Research Success Stories

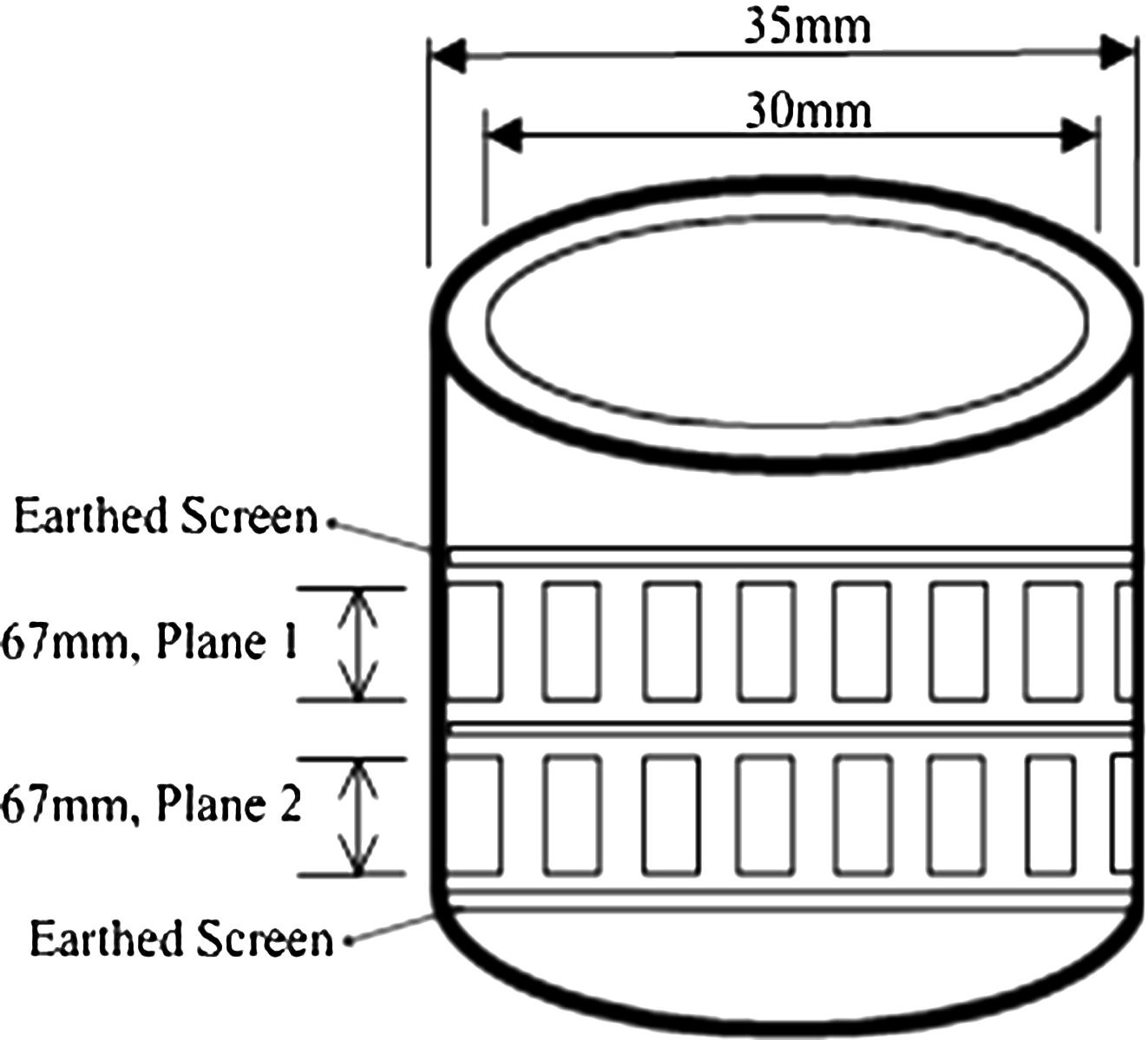

Waxy crude oil is one of the massively produced petroleum reserves in the oil and gas industry. It possesses two different natures at different conditions. At a temperature above its wax appearance temperature it functions as a Newtonian fluid. Moreover, when it flows in a subsea environment where the temperature drops, the occurrence of non-Newtonian fluid would appear. However, it is mandatory to prevent the pipelines from building up with the solid wax layer, or else a strong paraffinic gel structure would plug the flow of the waxy crude oil. This gel accumulation results in the emergence of thermal shrinkage where gas voids consequently occur. A Malay Basin waxy crude oil has used for this study to investigate the gas void formation in statically cooled waxy crude oil using an online Electrical Capacitance Tomography (ECT) measurement. This paper has been focused on the development of a non-invasive, non-intrusive approach for the visualization of waxy crude oil by applying the ECT system. The online inspection of the behavior of waxy crude oil is important so that the appropriate action can be taken during the gas void formation within a gelled crude oil. An experimental study was conducted on a 1.18in. circular flow loop rig at distinct temperatures to assess the behavior and formation of gas voids formed due to thermal shrinkage. A capacitance sensor with dual planes consisting of eight electrodes per plane was installed on the rig to capture the images and measure the raw capacitance. Gas voids within a range of 8-14% were observed within the gelled crude oil based on different cooling temperatures. It has been found from the analysis that the gas voids follow an increasing trend with a decrease in temperature and cooling rate.

