Influence of Fuel Moisture Content and Reactor Temperature on the Calorific Value of Syngas Resulted from Gasification of Oil Palm Fronds

Author: Shaharin Anwar Sulaiman - January 2014

Abstract

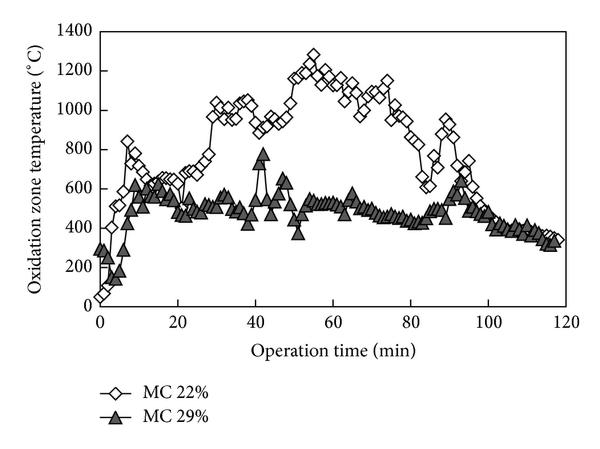

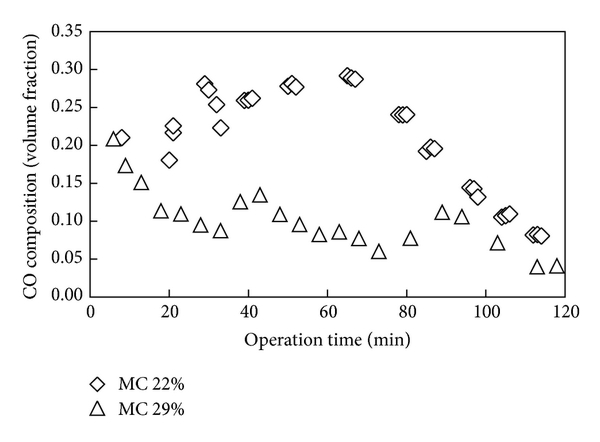

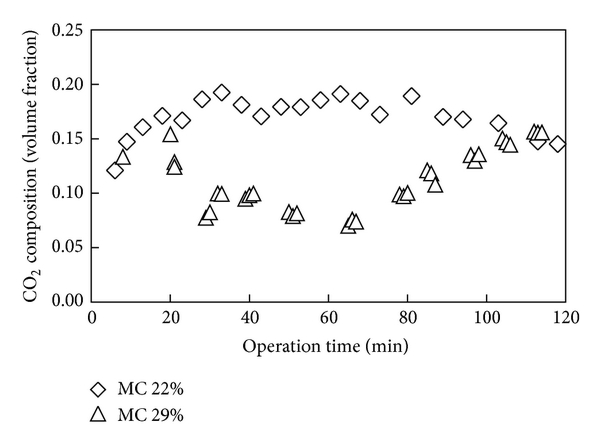

Biomass wastes produced from oil palm mills and plantations include empty fruit bunches (EFBs), shells, fibers, trunks, and oil palm fronds (OPF). EFBs and shells are partially utilized as boiler fuel while the rest of the biomass materials like OPF have not been utilized for energy generation. No previous study has been reported on gasification of oil palm fronds (OPF) biomass for the production of fuel gas. In this paper, the effect of moisture content of fuel and reactor temperature on downdraft gasification of OPF was experimentally investigated using a lab scale gasifier of capacity 50 kW. In addition, results obtained from equilibrium model of gasification that was developed for facilitating the prediction of syngas composition are compared with experimental data. Comparison of simulation results for predicting calorific value of syngas with the experimental results showed a satisfactory agreement with a mean error of 0.1 MJ/Nm3. For a biomass moisture content of 29%, the resulting calorific value for the syngas was found to be only 2.63 MJ/Nm3, as compared to nearly double (4.95 MJ/Nm3) for biomass moisture content of 22%. A calorific value as high as 5.57 MJ/Nm3 was recorded for higher oxidation zone temperature values.

Methodology

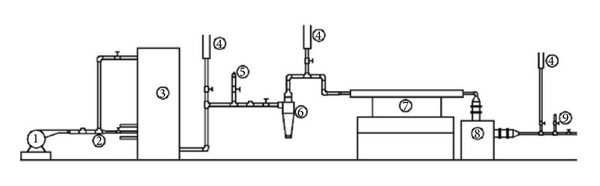

The experimental rig used was a batch feed downdraft gasifier. The operation was carried out at atmospheric condition using air as a gasification medium. The design capacity of the gasifier used was 50 kW of thermal output. The reactor was cylindrical with a height of 1000 mm and diameter of 400 mm. A necking or throat of slope angle of 70° was provided near the grate of the gasifier in order to ensure smooth downflow of the biomass by gravity. In order to decrease energy loss due to heat transfer, the gasifier wall was insulated with refractory cement material of thickness 25 mm. The details on the gasifier design were presented in the work of Moni and Sulaiman. The schematic of the experimental setup is shown in Figure 1. The experimental setup consisted of a blower for the supply of air and a number of syngas conditioning units downstream of the gasifier. The conditioning units used for the cooling and cleaning of syngas include a cyclone, condenser, and oil bath filter which were provided before the cleaned gas sampling point. In addition, as shown in Figure 1 a number of flare points were provided on the outlet piping in order to check the combustibility of produced syngas and to burn poisonous gases like CO produced from gasification, before being released to the atmosphere. A multipurpose Emerson X2GP gas analyzer was used to measure volume percentage of the major component gases: CO, CO2, CH4, and H2 in the syngas produced.

Impact & Benefits

Calorific Value Optimization: Understanding how moisture content and reactor temperature affect the calorific value of syngas allows for optimization of these parameters to maximize the energy content of the syngas produced. Higher calorific value means more energy is available for combustion or conversion into other forms of energy, such as electricity or heat.

Efficiency Improvement: By optimizing the gasification process based on these factors, the overall efficiency of syngas production can be improved. This efficiency gain is crucial for making gasification a viable and competitive energy generation technology.

Resource Utilization: Oil palm fronds are a biomass waste product abundant in regions where oil palm cultivation is prevalent. Gasification provides a means of converting this waste into a useful energy source, thereby improving resource utilization and reducing waste disposal issues.

Environmental Benefits: Gasification of biomass like oil palm fronds can offer environmental benefits compared to traditional fossil fuel combustion. Syngas produced from biomass gasification typically has lower emissions of greenhouse gases and pollutants such as sulfur dioxide and particulate matter, contributing to reduced environmental impact and improved air quality.

Market Potential

Abundance of Feedstock: Oil palm fronds are a readily available biomass feedstock in regions where oil palm cultivation is widespread, such as Southeast Asia, Africa, and parts of South America. The abundance of this feedstock provides a consistent and reliable source for syngas production through gasification.

Energy Security and Diversification: Many countries are seeking to enhance their energy security by diversifying their energy sources and reducing reliance on fossil fuels. Utilizing oil palm fronds for syngas production contributes to this diversification by providing a renewable and locally available energy source.

Environmental Regulations and Sustainability Goals: Stringent environmental regulations and sustainability goals are driving the adoption of renewable energy technologies worldwide. Gasification of oil palm fronds offers a sustainable alternative to fossil fuel combustion, aligning with these regulatory requirements and sustainability objectives.

Technological Advancements: Advances in gasification technology, coupled with research on optimizing parameters such as fuel moisture content and reactor temperature, are improving the efficiency and viability of syngas production from biomass feedstocks. This technological progress enhances the market potential by making biomass gasification more economically competitive and technically feasible.