Estimation of gas void formation in statically cooled waxy crude oil using online capacitance measurement

Author: Shaharin Anwar Sulaiman - October 2015

Abstract

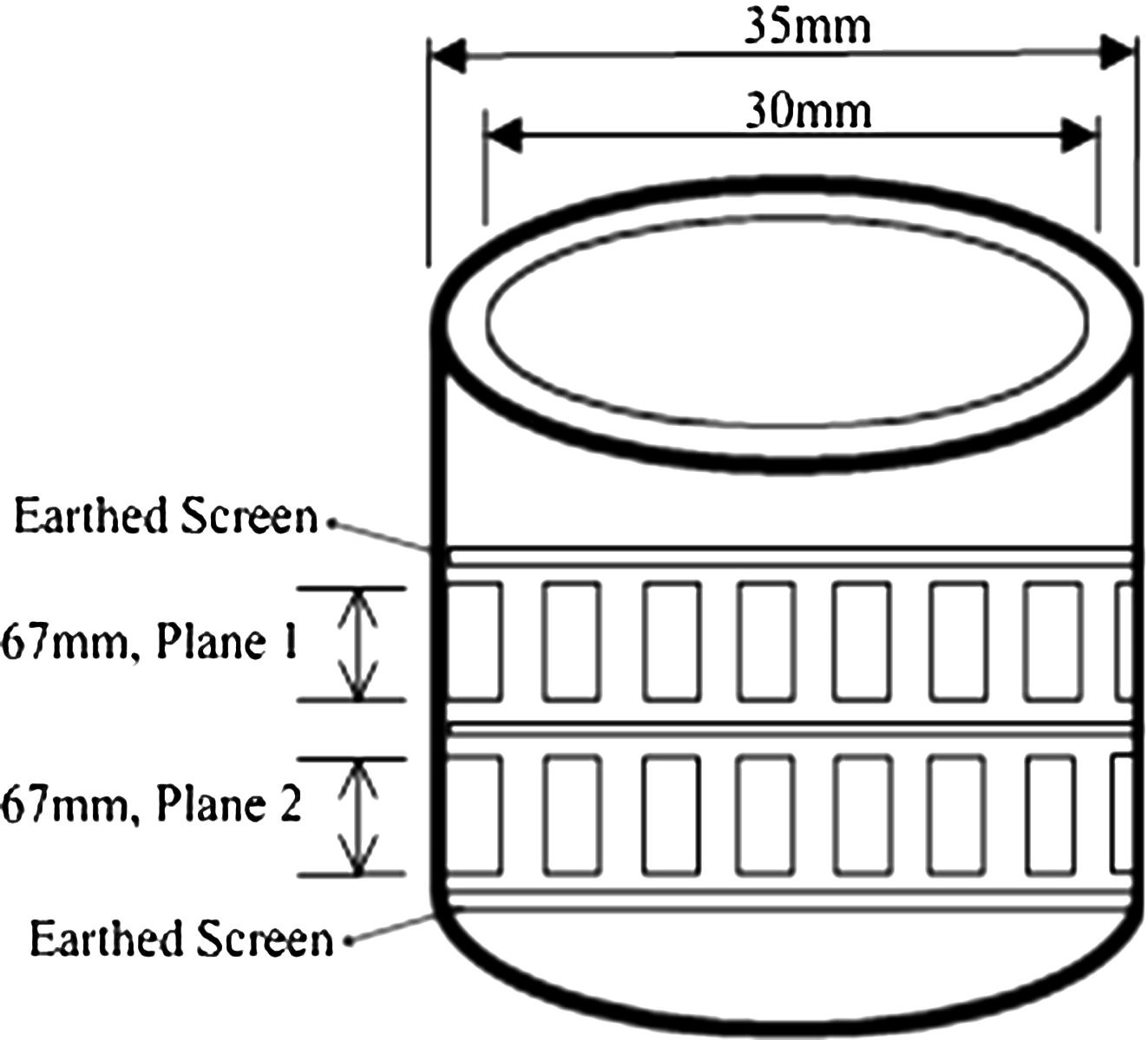

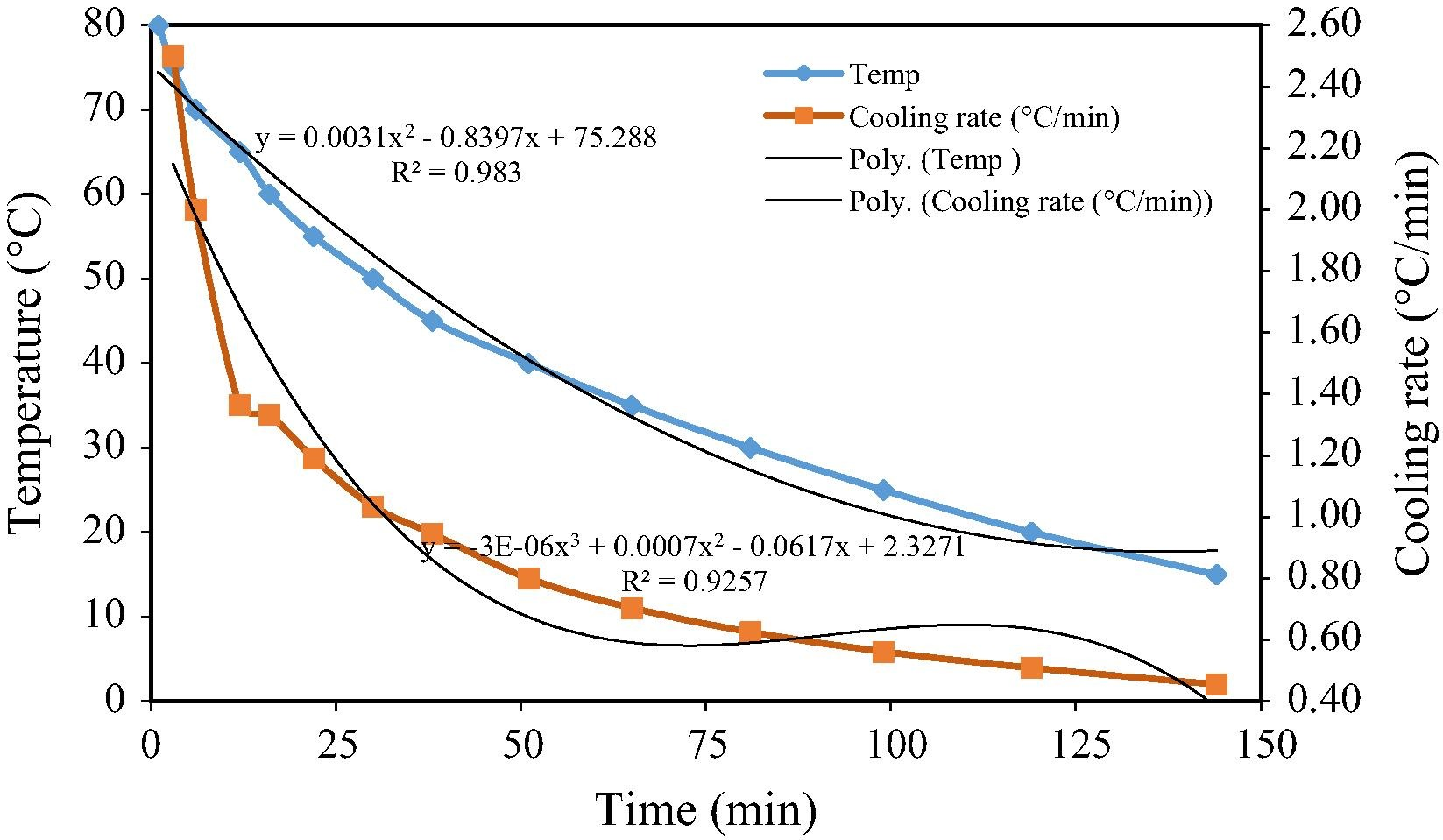

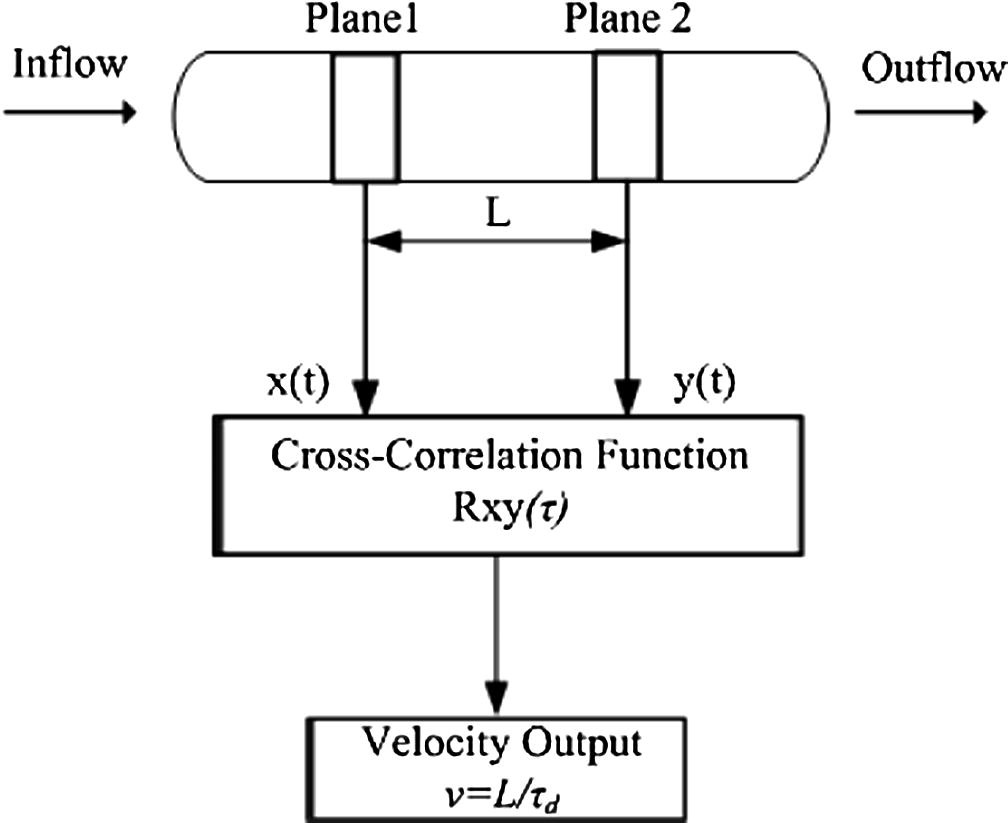

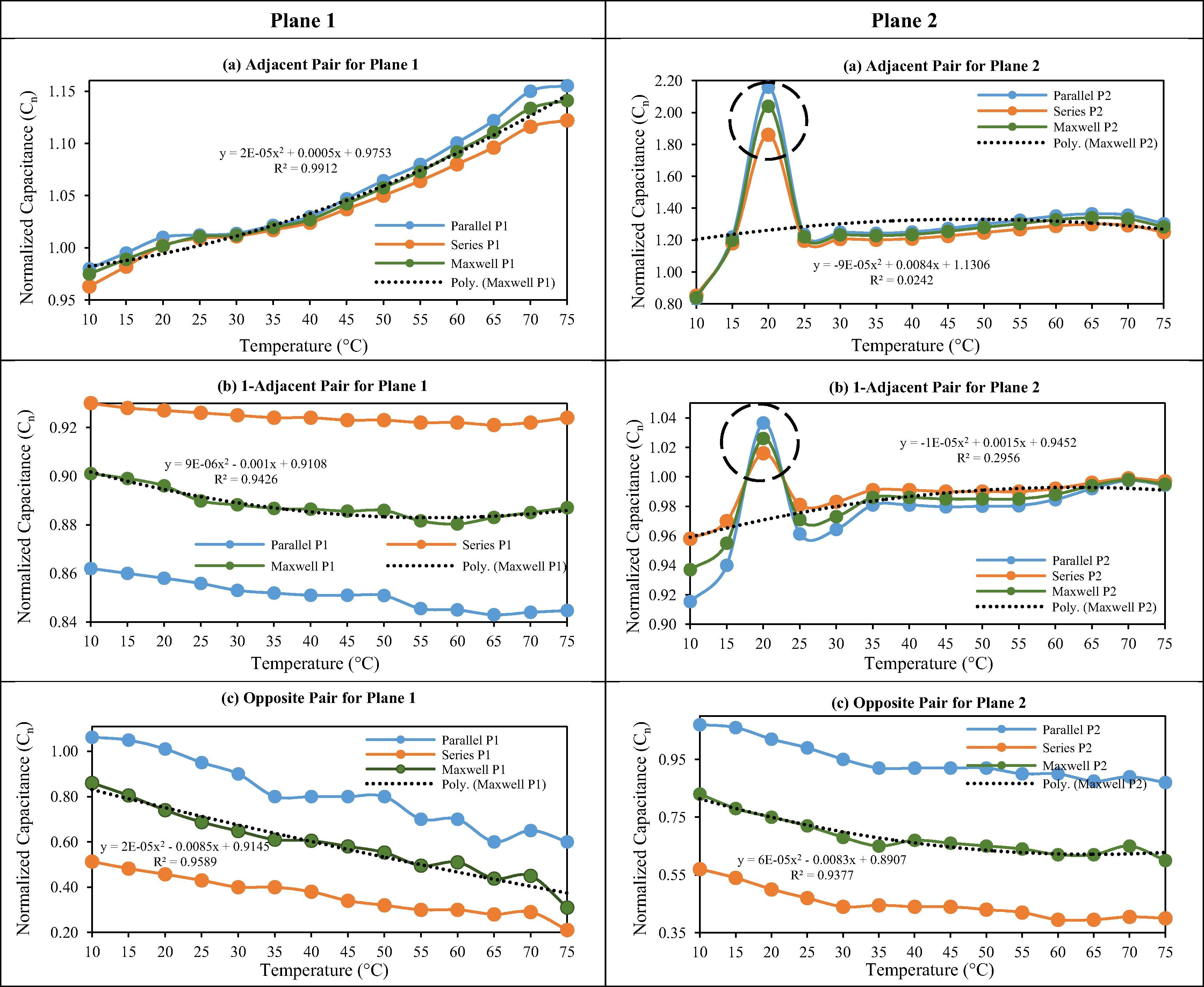

Waxy crude oil is one of the massively produced petroleum reserves in the oil and gas industry. It possesses two different natures at different conditions. At a temperature above its wax appearance temperature it functions as a Newtonian fluid. Moreover, when it flows in a subsea environment where the temperature drops, the occurrence of non-Newtonian fluid would appear. However, it is mandatory to prevent the pipelines from building up with the solid wax layer, or else a strong paraffinic gel structure would plug the flow of the waxy crude oil. This gel accumulation results in the emergence of thermal shrinkage where gas voids consequently occur. A Malay Basin waxy crude oil has used for this study to investigate the gas void formation in statically cooled waxy crude oil using an online Electrical Capacitance Tomography (ECT) measurement. This paper has been focused on the development of a non-invasive, non-intrusive approach for the visualization of waxy crude oil by applying the ECT system. The online inspection of the behavior of waxy crude oil is important