Process optimization and economic evaluation of air gasification of Saudi Arabian date palm fronds for H2-rich syngas using response surface methodology

Author: Shaharin Anwar Sulaiman - May 2020

Abstract

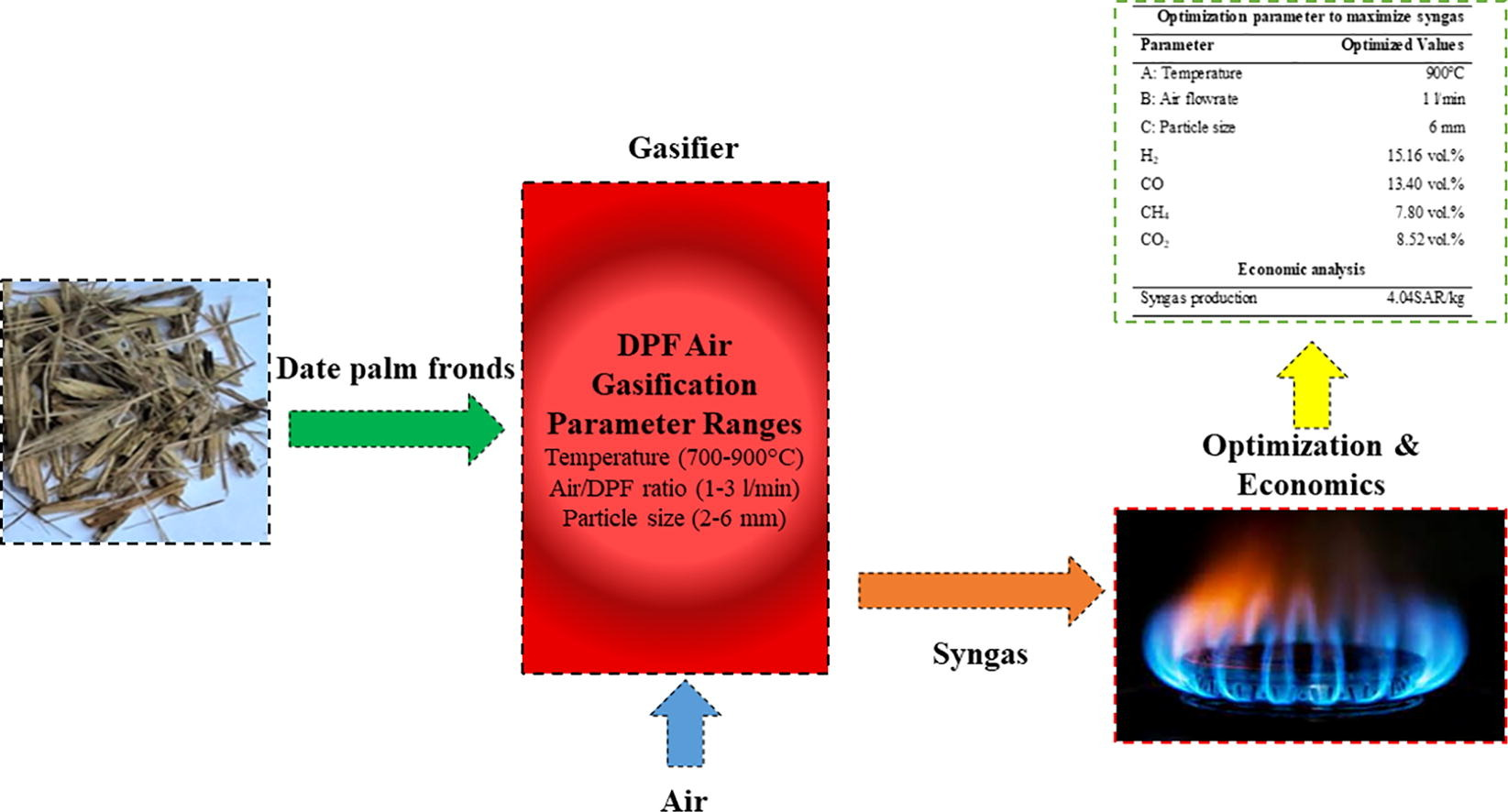

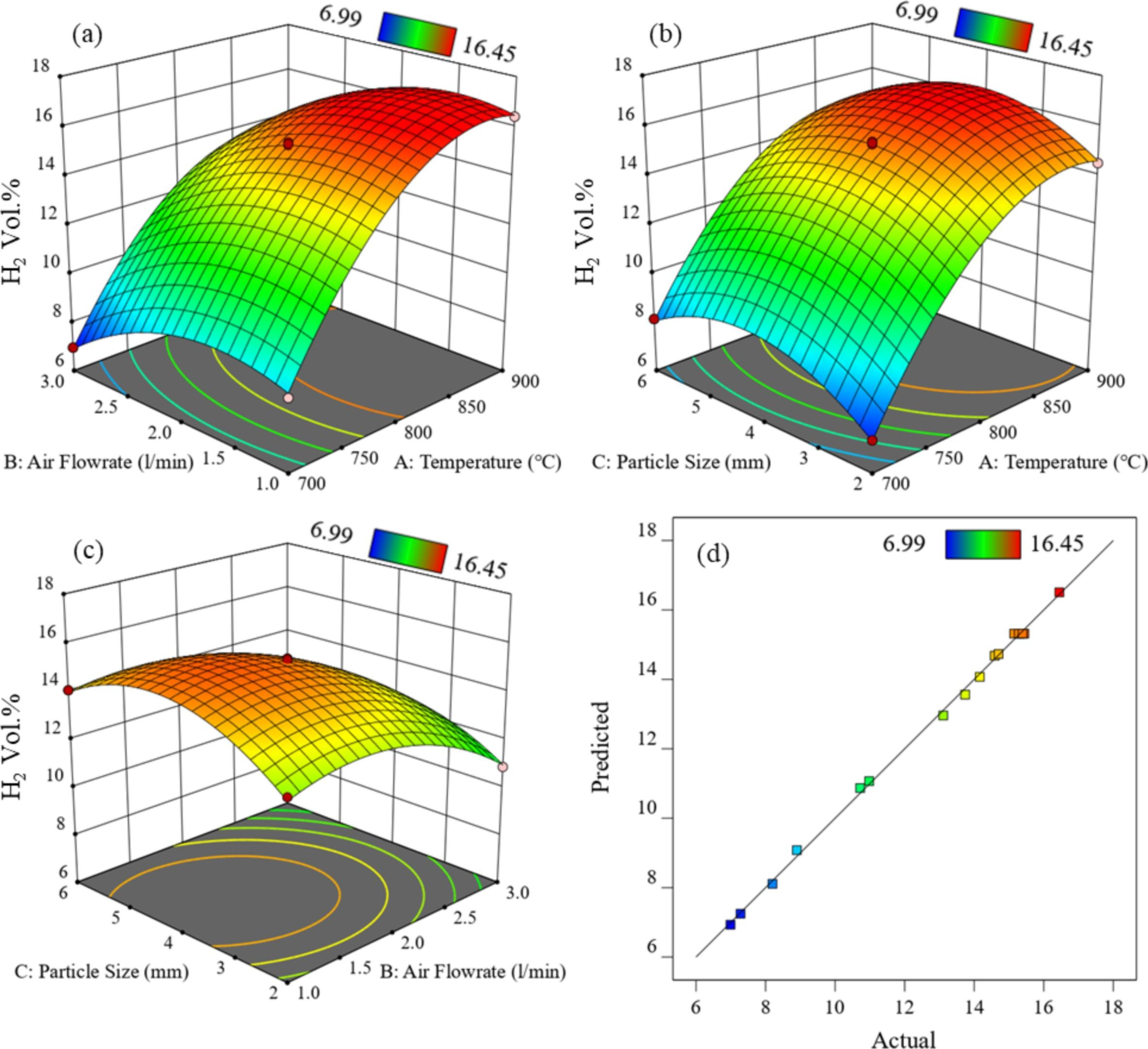

The transition of energy extraction from the fossil fuel to renewable energy is a primary drive-in world. Saudi Arabia is one of the big producer of date fruit which generates an abundant amount of date palm wastes. There is no proper utilization of these wastes in Saudi Arabia. Conversion of date palm waste into energy is a major potential alternative source of bioenergy via gasification. In current study, process optimization and economic evaluation of air gasification of date palm fronds (DPF) has been performed in downdraft gasifier for energy conversion. The impact of three process parameters temperature, air flowrate, and feedstock particle size on gas composition were investigated. The response surface methodology (RSM) was adopted for experimental design, optimization, and individual and interactive effects of parameters on H2 and CO compositions to find their optimum values. Temperature is the most influencing factor for H2 composition and it varies from 6 vol% to 18 vol% which is higher compared to air flowrate and feedstock particle size. A similar pattern of influencing factors was observed for CO composition it varies from 8 vol% to 20 vol%. The enrichment of H2 and CO is due to the activation of endothermic reactions at elevated temperature. On the other hand, factor influencing order for CO2 composition as feedstock particle size > air flowrate > temperature. The optimum conditions were found 900°C temperature, 1 l/min air flowrate, and 6 mm feedstock particle size to maximizing the H2 and CO compositions. Cost of syngas produced from air gasification of DPF was determined SAR 4.04/kg which can be minimized to scale-up the gasification system. DPF conversion into energy is environmentally friendly alternative source of renewable energy that will helps to reduce the dependency on fossil fuel.

