Effect of Crude Oil and Nitrogen Gas Flow Rates on the Time Taken for Flow Initiation of Waxy Crude Oil

Author: Shaharin Anwar Sulaiman - May 2023

Abstract

Transportation of waxy crude oil in a production pipeline often encountered flow assurance issues, such as wax deposition. In a case where pipeline shutdown is needed, wax deposit is likely to form within the pipelines, which leads to operational complexity during the restart phase. Commonly, crude oil restarts to flow after a significantly high restart pressure is pumped longer than is necessary. This is due to the physical hindrance caused by the solid wax, which requires additional pressure to disintegrate it before achieving a steady crude oil flow. This study aims to investigate the effect of crude oil and nitrogen gas flow rates on the time taken for crude oil flow initiation using a flow loop rig, which is connected to a nitrogen gas injection system. The nitrogen gas was injected into the test section pipeline at predetermined flow rates within specified periods. After 45 min of static cooling, the crude oil gear pump is switched on to build sufficient pressure to initiate the waxy crude oil flow in the pipeline. Additionally, a statistical analysis by the response surface methodology was also performed by Minitab 19 software. Results show that the maximum reduction in flow initiation is 73.7% at 5 L/min of crude oil and 1 L/min of nitrogen gas. This study reveals that the presence of nitrogen gas improved the pipeline restart phase by minimizing both restart pressure and time taken for flow initiation.

