Research Success Stories

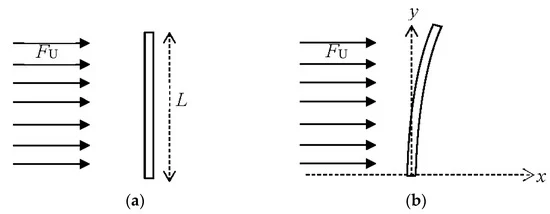

The utilization of a rigid and projecting surface, coupled with an agitator and vortex generator, frequently results in the dissipation of more energy than the production of turbulence that meets the required criteria. By contrast, a passively oscillating flexible protruding surface can generate a greater turbulence level. In the current study, a circular finite cylinder (cantilever) was used as the geometry of the rigid and protruding surface. Both the material and the aspect ratio were varied. Also, a local Reynolds number within the subcritical flow range (102 < ReD < 105) was considered. The results from the rigid protruding surface (finite cylinder) serve as a validation of the published results and a benchmark for the improvement of the turbulence generated by the flexible protruding surface. The results obtained via an ultrasonic velocity profiler have further demonstrated that the flexible cylinder is capable of generating greater turbulence by examining the turbulence intensity, the turbulence production term and the Reynolds stress. All the flexible cylinders that oscillate show an increase in turbulence production but at different percentages. The cylinders studied in this work ranged from the least structural stiffness (EVA) to moderate (aluminum) and the highest structural stiffness (carbon steel). Through studying the normalized amplitude responses graph for the flexible cylinders, it is found that the oscillating motion does indeed contribute to the increment. A further examination of the results shows that the increase is due to the structural velocity instead of just the oscillating motion.

Posted on: October 2023

Authored: Shaharin Anwar Sulaiman

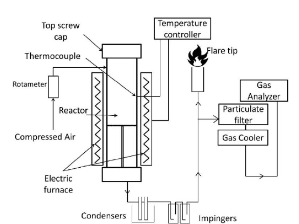

Plastic waste management has been a problem as most of the plastics are not biodegradable. Although plastics are recyclable, only 21% of total plastic wastes are recycled. Using plastics as gasification feedstock/co-feedstock and converting it to usable energy is one of the solutions of removing plastics waste. Co-gasifying polystyrene (PS) with palm kernel shell (PKS) is promising as both of the feedstocks are abundant and have high energy content. However, the performance of air gasification of PKS and PS has not been studied previously. In this work, co-gasification of PKS and PS was carried out, focusing on the effect of PS content in the feedstock. The PS content was varied from 0 to 30 wt%. By increasing the PS content, the CH4 volume percentage increases, while CO and H2 volume percentage decreases. The high heating value of the producer gas increases with PS content, from 11.95 MJ/Nm3 at 10 wt% PS, to 12.36 MJ/Nm3 at 30 wt% PS. Higher PS content also increases the gas yield percentage.

Posted on: June 2020

Authored: Shaharin Anwar Sulaiman

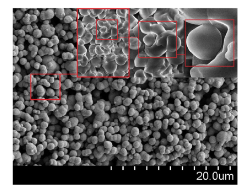

The world does not have too much time to ensure that the fast-growing population has enough land, food, water and energy. The rising food demand has brought a positive surge in fertilizers' demand and agriculture-based economy. The world is using 170 million tons of fertilizer every year for food, fuel, fiber, and feed. The nitrogenous fertilizers are being used to meet 48% of the total food demand of the world. High fertilizer inputs augment the reactive nitrogen levels in soil, air, and water. The unassimilated reactive nitrogen changes into a pollutant and harms the natural resources. The use of controlled-release fertilizers for slowing down the nutrients' leaching has recently been practiced by farmers. However, to date, monitoring of the complete discharge time and discharge rate of controlled released fertilizers is not completely understood by the researchers. In this work, corn starch was thermally processed into a week gel-like coating material by reacting with urea and borate. The granular urea was coated with native and processed starch in a fluidized bed reactor having bottom-up fluid delivery system. The processed starch exhibited better thermal and mechanical stability as compared to the native starch. Unlike the pure starch, the storage modulus of the processed starch dominated the loss modulus. The release time of urea, coated with processed starch, remained remarkably larger than the uncoated urea.

Posted on: April 2020

Authored: Shaharin Anwar Sulaiman