Posted on: October 2015

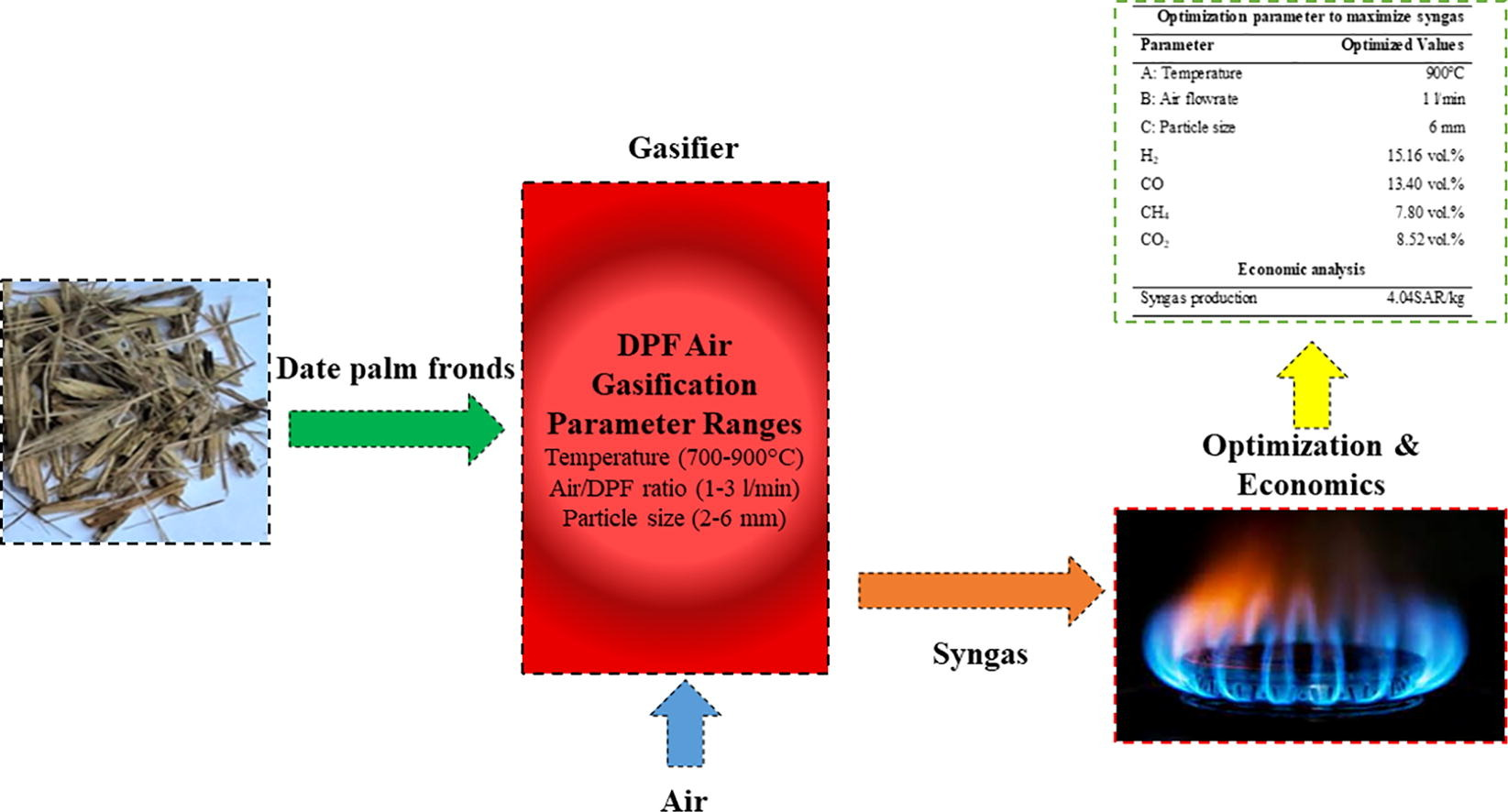

Authored: Shaharin Anwar Sulaiman

The transition of energy extraction from the fossil fuel to renewable energy is a primary drive-in world. Saudi Arabia is one of the big producer of date fruit which generates an abundant amount of date palm wastes. There is no proper utilization of these wastes in Saudi Arabia. Conversion of date palm waste into energy is a major potential alternative source of bioenergy via gasification. In current study, process optimization and economic evaluation of air gasification of date palm fronds (DPF) has been performed in downdraft gasifier for energy conversion. The impact of three process parameters temperature, air flowrate, and feedstock particle size on gas composition were investigated. The response surface methodology (RSM) was adopted for experimental design, optimization, and individual and interactive effects of parameters on H2 and CO compositions to find their optimum values. Temperature is the most influencing factor for H2 composition and it varies from 6 vol% to 18 vol% which is higher compared to air flowrate and feedstock particle size. A similar pattern of influencing factors was observed for CO composition it varies from 8 vol% to 20 vol%. The enrichment of H2 and CO is due to the activation of endothermic reactions at elevated temperature. On the other hand, factor influencing order for CO2 composition as feedstock particle size > air flowrate > temperature. The optimum conditions were found 900°C temperature, 1 l/min air flowrate, and 6 mm feedstock particle size to maximizing the H2 and CO compositions. Cost of syngas produced from air gasification of DPF was determined SAR 4.04/kg which can be minimized to scale-up the gasification system. DPF conversion into energy is environmentally friendly alternative source of renewable energy that will helps to reduce the dependency on fossil fuel.

