Air co-gasification of palm kernel shell and polystyrene:Effect of different polystyrene content

Author: Shaharin Anwar Sulaiman - June 2020

Abstract

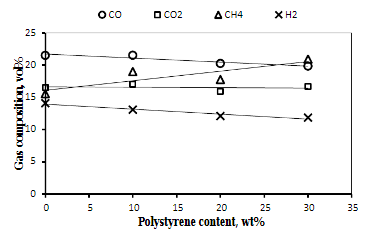

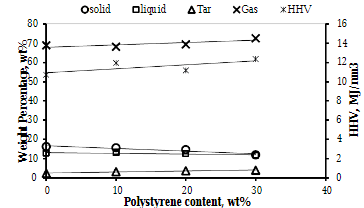

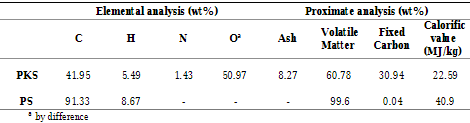

Plastic waste management has been a problem as most of the plastics are not biodegradable. Although plastics are recyclable, only 21% of total plastic wastes are recycled. Using plastics as gasification feedstock/co-feedstock and converting it to usable energy is one of the solutions of removing plastics waste. Co-gasifying polystyrene (PS) with palm kernel shell (PKS) is promising as both of the feedstocks are abundant and have high energy content. However, the performance of air gasification of PKS and PS has not been studied previously. In this work, co-gasification of PKS and PS was carried out, focusing on the effect of PS content in the feedstock. The PS content was varied from 0 to 30 wt%. By increasing the PS content, the CH4 volume percentage increases, while CO and H2 volume percentage decreases. The high heating value of the producer gas increases with PS content, from 11.95 MJ/Nm3 at 10 wt% PS, to 12.36 MJ/Nm3 at 30 wt% PS. Higher PS content also increases the gas yield percentage.

Methodology

Feedstocks blend with PS yields producer gas with higher HHV, compared to the gas produced by the gasification of PKS only. Adding 10 wt% of PS to the feedstock blend yielded gas with HHV value of 11.95 MJ/Nm3, an increase compared to the HHV value of gasification of PKS only, in which the HHV value of the producer gas is 10.72 MJ/Nm3. This can be explained by observing the gas composition of the producer gas, in which adding plastic will increase the CH4 content. CH4 has high HHV, so the increase of CH4 certainly affects the HHV value of the producer gas. Further increasing the PS content will show an increasing trend of HHV.

Impact & Benefits

Thermochemical Disposal: Thermochemical processes, specifically gasification technology, as a means of disposing of plastics. Gasification is presented as a method that uses heat to convert carbon materials to gas, which can be utilized as fuel or as a feedstock for chemical processes.

Plastic Waste Problem: The increasing issue of plastic waste, especially in Malaysia, where a significant portion of solid waste is comprised of plastic.

Potential Economic Benefits: If successful, the proposed method could have economic benefits by providing an effective and sustainable solution for plastic waste disposal.

Energy Recovery: Gasification technology offers the potential for energy recovery from plastic waste, contributing to the diversification of energy sources and reducing reliance on traditional fossil fuels.

Market Potential

Clogging Issues and Biomass Solution: The mention of clogging problems during the gasification of plastics and the proposed solution of mixing plastics with biomass (Palm Kernel Shell) suggests a market opportunity for technologies or processes that address these operational challenges.

Gas Composition and Heating Value Analysis: Analyze the gas composition and heating value of the producer gas, providing valuable data for potential applications of the gas produced through this process.

Thermochemical Process - Gasification: The exploration of gasification technology as a way to dispose of plastics indicates a market potential for advanced waste management technologies. Gasification is highlighted as a method to convert carbon materials to gas, presenting potential applications in fuel production or chemical processes.