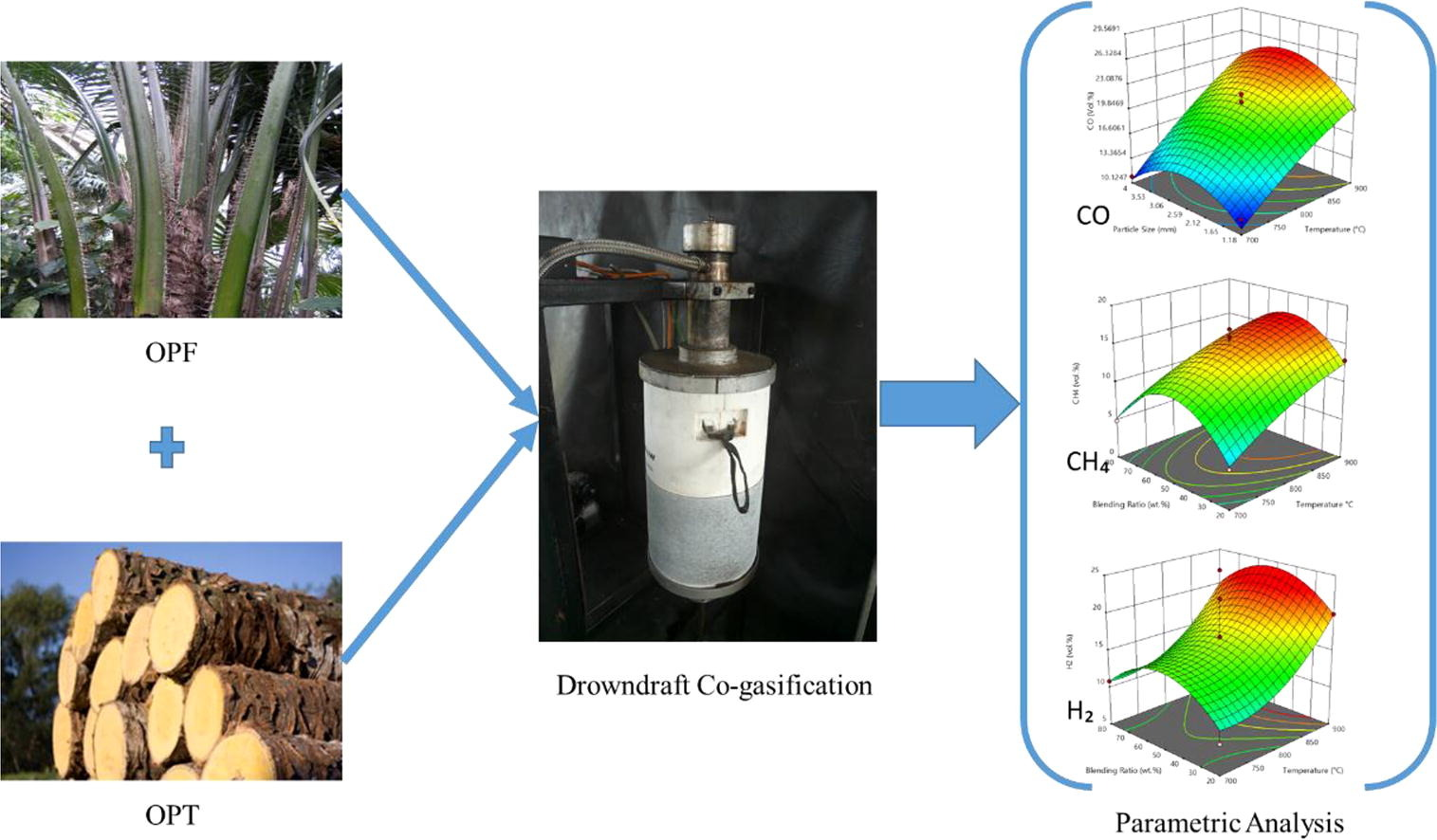

Parametric optimisation through the use of Box-Behnken design in the Co-gasification of oil palm trunk and frond for syngas production