Posted on: May 2022

Authored: Shaharin Anwar Sulaiman

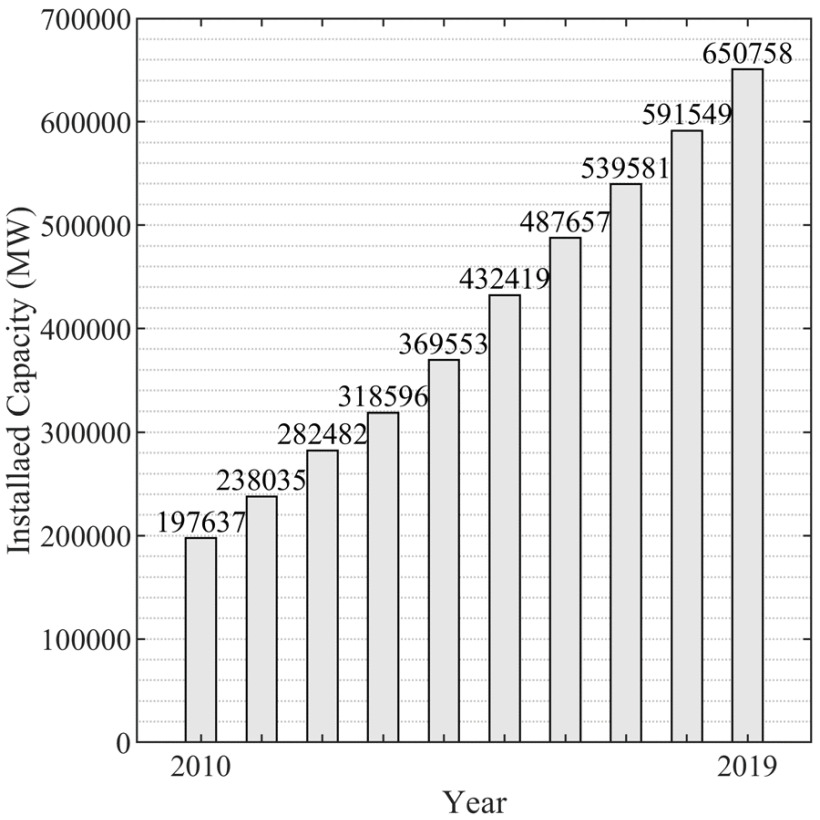

Wind speed forecasts can boost the quality of wind energy generation by increasing the efficiency and enhancing the economic viability of this variable renewable resource. This work proposes a hybrid model for wind energy capacity for electrical power generation at coastal sites by utilizing wind-related variables' characteristics. The datasets of three coastal locations of Kuwait validate the proposed method. The hybrid model is a merger of Artificial Neural Network (ANN) and Particle Swarm Optimization (PSO) and predicts one-month-ahead wind speed for wind power density calculation. The neural network starts its performance evaluation with a variable number of hidden-layer neurons to finally identify the optimal ANN topology. Comparisons of statistical indices with both expected and observed test results indicate that the ANN-PSO based hybrid model with the low root-mean-square-error and mean-square-error values outperforms ANN-based trivial models. The prediction model developed in this work is highly accurate with a Mean Absolute Percentage Error (MAPE) of approximately (3-6%) for all the sites.

