Syngas (H2/CO) in a spark-ignition direct-injection engine. Part 1: Combustion, performance and emissions comparison with CNG

Author: Shaharin Anwar Sulaiman - October 2014

Abstract

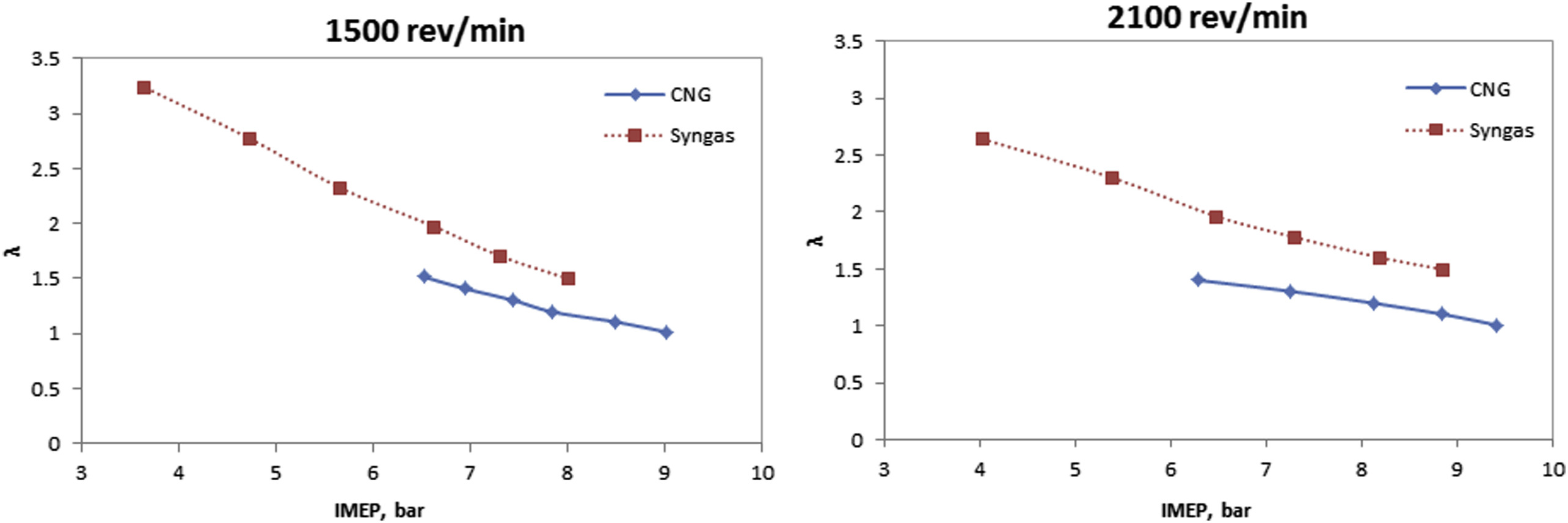

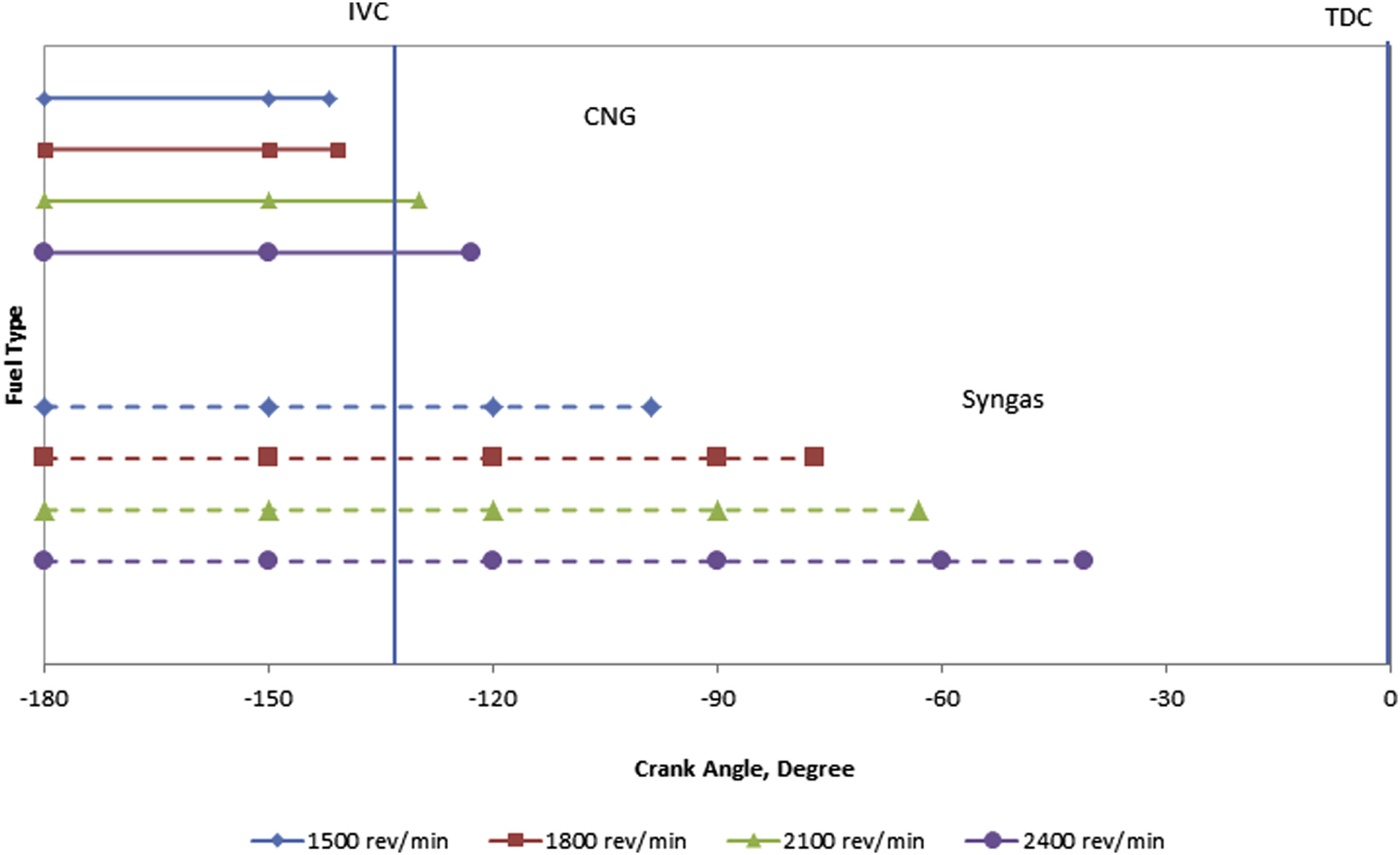

The combustion, performance, and emissions of syngas (H2/CO) in a four-stroke, direct-injection, spark-ignition engine were experimentally investigated. The engine was operated at various speeds, ranging from 1500 to 2400 rev/min, with the throttle being held in the wide-open position. The start of fuel injection was fixed at 180° before the top dead center, and the ignition advance was set at the maximal brake torque. The air/fuel ratio was varied from the technically possible lowest excess air ratio (λ) to lean operation limits. The results indicated that a wider air/fuel operating ratio is possible with syngas with a very low coefficient of variation. The syngas produced a higher in-cylinder peak pressure and heat-release rate peak and faster combustion than for CNG. However, CNG produced a higher brake thermal efficiency (BTE) and lower brake specific fuel consumption (BSFC). The BTE and BSFC of the syngas were on par to those of CNG at higher speeds. For the syngas, the total hydrocarbon emission was negligible at all load conditions, and the carbon monoxide emission was negligible at higher loads and increased under lower load conditions. However, the emission of nitrogen oxides was higher at higher loads with syngas.

