The Effects of Flexible Cylinder Structural Dynamics to the near Wake Turbulence

Author: Shaharin Anwar Sulaiman - October 2023

Abstract

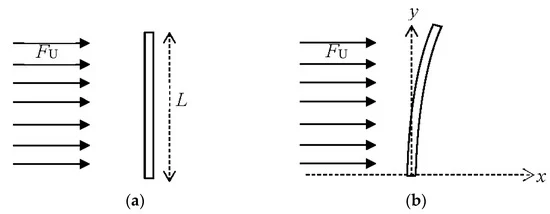

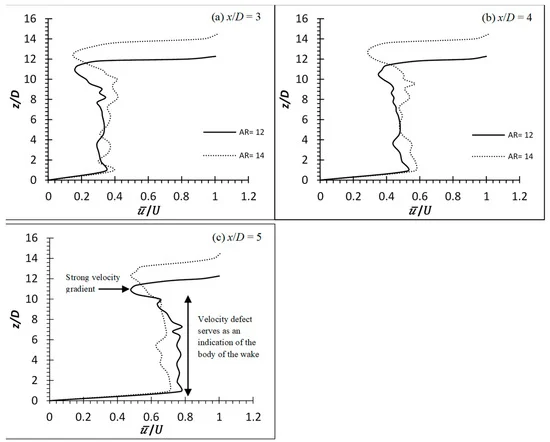

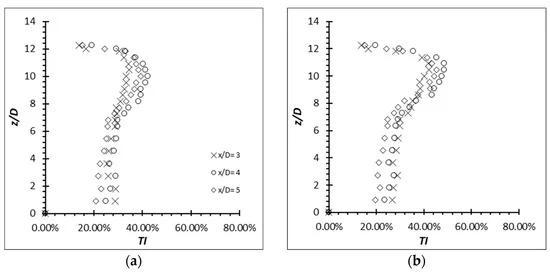

The utilization of a rigid and projecting surface, coupled with an agitator and vortex generator, frequently results in the dissipation of more energy than the production of turbulence that meets the required criteria. By contrast, a passively oscillating flexible protruding surface can generate a greater turbulence level. In the current study, a circular finite cylinder (cantilever) was used as the geometry of the rigid and protruding surface. Both the material and the aspect ratio were varied. Also, a local Reynolds number within the subcritical flow range (102 < ReD < 105) was considered. The results from the rigid protruding surface (finite cylinder) serve as a validation of the published results and a benchmark for the improvement of the turbulence generated by the flexible protruding surface. The results obtained via an ultrasonic velocity profiler have further demonstrated that the flexible cylinder is capable of generating greater turbulence by examining the turbulence intensity, the turbulence production term and the Reynolds stress. All the flexible cylinders that oscillate show an increase in turbulence production but at different percentages. The cylinders studied in this work ranged from the least structural stiffness (EVA) to moderate (aluminum) and the highest structural stiffness (carbon steel). Through studying the normalized amplitude responses graph for the flexible cylinders, it is found that the oscillating motion does indeed contribute to the increment. A further examination of the results shows that the increase is due to the structural velocity instead of just the oscillating motion.

Methodology

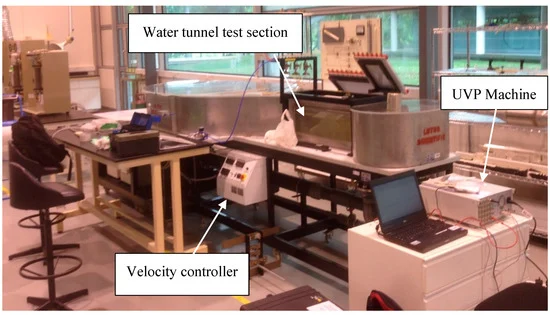

These objectives are achieved experimentally in an open channel water tunnel, as shown in Figure 3. To gain insights into the flow behavior, an ultrasonic velocity profiler (UVP), capable of measuring velocity vectors as a function of both space and time in a unidimensional Eulerian frame, was used to obtain the velocity vectors. The calibration of the 2 MHz transducer was carried out by positioning it at a trajectory angle that has the minimum Doppler angle error possible which is used in speed calculations. As stated by Yokoyama et al. [20], at least two transducers are needed for measuring two-dimensional flow and three transducers for three-dimensional flow. This is because each transducer is needed to measure each velocity component at one spatial point to form a vector. The vector is therefore obtained from any two non-parallel measured components. As the vector component is an orthogonal projection of a true vector into a measuring line (Figure 4), therefore, a large projection angle between the two transducers is encouraged to avoid large inaccuracy in direction estimation. In other words, two-dimensional flow or three-dimensional flow measurements, unlike the technique of one-dimensional flow measurements, rely solely on the orthogonal composition technique which in turn can only be achieved at their respective intersection points.

Impact & Benefits

Improved Understanding of Turbulence-Structure Interaction: Such studies deepen our understanding of the complex interactions between fluid dynamics (turbulence) and structural dynamics (flexible cylinders). This understanding can lead to more accurate predictive models and simulations, essential for designing efficient structures and optimizing fluid flow in various engineering applications.

Enhanced Performance of Engineering Systems: By understanding how flexible cylinders affect near wake turbulence, engineers can design structures and systems that minimize turbulence-induced drag or optimize energy extraction in applications such as wind energy, aerospace, marine engineering, and civil engineering (e.g., bridges, buildings).

Advancements in Renewable Energy: In the context of wind energy, for example, understanding how flexible structures influence wake turbulence can lead to more efficient wind turbine designs. Optimizing turbine placement and rotor configurations based on these insights can increase energy output and improve the overall efficiency of wind farms.

Reduced Environmental Impact: More efficient energy extraction from renewable sources like wind can contribute to a reduction in greenhouse gas emissions and dependence on fossil fuels, thereby mitigating climate change and its associated environmental impacts.

Market Potential

Wind Energy: The wind energy sector stands to benefit significantly from insights into how flexible structures interact with wake turbulence. By optimizing turbine designs and layouts based on this understanding, wind farm developers can increase energy output and reduce operational costs, thereby enhancing the economic viability of wind energy projects.

Aerospace: In the aerospace industry, understanding the effects of wake turbulence on aircraft structures can lead to the development of more efficient and aerodynamically optimized aircraft designs. This could translate into fuel savings for airlines and improved performance for military and commercial aircraft, driving demand for innovative engineering solutions.

Marine Engineering: Research in this area could also impact marine engineering, particularly in the design of offshore structures such as oil platforms, floating wind turbines, and marine vessels. By considering the interaction between flexible structures and turbulent flow, engineers can design more resilient and cost-effective marine infrastructure.

Civil Engineering: In civil engineering, insights into the effects of wake turbulence on structures like bridges, buildings, and towers can inform design practices to enhance structural stability and longevity. This could lead to increased demand for consulting services, software tools, and construction materials tailored to address dynamic environmental conditions.