Methodology

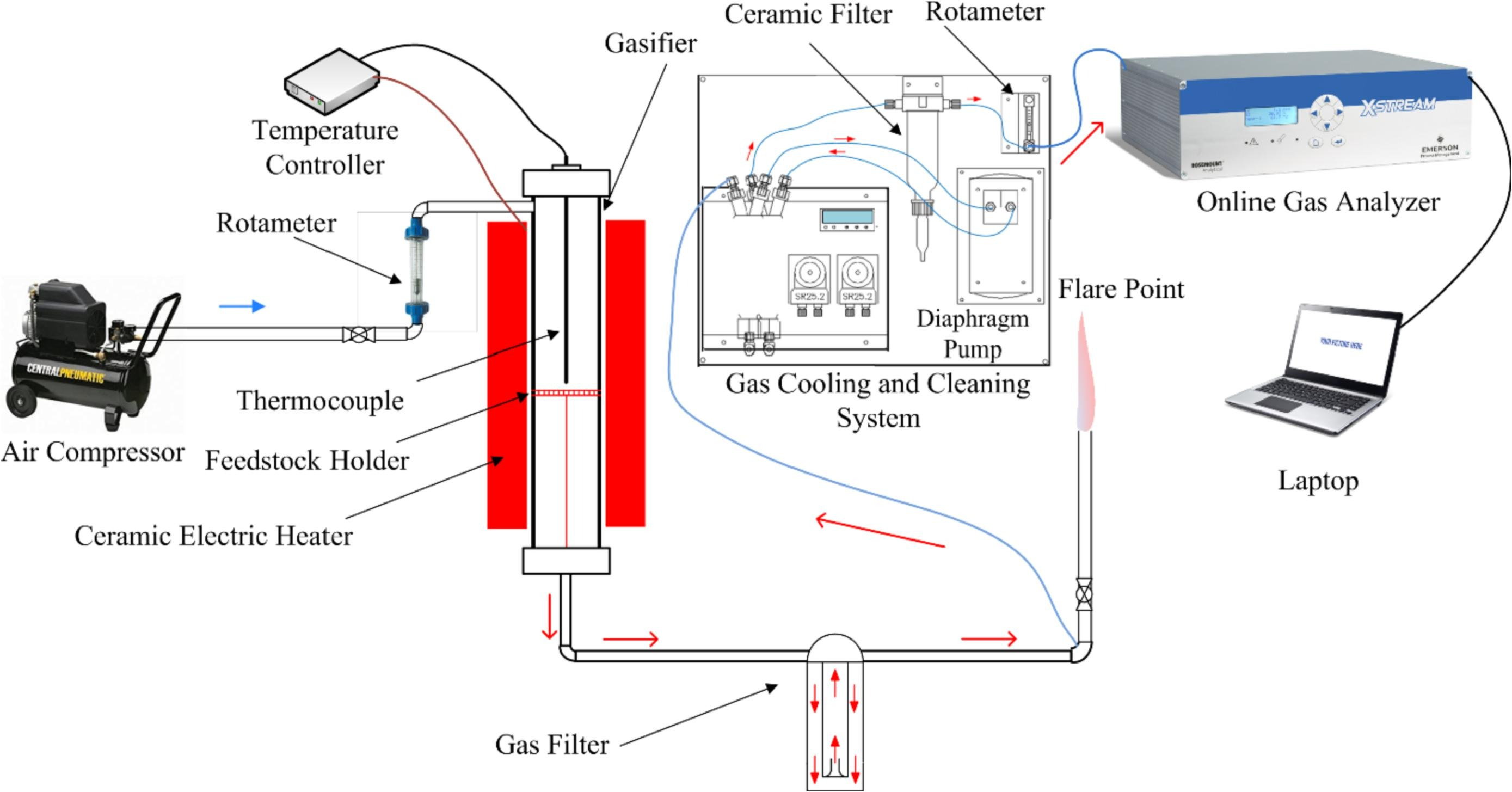

The experimental setup of downdraft gasification was used for this investigation is presented in Fig. 2. The downdraft gasifier was thermally insulated, and heating was carried out with the use of external electric ceramic heaters. The gasifier system and related tubing was purged with nitrogen gas and mechanically clean to remove the unburnt material, wastes, and ash before the start of each experiment. Gasifier was pre-heated to desire temperature by using electric ceramic heater and temperature control through a PID microcontroller. A K-type thermocouple was mounted inside the body of the gasifier to measure and display the process temperature. The gas analyzer system was switched no 15 min before measuring the samples through sample line. Once the desired temperature of the gasifier achieves, measured quantity (100 g) of prepared DPF was fed into the gasifier from its up led. A controlled and calculated quantity of air was injected into the fixed bed reactor; the air flowrate was maintained in the range of 1-3 l/min based on the tested runs. The measurement of the produced gas was made using an online gas analyzer (Emerson X-stream) that connects with the computer to display the results. The gas was sampled, analyzed, and data were recorded for every second.

Impact & Benefits

Resource Utilization: Date palm fronds are abundant agricultural waste in Saudi Arabia. By converting them into H2-rich syngas through air gasification, the study optimizes the utilization of this agricultural residue, turning it into a valuable resource.

Renewable Energy Production: Syngas produced from date palm fronds can serve as a renewable energy source, contributing to the diversification of Saudi Arabia's energy mix. This aligns with global efforts to reduce reliance on fossil fuels and mitigate climate change.

Process Efficiency: Optimization using response surface methodology allows for the identification of the optimal operating conditions for gasification. This leads to increased process efficiency, maximizing the yield of H2-rich syngas while minimizing energy consumption and waste generation.

