Research Success Stories

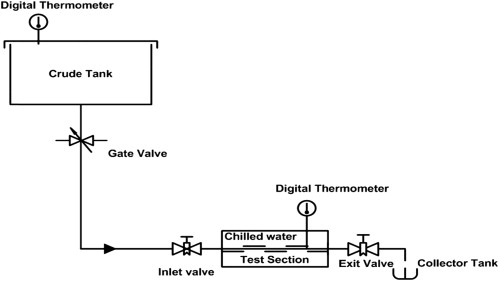

If a gel is formed when the flow of waxy crude oil within a pipeline is stopped for a period of time, the required restart pressure may be high and the line is costly to operate. The conventional method of predicting the restart pressure for gelled crude oil assumes a constant yield stress across and along the pipe section; this often leads to excessive over sizing of pump and piping system. Many researches highlighted that the presence of gas voids upon cooling of waxy crude may have an impact on the yield stress of gelled crude. This paper describes the use of Magnetic Resonance Imaging (MRI) to investigate the formation behaviour of gas voids within a gelled crude oil sample from a field in the South China Sea. Scanning of gelled crude at selected temperatures was performed following cooling in the circular pipe section within an experimental flow loop rig. Gas voids within the range of 7-12% were observed in the gelled samples resulted from different cooling temperatures and cooling rates. The cooling temperature and cooling rates were observed to influence significantly the location and volume of gas voids formed within the gelled samples. Higher cooling rates resulted in higher volume of gas voids close to pipe wall while lower cooling rates resulted in more gas voids located around core of the pipe.

Posted on: December 2014

Authored: Shaharin Anwar Sulaiman

One of the most challenging issues concerning the gasification of oil palm fronds (OPF) is the presence of tar and particulates formed during the process considering its high volatile matter content. In this study, a tar sampling train custom built based on standard tar sampling protocols was used to quantify the gravimetric concentration of tar (g/Nm3) in syngas produced from downdraft gasification of OPF. The amount of char, ash, and solid tar produced from the gasification process was measured in order to account for the mass and carbon conversion efficiency. Elemental analysis of the char and solid tar samples was done using ultimate analysis machine, while the relative concentration of the different compounds in the liquid tar was determined making use of a liquid gas chromatography (GC) unit. Average tar concentration of 4.928 g/Nm3 and 1.923 g/Nm3 was obtained for raw gas and cleaned gas samples, respectively. Tar concentration in the raw gas sample was found to be higher compared to results for other biomass materials, which could be attributed to the higher volatile matter percentage of OPF. Average cleaning efficiency of 61% which is comparable to that of sand bed filter and venturi scrubber cleaning systems reported in the literature was obtained for the cleaning system proposed in the current study.

