Study on Tar Generated from Downdraft Gasification of Oil Palm Fronds

Author: Shaharin Anwar Sulaiman - January 2014

Abstract

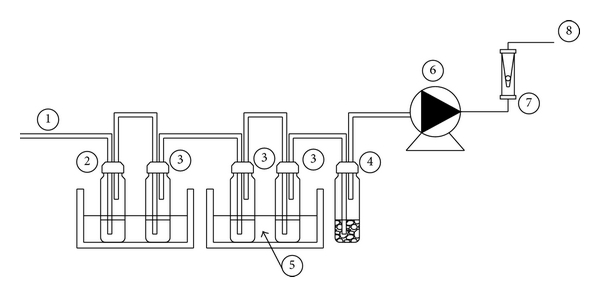

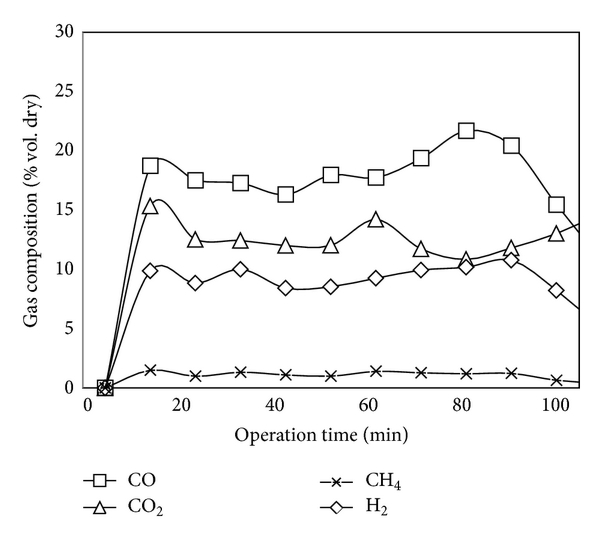

One of the most challenging issues concerning the gasification of oil palm fronds (OPF) is the presence of tar and particulates formed during the process considering its high volatile matter content. In this study, a tar sampling train custom built based on standard tar sampling protocols was used to quantify the gravimetric concentration of tar (g/Nm³) in syngas produced from downdraft gasification of OPF. The amount of char, ash, and solid tar produced from the gasification process was measured in order to account for the mass and carbon conversion efficiency. Elemental analysis of the char and solid tar samples was done using ultimate analysis machine, while the relative concentration of the different compounds in the liquid tar was determined making use of a liquid gas chromatography (GC) unit. Average tar concentration of 4.928 g/Nm³ and 1.923 g/Nm³ was obtained for raw gas and cleaned gas samples, respectively. Tar concentration in the raw gas sample was found to be higher compared to results for other biomass materials, which could be attributed to the higher volatile matter percentage of OPF. Average cleaning efficiency of 61% which is comparable to that of sand bed filter and venturi scrubber cleaning systems reported in the literature was obtained for the cleaning system proposed in the current study.

Methodology

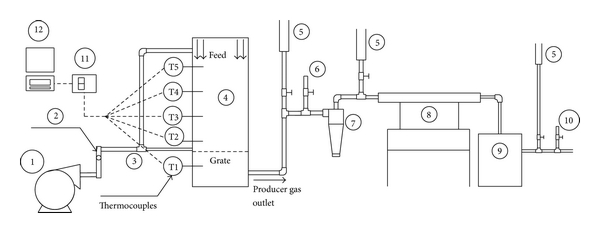

The gasifier used for the experiment was a laboratory-scale stationary, batch-operated 50 kW fixed-bed downdraft gasifier. The schematic of the experimental setup is shown in Figure 3. Atmospheric air was supplied into the gasifier using a 250 W vortex blower and the amount of air supplied was controlled using a ball valve and a bypass point and monitored using a Pitot tube and a water manometer. The downdraft gasification of OPF was conducted controlling the inlet air flow into the gasifier at an average value of 200 lpm that keep the reactor temperature in between 700 and 900°C. Various syngas conditioning units were provided downstream of the gasifier for the cooling and cleaning of syngas, which include a cyclone (7), cooling heat exchanger (8), and oil bath filter (9) which were provided before the cleaned gas sampling point (10). In addition, as shown in Figure 3, a number of gas flare points (5) were provided on the outlet piping in order to check the combustibility of produced syngas and to burn poisonous gases like CO before being released to the atmosphere.

Impact & Benefits

Environmental Impact: Understanding the composition and quantity of tar produced during gasification helps in assessing its environmental impact. Tar can contain harmful compounds such as polycyclic aromatic hydrocarbons (PAHs), which are carcinogenic and can contribute to air pollution if released into the atmosphere. By studying tar, researchers can develop strategies to minimize its formation or devise effective methods for its removal, thereby reducing environmental pollution.

Energy Efficiency: Tar formation during gasification can lead to equipment fouling and reduce the efficiency of the gasification process. By studying the characteristics of tar, researchers can optimize gasification conditions to minimize tar production, thereby improving the overall energy efficiency of the process.

Product Quality: Tar can be detrimental to the quality of the syngas produced during gasification, affecting its calorific value and usability for various applications such as power generation or synthesis of chemicals. Understanding tar composition and behavior allows researchers to tailor gasification parameters to produce syngas with desired quality characteristics, enhancing its value as a renewable energy source or feedstock for other processes.

Economic Viability: Tar removal and cleanup processes can incur additional costs in gasification systems. By studying tar formation and properties, researchers can develop cost-effective methods for tar removal or mitigation, thereby improving the economic viability of gasification as a renewable energy technology.

Market Potential

Energy Sector Demand: There's a growing global demand for renewable energy sources due to increasing concerns about climate change and the depletion of fossil fuels. Studies on tar generated from gasification of oil palm fronds can contribute to the development of more efficient and sustainable bioenergy technologies, thus addressing this demand.

Regulatory Environment: Government policies and regulations aimed at promoting renewable energy and reducing greenhouse gas emissions can significantly influence the market potential for studies in this field. Supportive policies such as renewable energy targets, feed-in tariffs, carbon pricing mechanisms, and emission reduction mandates can create a favorable market environment for bioenergy research and development.

Technological Advancements: Advances in gasification technology, tar removal techniques, and syngas cleanup processes can enhance the market potential for studies on tar generated from oil palm fronds gasification. Innovations that improve the efficiency, reliability, and cost-effectiveness of gasification systems can drive market adoption.

Industry Interest and Investment: The interest and investment from industry players, including energy companies, technology providers, and research institutions, play a crucial role in shaping the market potential for such studies. Collaborations between academia, government, and private sector entities can accelerate research progress and commercialization efforts.