Investigations on spatial distribution of low temperature plasma parameters using NiCr wire probe diagnostic

Author: Shaharin Anwar Sulaiman - September 2016

Abstract

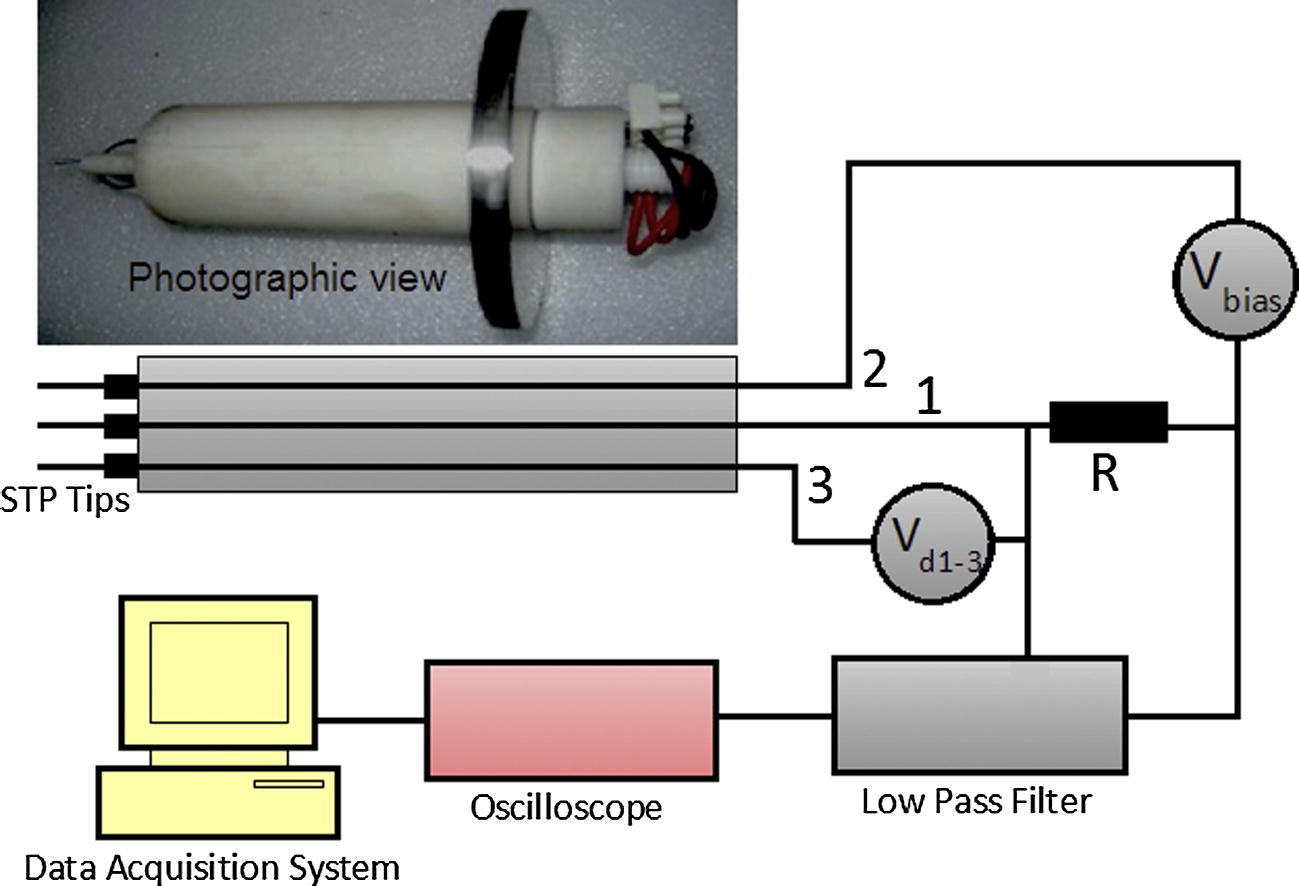

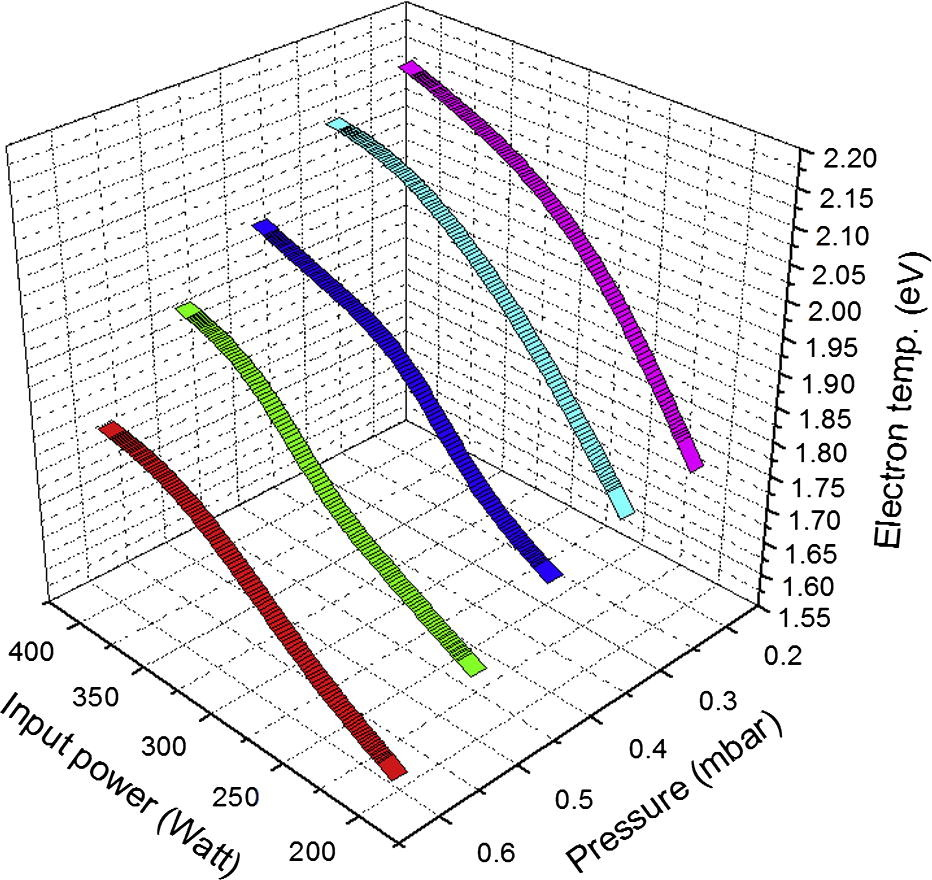

This study investigated the workability of a NiCr wire probe diagnostic under low temperature plasma operating conditions. The aim of the work was to design and fabricate a triple Langmuir probe with NiCr alloy for measurements in low temperature rf plasmas. The spatial distribution of electron temperature and number density were evaluated at different filling pressures in the range of 0.2-0.4mbar and rf powers in the range of 200-400W. The probe data revealed a linear increase in temperature and electron number density with rf power along the chamber centerline, whereas an inverse relationship was found between the given plasma parameters and filling gas pressure. The spatial distribution measurements showed a decreasing trend in plasma parameters at positions away from the chamber centerline. The probe I-V characteristics curve revealed a change in polarity of probe potential with an increase in current supply from the plasma discharge to the probe. Initially, the potential difference raised from highly negative values to zero volt, thereafter started increasing positively. It is found that the response of NiCr alloy as probe material was appreciably good under the proposed operating conditions.