Posted on: January 2014

Authored: Shaharin Anwar Sulaiman

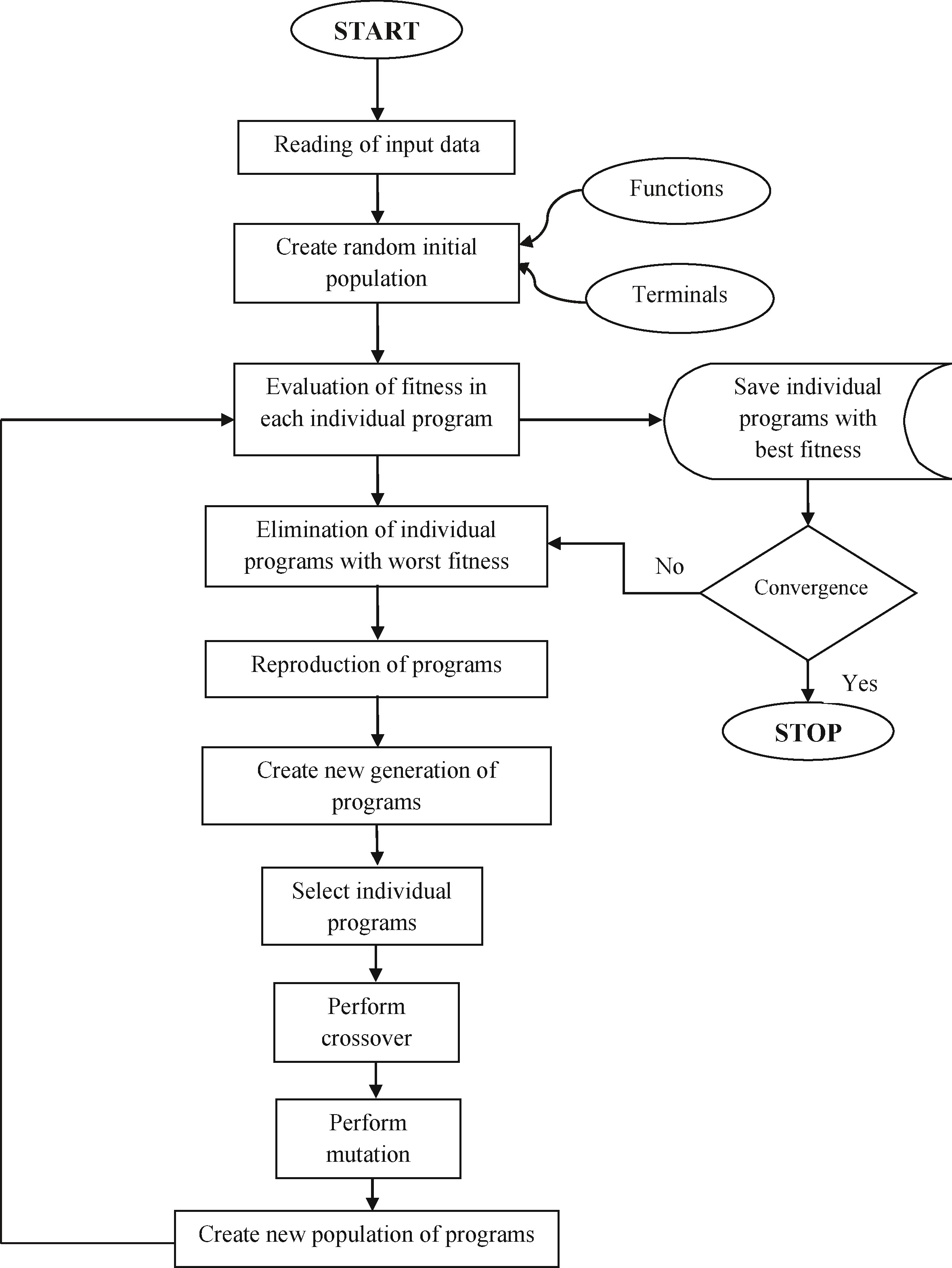

In oil and gas industry, the performance prediction of gas compressors is approaching criticality. Usually, maintenance engineers rely on recommendations set by the original equipment manufacturer (OEM) for maintenance activities. Since compressors are operated in offshore conditions, OEM recommendations may over predict or under predict the maintenance schedule. An improper verdict on compressor maintenance interventions may increase the equipment downtime because of unavailability of the resources and poor readiness of the spare parts. The aim of the presented research was to develop a diagnostic model for gas compressors by using the genetic programming (GP). The OEM isentropic and actual isentropic heads were compared, and the maintenance activity of a gas compressor was predicted by calculating the performance degradation. The computational codes were developed separately for OEM isentropic and actual isentropic heads through GP. Hereinafter, the empirical equations were derived from the developed computational codes to predict the optimum time for the routine maintenance. For rotational speed between the tested regions, GP predicted 92% accurate interpolation between the curves. It reveals that using the developed GP model, the operators can accurately predict the compressor's health and plan ahead the equipment maintenance at any time.

Posted on: September 2018

Authored: Shaharin Anwar Sulaiman

The main challenge on the fueling of pure hydrogen in the automotive vehicles is the limitation in the hydrogen separation from the product of steam reforming and gasification plants and the storage issues. On the other hand, hydrogen fueling in automotive engines has resulted in uncontrolled combustion. These are some of the factors which motivated for the fueling of raw syngas instead of further chemical or physical processes. However, fueling of syngas alone in the combustion chamber has resulted in decreased power output and increased in brake specific fuel consumption. Methane augmented hydrogen rich syngas was investigated experimentally to observe the behavior of the combustion with the variation of the fuel-air mixture and engine speed of a direct-injection spark-ignition (DI SI) engine. The molar ratio of the high hydrogen syngas is 50% H2 and 50% CO composition. The amount of methane used for augmentation was 20% (V/V). The compression ratio of 14:1 gas engine operating at full throttle position (the throttle is fully opened) with the start of the injection selected to simulate the partial DI (180° before top dead center (BTDC)). The relative air-fuel ratio (λ) was set at lean mixture condition and the engine speed ranging from 1500 to 2400 revolutions per minute (rpm) with an interval of 300 rpm. The result indicated that coefficient of variation of the indicate mean effective pressure (COV of IMEP) was observed to increase with an increase with λ in all speeds. The durations of the flame development and rapid burning stages of the combustion has increased with an increase in λ. Besides, all the combustion durations are shown to be more sensitive to λ at the lowest speed as compared to the two engine speeds.