Author: Shaharin Anwar Sulaiman - February 2022

Abstract

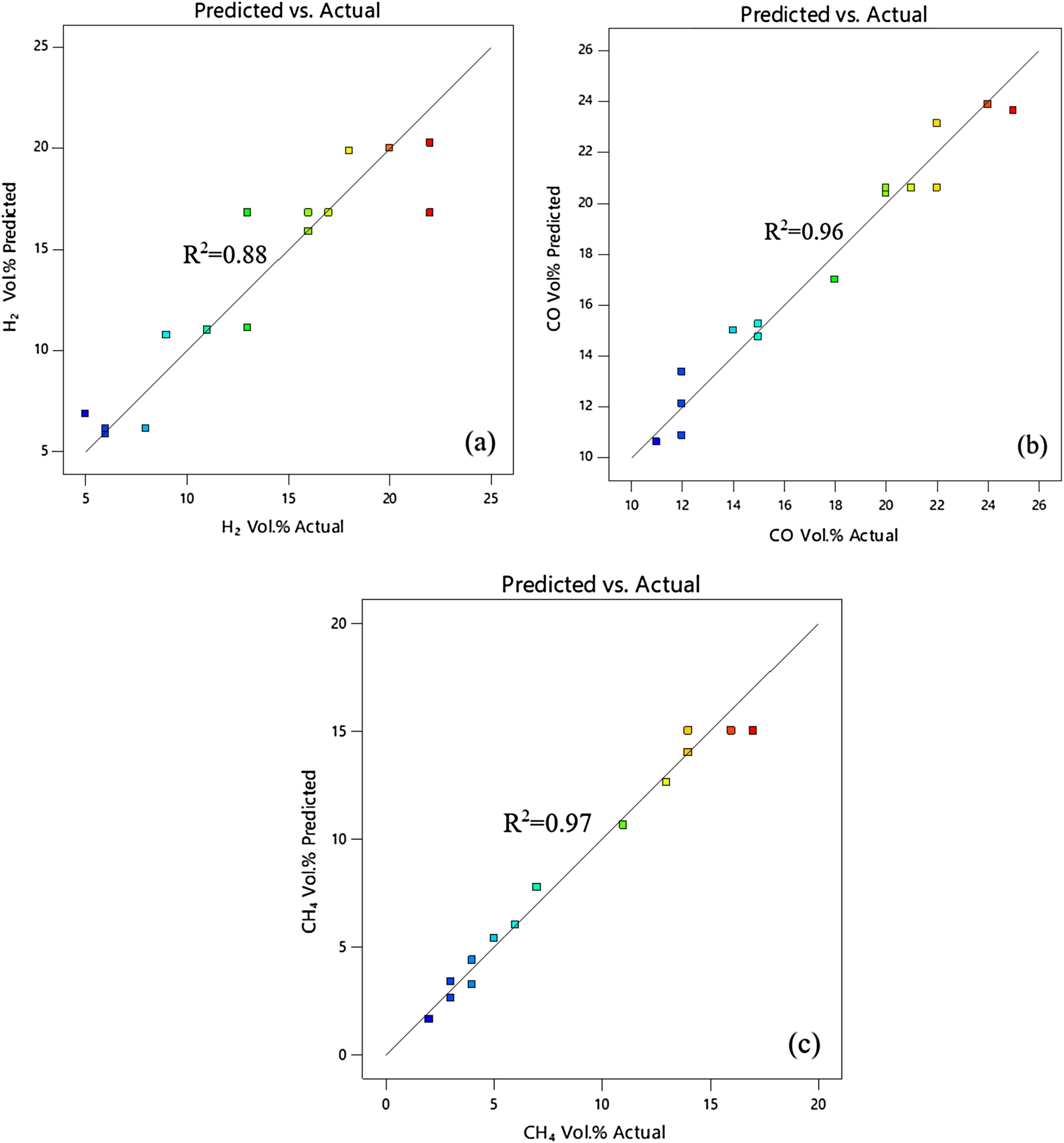

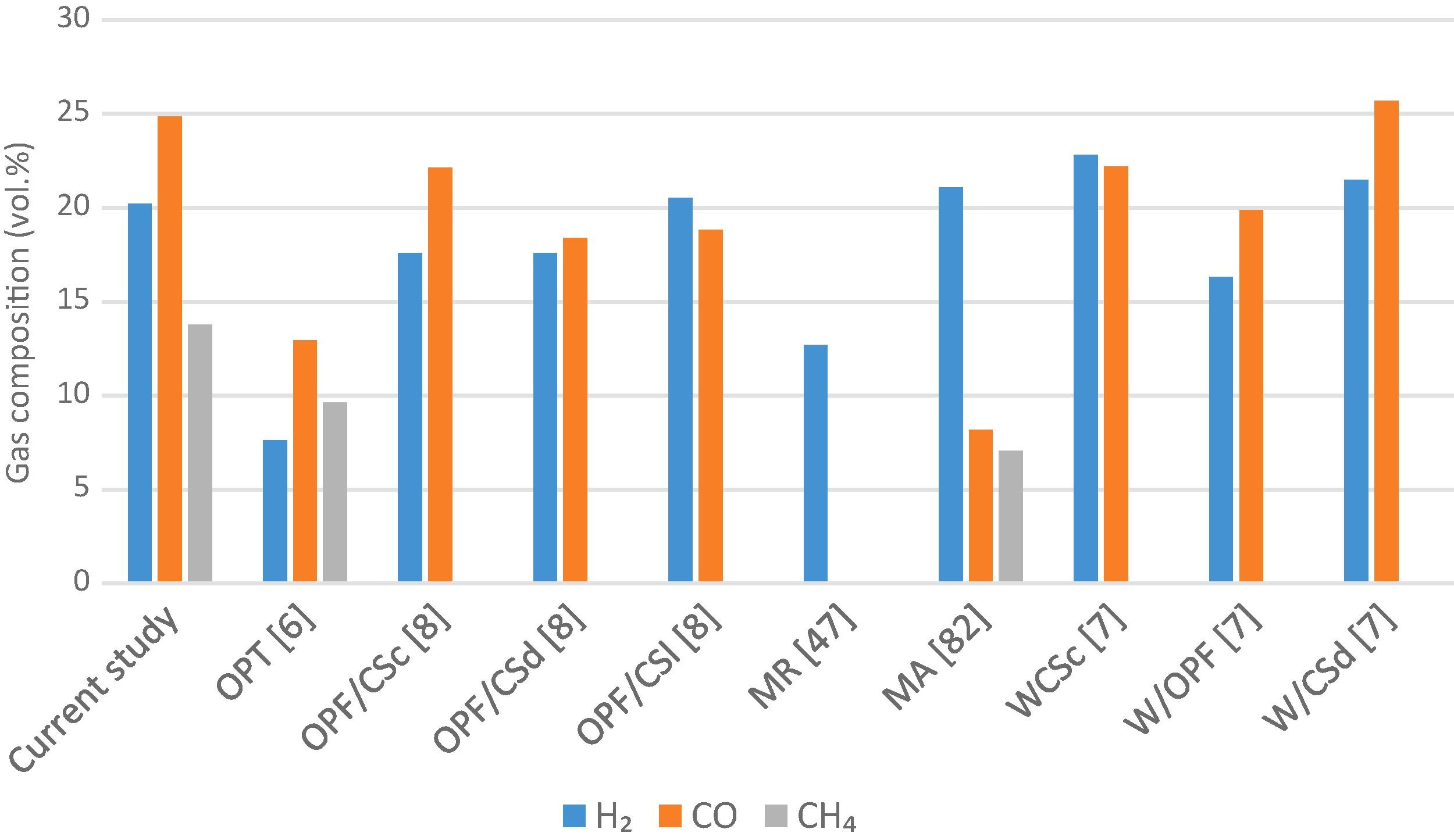

Biomass co-gasification is among the most encouraging bio-conversion technologies used in the production of clean and sustainable fuel. This research work was performed on the co-gasification of oil palm trunk and frond to explore the mutual relation of input variables on syngas and optimize them for maximum syngas generation. Air was utilised as the agent of gasification, while a downdraft gratifier was used as the reactor. The operating variables are temperature (700-900°C), blending ratio (20-80 wt%) and particle size (1.18-4 mm). Optimization was achieved through Response Surface Methodology, Box-Behnken design. The results showed that the operating variables influenced the results in increasing order of temperature, particle size, and blending ratio. Optimum syngas composition was obtained as 20.22 vol% H2, 24.86 vol% CO, and 13.78 vol% CH4 at a temperature of 900°C, particle size of 2.59 mm and a blending ratio of 20OPT:80OPF.The optimized values resulted in a high syngas yield and co-gasification performance. Cost analysis of the optimum blend was carried out, and it was found that the operating cost played a significant role in the final syngas cost. It occupied about 49% of the production cost, while the capital and other cost occupied occupy 44% and 7% respectively.

