footprint of energy generation from biomass.

Product Quality Enhancement: Through parametric analysis and optimization, the quality of the syngas produced can be improved. This includes adjusting the gas composition to meet specific requirements for downstream applications such as power generation, fuel synthesis, or chemical production. Optimizing catalyst performance ensures better conversion of biomass into desired gas components.

Market Potential

Demand for Sustainable Energy Solution: There's a growing global demand for sustainable energy solutions due to concerns about climate change and the depletion of fossil fuels. Processes like catalytic gasification of biomass offer a more sustainable alternative.

Availability of Feedstock: Palm kernel shells are abundant in regions where palm oil production is prevalent, such as Southeast Asia and Africa. The availability of such biomass feedstock is a key factor in the market potential of this process.

Environmental Regulations: Stringent environmental regulations in many countries drive industries to adopt cleaner technologies. Catalytic gasification offers potential advantages in terms of reducing emissions compared to conventional combustion methods.

Cost Competitiveness: The cost-effectiveness of the process compared to other energy generation methods is crucial. This includes not only the cost of the technology itself but also the cost of feedstock, catalyst, and operation.