Posted on: January 2020

Authored: Shaharin Anwar Sulaiman

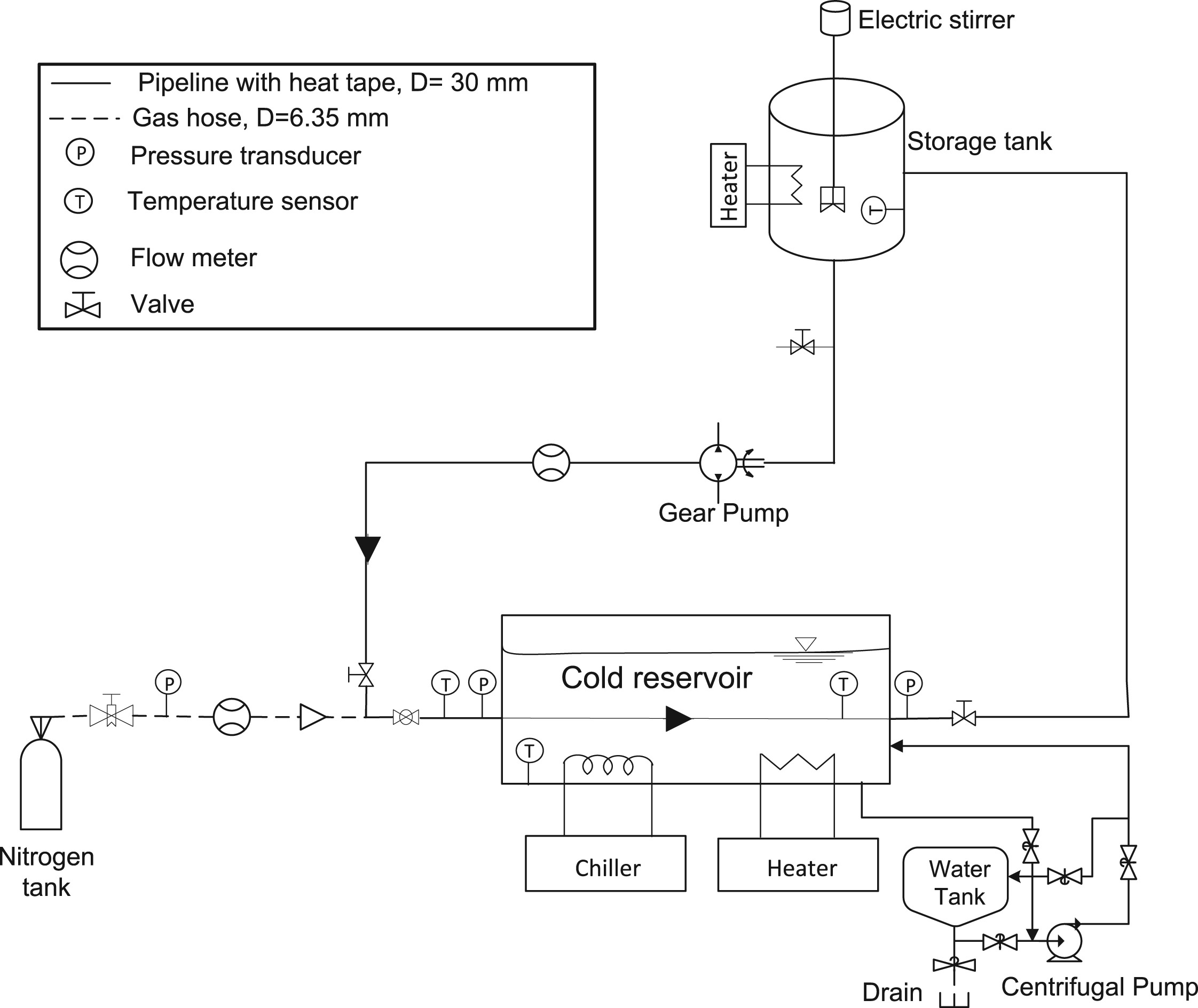

Wax deposition in production pipelines causes flow assurance issue due to reduction in flow rate. Gelling of waxy crude oil after subsequent cooling restricts the flow and causes blockage in pipelines, and thus requiring large and costly pumps to restart and regain the steady flow. Nevertheless, the formation of intra-gel voids in the gel was recently reported to ease restart pumping. Further, it is believed that injecting non-reacting gas into the production lines prior to or during shut down could alleviate the restart flow problem and save costs. An experimental work was conducted in order to manipulate the effectiveness of such approach. A flow loop rig was used to simulate the conditions of waxy crude oil in pipelines on seabed and a gas injection system was used to inject nitrogen into the system after crude oil stopped flowing, prior to gelation process. Restart pressure was applied in two modes: instantaneous and gradual pumping. It was observed that maximum restart pressure reductions of 11.48% and 17.44% were achieved when pressure was applied instantaneously and gradually, respectively. It was found that the restart pressure decreased as the gas to oil volume ratio increased due to high slippage effect. In addition, restart pressure under gradual restart approach was observed to be higher than that for instantaneous restart approach.