Methodology

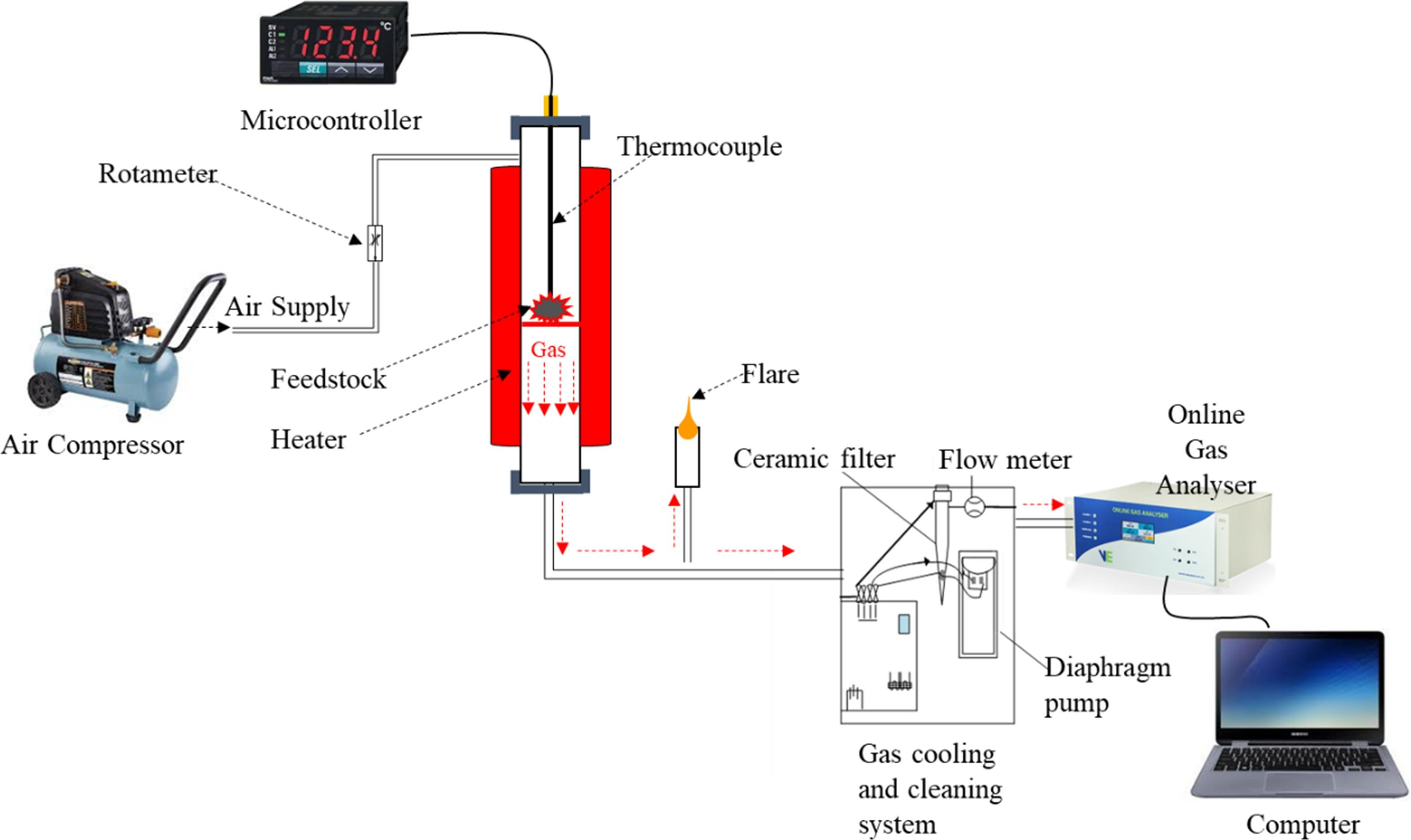

The set-up used for the study is shown in Fig. 1. It consists of a gasifier, a cylindrical metallic body encased in a ceramic electric heater. The gasifier is connected to a microcontroller from which the temperature settings are managed. An air compressor is also connected to the system for air supply, which is controlled with a rotameter. At the beginning of the experiment, the gasifier was switched on and gradually heated up by continually adjusting the temperature controller. When the desired temperature was reached, air at 2.5 L/min was supplied to the gasifier. Afterwards, the gasifier's lid was opened, and premixed biomass was poured and instantly closed swiftly. The produced gas moved through the bottom of the gasifier through a pipe and travelled through the gas cooling and cleaning unit to the online analyzer. The analyzed gas was displayed on the computer monitor connected to the analyzer via LAN intranet cable. Readings were automatically recorded every second and saved. The gasifier was switched off and cooled for charcoal and ash removal. Table 4 gives the principal measuring instruments' specifications, including their range, accuracy, and type, among others.

Impact & Benefits

Efficient Parameter Optimization: Box-Behnken design allows for efficient optimization of multiple parameters simultaneously, such as temperature, pressure, residence time, and feedstock composition. By systematically varying these parameters within predetermined ranges, researchers can identify the optimal conditions for maximizing syngas production.

Reduced Experimental Effort: Box-Behnken design requires fewer experiments compared to full factorial designs, thereby reducing experimental time, cost, and resources. This efficiency is particularly advantageous in complex processes like co-gasification, where numerous parameters interact with each other.