so that the appropriate action can be taken during the gas void formation within a gelled crude oil. An experimental study was conducted on a 1.18in. circular flow loop rig at distinct temperatures to assess the behavior and formation of gas voids formed due to thermal shrinkage. A capacitance sensor with dual planes consisting of eight electrodes per plane was installed on the rig to capture the images and measure the raw capacitance. Gas voids within a range of 8-14% were observed within the gelled crude oil based on different cooling temperatures. It has been found from the analysis that the gas voids follow an increasing trend with a decrease in temperature and cooling rate.

Methodology

An appropriate experimental procedure is crucial for reliable experiments. The study found that long-term preservation of this crude oil causes it to split into heavier and lighter parts due to density differences. To prepare for the experiment, the wax inside the flow loop was dissolved by running the trace element heater and crude oil tank heater at temperatures above its WAT. This ensured a homogeneous temperature distribution before initiating the flow. Once the crude oil flowed smoothly through the test section, the inlet and outlet valves were closed for static cooling. Chilled water was then used to cool the waxy crude oil, and measurements were taken using a dual plane ECT sensor. Data collection included raw capacitance, ECT tomogram images, and cooling time recorded for every 5°C change in temperature. After the experiment, the test section was drained, the ECT sensor cleaned, and the data files saved for further analysis.

Impact & Benefits

Improved Safety: Gas void formation in crude oil can lead to hazardous conditions such as gas pockets or even explosions during handling, transportation, or storage. Online capacitance measurement allows for real-time monitoring, enabling early detection and mitigation of potential safety risks.

Enhanced Process Control: By continuously monitoring gas void formation, operators can adjust process parameters to optimize production and prevent operational disruptions. This ensures consistent quality and efficiency in crude oil processing operations.

Cost Savings: Early detection of gas void formation can prevent equipment damage and downtime, leading to cost savings associated with maintenance, repairs, and production losses. Additionally, optimized process control can result in improved yield and reduced energy consumption.

Environmental Protection: Gas void formation can contribute to environmental pollution if not properly managed. By accurately estimating gas voids in crude oil, operators can implement measures to minimize emissions and ensure compliance with environmental regulations.

Market Potential

Technological Advancements: Advances in sensor technology, data analytics, and automation have made online capacitance measurement systems more reliable, accurate, and cost-effective. These advancements have expanded the market potential for such systems, making them viable options for a wide range of applications in the oil and gas industry.

Operational Efficiency: Operators are continuously seeking ways to improve operational efficiency and reduce costs. Online capacitance measurement systems offer real-time monitoring capabilities that enable proactive maintenance, optimized process control, and efficient resource allocation. This value proposition drives demand for these systems among oil and gas companies looking to enhance productivity and profitability.

Market Expansion: The market potential for online capacitance measurement systems is not limited to the oil and gas industry. Other industries, such as petrochemicals, power generation, and wastewater treatment, also utilize similar processes involving fluid handling and storage, presenting additional opportunities for market expansion and growth.

Global Reach: The market potential for estimation of gas void formation using online capacitance measurement extends globally, as waxy crude oil reserves are found in various regions worldwide. This global reach ensures a broad customer base and diverse market opportunities for technology providers.