Posted on: April 2017

Authored: Shaharin Anwar Sulaiman

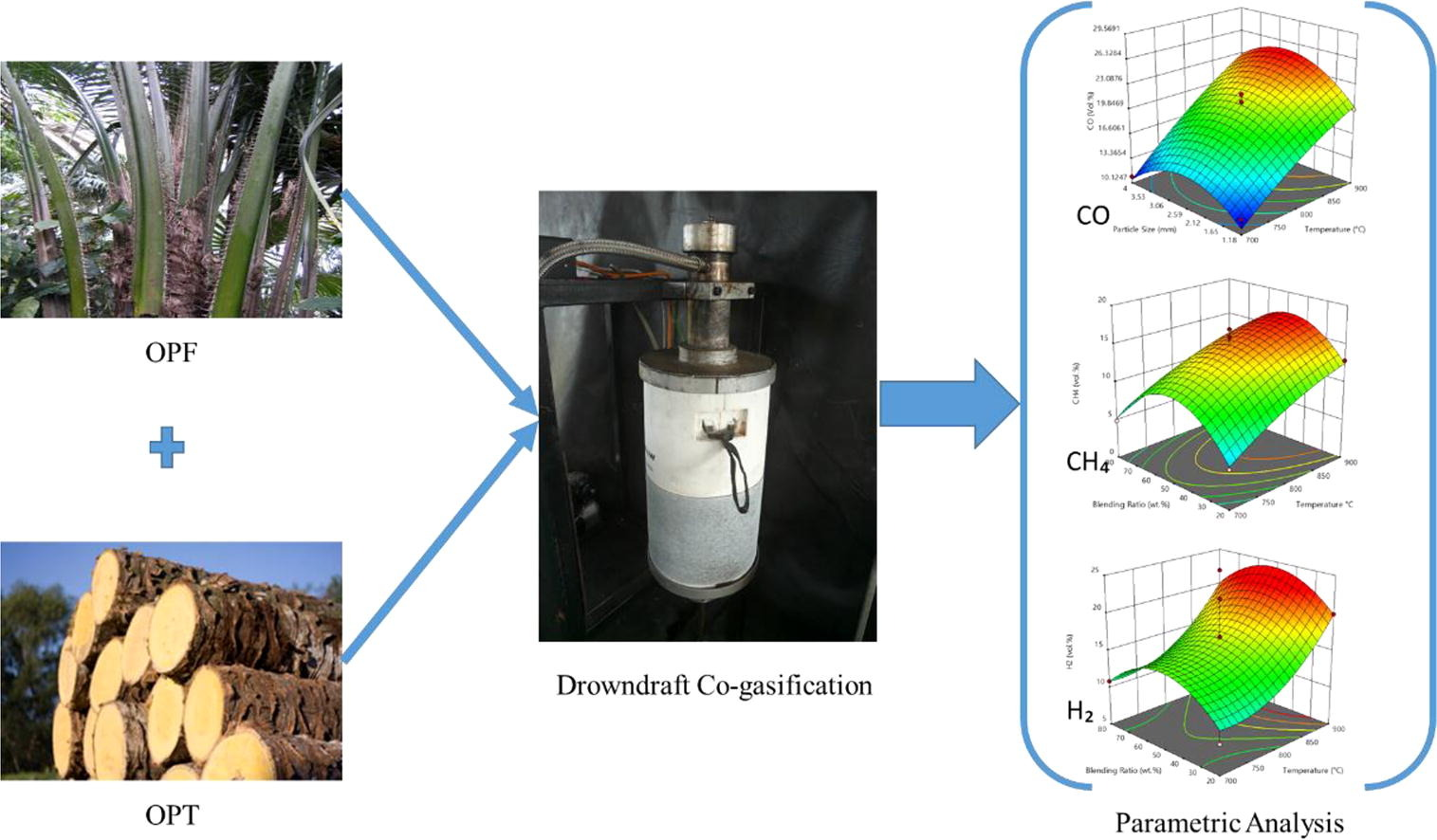

Biomass co-gasification is among the most encouraging bio-conversion technologies used in the production of clean and sustainable fuel. This research work was performed on the co-gasification of oil palm trunk and frond to explore the mutual relation of input variables on syngas and optimize them for maximum syngas generation. Air was utilised as the agent of gasification, while a downdraft gratifier was used as the reactor. The operating variables are temperature (700-900°C), blending ratio (20-80 wt%) and particle size (1.18-4 mm). Optimization was achieved through Response Surface Methodology, Box-Behnken design. The results showed that the operating variables influenced the results in increasing order of temperature, particle size, and blending ratio. Optimum syngas composition was obtained as 20.22 vol% H2, 24.86 vol% CO, and 13.78 vol% CH4 at a temperature of 900°C, particle size of 2.59 mm and a blending ratio of 20OPT:80OPF.The optimized values resulted in a high syngas yield and co-gasification performance. Cost analysis of the optimum blend was carried out, and it was found that the operating cost played a significant role in the final syngas cost. It occupied about 49% of the production cost, while the capital and other cost occupied occupy 44% and 7% respectively.

Posted on: February 2022

Authored: Shaharin Anwar Sulaiman