Environmental Benefits: Gasification of date palm fronds offers environmental benefits by reducing the need for landfill disposal of agricultural waste, thus mitigating potential environmental pollution. Additionally, syngas produced from biomass is considered carbon-neutral since the carbon dioxide released during combustion is offset by the carbon dioxide absorbed during the growth of the biomass.

Market Potential

Energy Sector: As the world transitions towards renewable energy sources to combat climate change and reduce carbon emissions, there is a growing demand for sustainable alternatives to fossil fuels. The production of H2-rich syngas from biomass like date palm fronds presents an attractive option for renewable energy generation. This market potential is particularly significant in regions like Saudi Arabia, where there is ample availability of biomass resources.

Bioenergy Industry: The bioenergy industry encompasses various technologies aimed at converting biomass into energy, fuels, and chemicals. Gasification of date palm fronds offers a sustainable pathway for producing syngas, which can be further processed into hydrogen, methane, or other value-added products. This industry segment is poised for growth as countries seek to meet their renewable energy targets and reduce reliance on non-renewable resources.

Waste Management Sector: Date palm fronds are a significant agricultural waste stream in Saudi Arabia. By valorizing this waste through gasification, the technology addresses waste management challenges while simultaneously generating energy. Municipalities, waste management companies, and agricultural enterprises may be interested in deploying such solutions to optimize waste utilization and reduce environmental impacts.

Technology Providers: Companies specializing in biomass gasification technologies, process optimization, and renewable energy solutions can capitalize on the market potential of air gasification of date palm fronds. These firms can offer expertise, equipment, and consulting services to stakeholders interested in implementing gasification projects. Additionally, advancements in response surface methodology for optimization can enhance the efficiency and cost-effectiveness of gasification processes, thereby attracting investment and collaboration opportunities.