Methodology

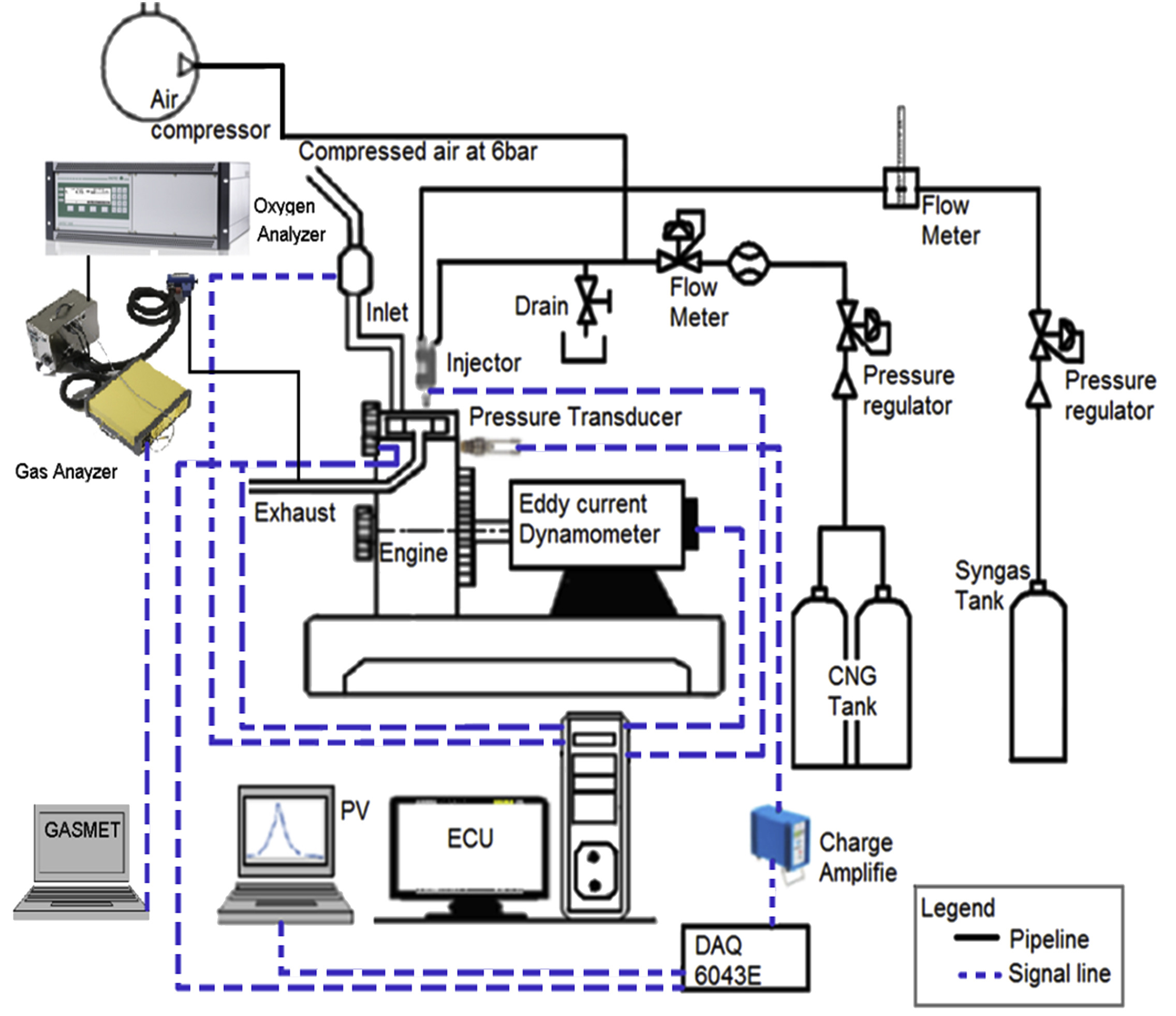

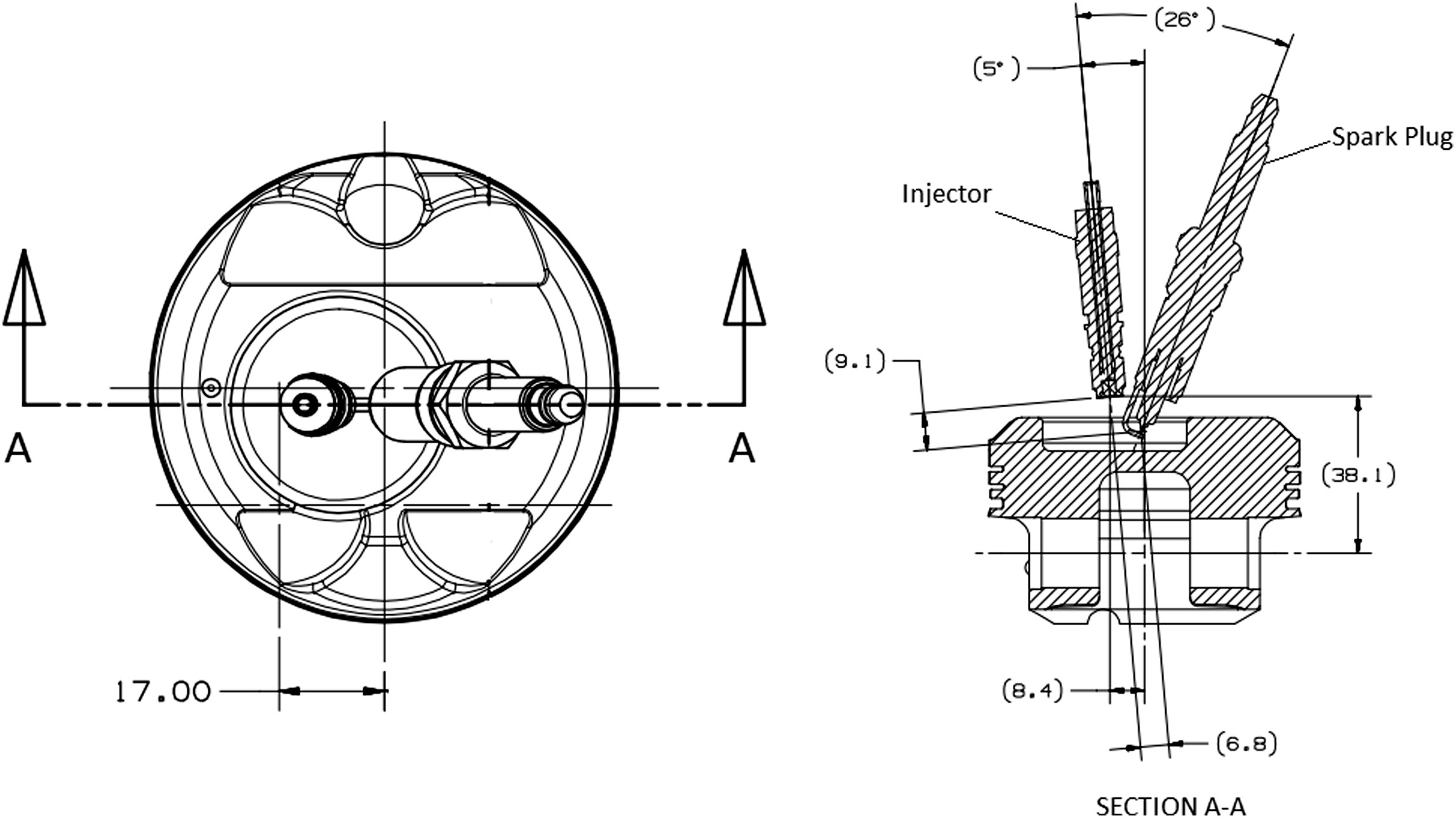

The study was conducted in a four-stroke, single-cylinder, DISI research engine developed by Orbital with a compression ratio of 14:1; its schematic diagram is shown in Fig. 1, and its specifications are listed in Table 1. The study was conducted in the Center for Automotive Research and Electric Mobility (CAREM), Universiti Teknologi PETRONAS. The experiments were conducted in accordance with the Society of Automotive Engineers (SAE) standards of Engine Power Test Code. The engine was coupled to an eddy-current electric dynamometer to measure the brake torque and further to motor the engine at times of no combustion. At early fuel-injection times, the charge has enough time to mix with air before the onset of ignition. As a result, the shape of the piston head has less significance in the charge-mixing process. However, there is insufficient time for charge mixing in late-injection operations, resulting in an uneven air/fuel ratio in the cylinder. The shape of the piston head and the SOI at late injection influences the distribution of charge in the chamber. In this work, a large piston bowl that creates fuel stratification in the chamber was selected. In this arrangement, the bowl position was away from the center aligned with the injector and spark plug position. As a result, the fuel is deflected back from the piston, creating a richer mixture near the spark plug. Such fuel stratification reduces the combustion instability and increases the mixture-distribution quality in the cylinder at a lean air/fuel ratio. The arrangement of the piston, injector and spark plug is depicted in Fig. 2. The injection system was a central DI in which the injector was placed with its axis aligned with the center of the piston bowl and had a 6-mm offset to the spark plug. An air injector was used for the study without any modification. The fuel injection was kept at 18 bar.