Methodology

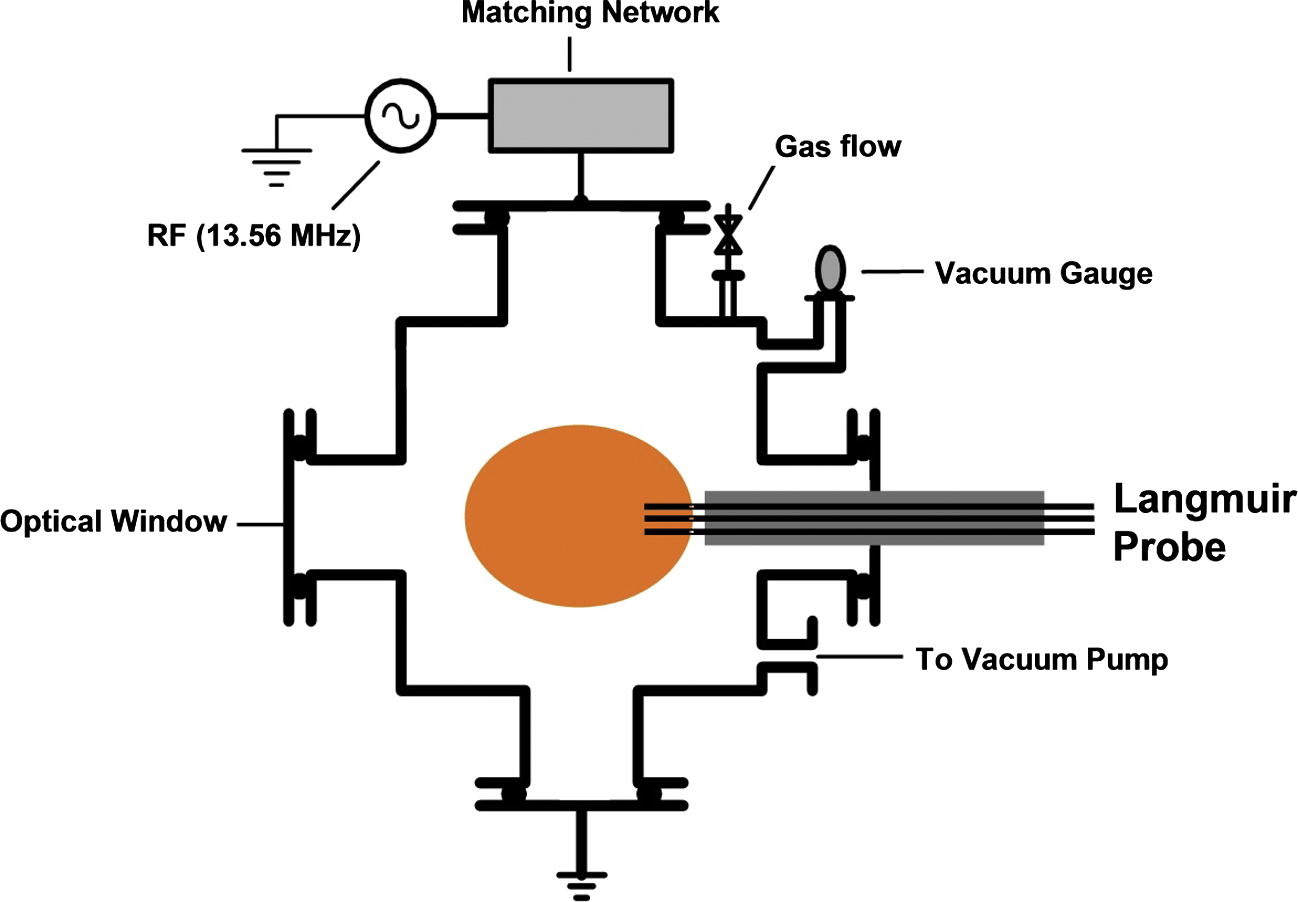

Fig. 2 shows schematic of experimental setup used for study of inductively coupled low temperature plasma. The nitrogen discharge was generated with a 13.56 MHz source coupled with an auto-matching network (Match Pro CPM-1000, Comdel, Inc.). This 50 Ω plasma source was connected to a spiral planar anode of 15 cm diameter. The copper cathode was placed on stainless steel chamber. This barrel shaped chamber was 24 cm in height and 31 cm in diameter. The metallic chamber was isolated from the copper electrode by introducing a quartz slab between them. This slab was also helping to uphold coveted vacuum and pressure of the chamber. To keep reflected power less than 2% and to boost the exchange of power from power source to chamber, a programmable impedance matching system was used crosswise over power source and copper anode. For flow mode operation, a rotary vane pump was working with chamber. The gas flow from primary source to plasma chamber was regulated through gas flowmeter. At this end, a Pirani gauge was used to monitor the gas pressure.

Impact & Benefits

Understanding Plasma CHaracteristics: This diagnostic method helps in understanding the behavior and characteristics of low-temperature plasmas. By measuring parameters such as electron density, electron temperature, and plasma potential at different spatial locations, researchers can gain insights into how the plasma behaves in various regions of the reactor or device under study.

Optimization of Plasma Processes: By mapping out the spatial distribution of plasma parameters, researchers can optimize plasma processes for specific applications. For example, in plasma-based material processing techniques like plasma etching or deposition, knowing the spatial distribution of parameters can help in achieving uniform processing across the substrate surface, leading to improved device performance and yield.

Diagnostic Tool Development: Investigating the spatial distribution of plasma parameters using NiCr wire probes contributes to the development of diagnostic tools for characterizing plasmas. This can lead to the refinement and development of new diagnostic techniques that can provide more detailed information about plasma behavior and properties.

Validation of Plasma Models: The data obtained from these investigations can be used to validate and refine plasma models. Computational models of plasmas rely on experimental data for validation, and spatially resolved measurements using NiCr wire probes can provide valuable validation data for improving the accuracy of plasma simulations.

Market Potential

Research and Development (R&D): There is a significant market potential in the R&D sector, where universities, research institutions, and private companies invest in understanding and optimizing plasma processes for various applications. As plasma technology finds applications in industries such as semiconductor manufacturing, aerospace, healthcare, and energy, there is a growing demand for advanced diagnostic techniques to improve process efficiency, quality, and reliability.

Semiconductor Industry: The semiconductor industry extensively utilizes plasma processes for etching, deposition, and surface modification. Investigating the spatial distribution of plasma parameters can lead to better control and optimization of these processes, thereby improving device performance and yield. As the demand for smaller, faster, and more efficient semiconductor devices continues to grow, there is a corresponding demand for advanced plasma diagnostics.

Materials Processing: Beyond semiconductors, plasma technology is increasingly being used in materials processing applications such as thin-film coatings, surface modification, and nanomaterial synthesis. Understanding the spatial distribution of plasma parameters can enhance the uniformity and reproducibility of these processes, making them more attractive for industries ranging from automotive and aerospace to healthcare and consumer electronics.

Environmental and Energy Applications: Plasma technology also holds promise for environmental remediation, water treatment, and energy generation. Investigating plasma parameters can help in optimizing plasma-based processes for pollution control, wastewater treatment, and renewable energy generation. As environmental regulations become stricter and the demand for clean energy solutions increases, there is a growing market potential in these sectors.