Posted on: January 2019

Authored: Shaharin Anwar Sulaiman

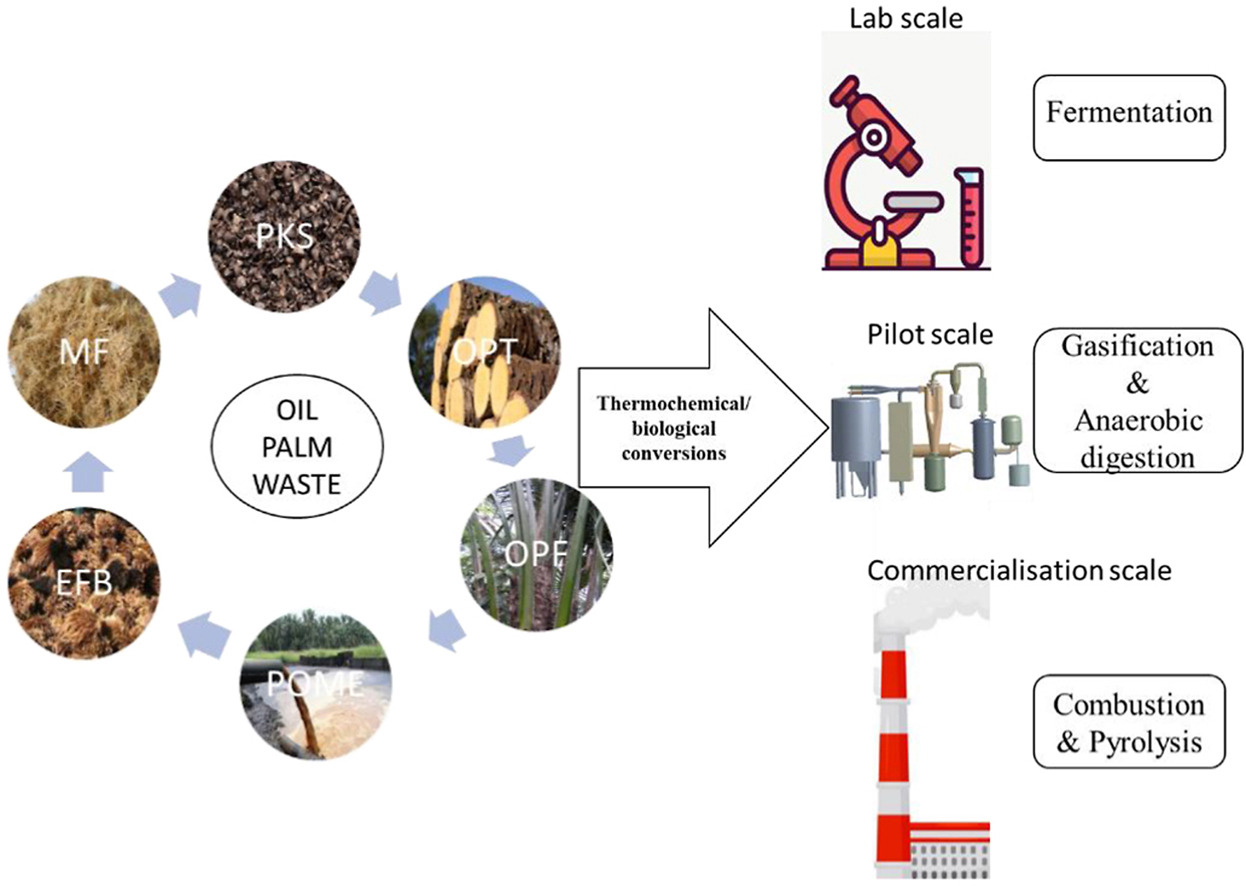

The conversion of oil palm waste to valuable fuels via biological and thermochemical means has witnessed much interest from researchers. Increasing tonnes of palm waste resulting from about 400 palm oil mills across Malaysia necessitates a rethink towards its conversion to energy to curb soil and air pollution, underground water contamination, and pest habitats. Converting these palm wastes to fuel at a commercial scale is necessary to advance Malaysia's bioenergy. This will ensure cleaner production and sustainability by providing low carbon energy that could be used in industrial, transport, and residential sectors. However, what is the technology readiness levels of these conversion methods in Malaysia? Have they reached commercialisation? What hinders them from attaining it? This study conducted an intensive literature review on five conversion technologies broadly classified as thermochemical (combustion, gasification and pyrolysis) and biological (anaerobic digestion and fermentation) to identify the extent to which each process has been adopted. For each of the technologies, the following were established: (1) Studies conducted by researchers using different palm wastes; (2) Challenges faced; (3) Technology readiness level. The significant findings revealed that fermentation is still at a lab scale, gasification and anaerobic digestion have reached pilot-scale while combustion and pyrolysis have attained commercialisation. Significant commercialisation challenges include technical and economic issues, communal consciousness, and stakeholder gap. Current research gaps, recommendations, future outlooks, and the way forward were discussed, along with developing a framework that features the key barriers, enablers, and stakeholders responsible for commercialisation.

Posted on: August 2021

Authored: Shaharin Anwar Sulaiman