Impact & Benefits

Combustion Characteristics: Syngas has different combustion characteristics compared to CNG due to its composition. It has a higher flame speed and wider flammability limits compared to methane, the primary component of CNG. This can result in improved combustion stability and potentially higher thermal efficiency. Compressed natural gas typically consists mainly of methane, which has well-known combustion properties. However, its flame speed and flammability limits may not be as favorable as syngas in all operating conditions.

Performance: The use of syngas can potentially improve engine performance, including increasing power output and torque due to its higher octane rating and better anti-knock properties compared to CNG. It may also allow for higher compression ratios, further enhancing engine performance. While CNG is a viable fuel for spark-ignition engines, its lower energy density compared to gasoline can result in slightly reduced power output and torque. However, its clean combustion characteristics often lead to lower engine wear and maintenance costs.

Emissions: Syngas combustion typically produces lower levels of pollutants such as nitrogen oxides (NOx) and particulate matter (PM) compared to conventional gasoline or diesel fuels. Additionally, since hydrogen is a clean-burning fuel, using syngas can result in lower emissions of carbon monoxide (CO) and hydrocarbons (HC) compared to CNG. Compressed natural gas is known for its low emissions profile, particularly in terms of NOx and particulate matter. However, it may produce slightly higher levels of CO2 compared to syngas due to its higher carbon content.

Fuel Availability and Production: Syngas production typically involves gasification of biomass, coal, or other carbon-containing feedstocks, followed by a cleaning and conditioning process to remove impurities. The availability and cost of feedstocks, as well as the complexity of the gasification process, can impact the widespread adoption of syngas as a transportation fuel. Compressed natural gas is readily available in many regions, particularly where natural gas infrastructure is well-established. It can be sourced from conventional natural gas reserves or renewable sources such as biogas.

Market Potential

Combustion Efficiency: Syngas combustion efficiency and its ability to generate power in SIDI engines need to be evaluated. Higher combustion efficiency can lead to better fuel economy and overall performance.

Performance Metrics: Metrics such as power output, torque, and acceleration need to be compared between syngas and CNG. Higher performance metrics could make syngas more attractive to consumers and industries.

Emissions Profile: Assessing the emissions profile of syngas compared to CNG is crucial. Syngas may offer potential environmental benefits if it produces lower emissions of pollutants such as CO2, NOx, and particulate matter.

Fuel Availability and Infrastructure: The availability of syngas and CNG, as well as the existing infrastructure for distribution and refueling, will impact market potential. CNG infrastructure is more established in some regions, but advancements in syngas production and distribution could expand its market reach.