Improved Syngas Yield and Quality: Through parametric optimization, researchers can enhance the yield and quality of syngas produced from oil palm trunk and frond co-gasification. This can involve maximizing the concentrations of desired syngas components (such as hydrogen and carbon monoxide) while minimizing undesired by-products (such as tar and char).

Insight into Process Dynamics: By systematically varying parameters, Box-Behnken design provides insights into the complex dynamics of co-gasification processes. Researchers can gain a deeper understanding of how different factors influence syngas production and identify potential mechanisms for optimization.

Market Potential

Renewable Energy Demand: With growing concerns about climate change and the depletion of fossil fuel reserves, there is a rising demand for renewable energy sources. Syngas produced from biomass through co-gasification presents a promising avenue for meeting this demand, particularly in sectors such as power generation, heat production, and industrial processes.

Policy Support and Incentives: Government policies and incentives aimed at promoting renewable energy and reducing greenhouse gas emissions can significantly drive the market potential for co-gasification technology. Subsidies, tax credits, renewable energy mandates, and carbon pricing mechanisms can enhance the competitiveness of syngas produced from biomass.

Technological Advancements: Advances in co-gasification technology, including parametric optimization techniques like Box-Behnken design, contribute to improving the efficiency, scalability, and cost-effectiveness of syngas production. As these technologies mature and become more accessible, they enhance the market potential by offering reliable and competitive alternatives to conventional fossil fuels.

Environmental Concern: Growing awareness of environmental issues, such as air pollution and carbon emissions, drives the demand for cleaner and sustainable energy solutions. Co-gasification of oil palm trunk and frond offers environmental benefits by utilizing renewable biomass resources and reducing emissions compared to fossil fuel combustion, thereby increasing its market potential.