Methodology

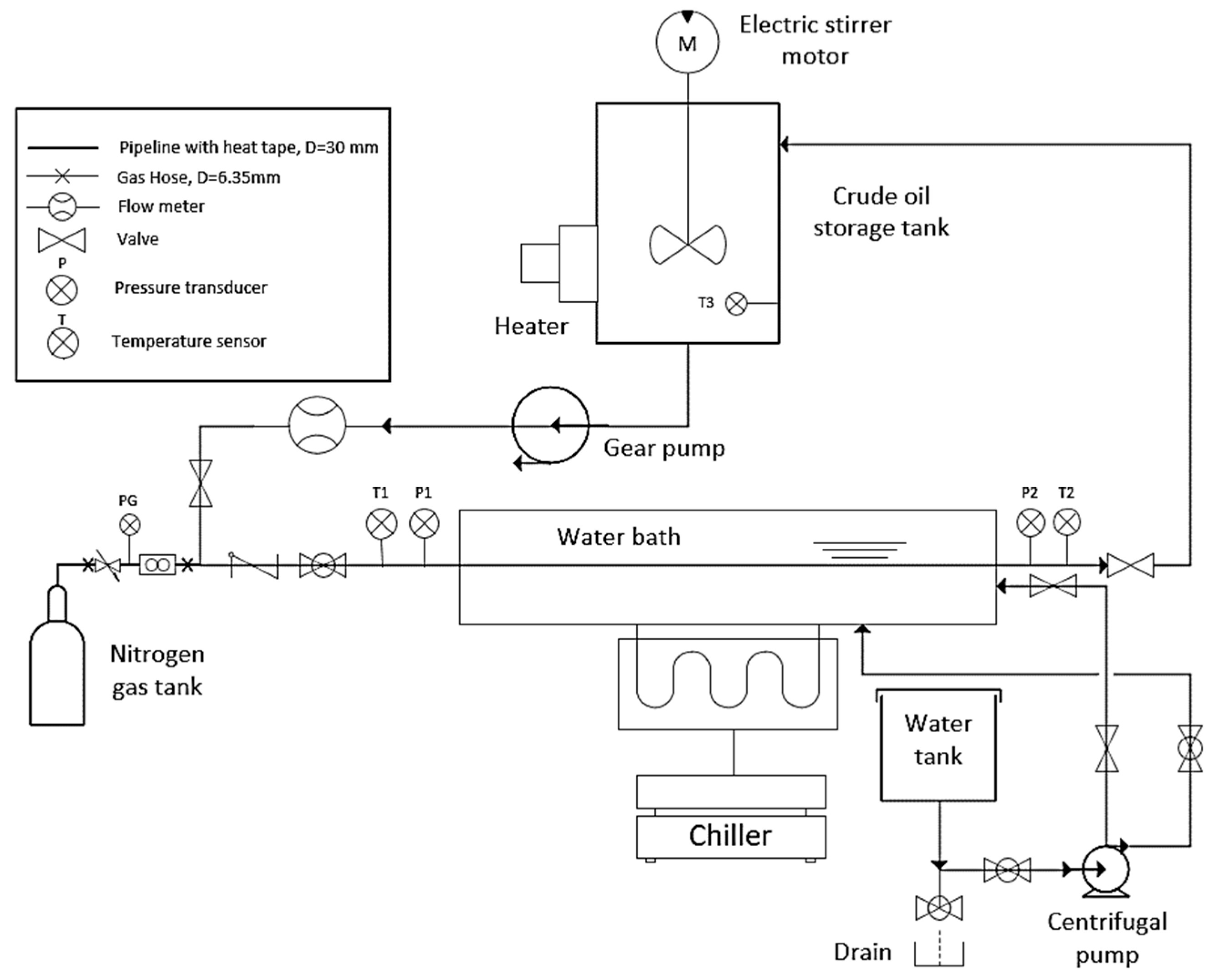

General setting and operating conditions of the flow loop system are similar with published procedures [32,33]. Before any fresh cycle of investigation starts, the flow loop system needs to undergo pre-operation. Firstly, a heater that connects to a waxy crude oil storage tank is switched on. A set temperature is higher than the WAT of the crude oil to liquefy any waxes. Heater extension that coils around the pipelines (except the test section pipe) is also switched on to increase the temperature of crude oil inside the pipeline. After 5 min, an electric stirrer in the waxy crude oil storage tank is turned on to ensure homogeneous heating within the tank. This is to remove any past thermal behaviour history of crude oil. After ~30 min, a crude oil gear pump is switched on to have a steady flow of crude oil of 15 L/min. The flow loop system is now ready for the study. A chiller system is switched on to reduce the water bath temperature to 26 °C (mimicking seawater temperature). After several minutes of steady flow was achieved, the crude oil volume flow rate was decreased to a predetermined value, and nitrogen gas was injected into the inlet of the test section pipeline before the crude oil gear pump was switched off entirely. This was to replicate the pipeline shutdown condition at field.

Impact & Benefits

Optimization of Production Processes: Understanding how different flow rates of crude oil and nitrogen gas affect the initiation of flow can help in optimizing production processes in oil fields. By determining the optimal flow rates, operators can enhance the efficiency of oil extraction and transportation.

Reduced Downtime: Identifying the conditions that facilitate the initiation of flow can lead to reduced downtime in oil production operations. This is particularly crucial in environments where waxy crude oil is prevalent, as wax deposition can often cause flow blockages and operational disruptions.

Prevention of Flow Assurance Issues: Waxy crude oils are prone to flow assurance issues such as wax deposition and pipeline blockages. By studying flow initiation under different flow rate conditions, researchers can develop strategies to mitigate these issues, ultimately ensuring uninterrupted oil flow from reservoirs to refineries.

Cost Reduction: Optimizing flow rates can lead to cost reductions in oil production and transportation. By minimizing the time taken for flow initiation, operators can enhance operational efficiency and reduce energy consumption, ultimately lowering production costs.

Market Potential

Oil Production and Exploration Companies: Companies involved in oil production and exploration are constantly seeking ways to optimize their operations to increase efficiency and reduce costs. Research findings and technologies that help in understanding and controlling flow initiation of waxy crude oil can be highly valuable to these companies. They may invest in implementing new equipment, protocols, or strategies derived from such research to enhance their production processes.

Flow Assurance Solutions Providers: Flow assurance is a critical aspect of oil production and transportation, especially for waxy crude oils. Companies specializing in flow assurance solutions, such as chemical treatments, coatings, and monitoring systems, can leverage research findings to develop innovative products tailored to address flow initiation challenges associated with waxy crude oils. This can open up new market opportunities for flow assurance solution providers.

Oilfield Services COmpanies: Oilfield services companies offering well stimulation, production enhancement, and pipeline maintenance services can benefit from insights into flow initiation dynamics. They can use this knowledge to improve their service offerings, develop customized solutions for clients dealing with waxy crude oils, and differentiate themselves in the market.

Research Institutions and Academia: Research institutions and academic organizations engaged in studying fluid dynamics, petroleum engineering, and related fields can explore the market potential for collaborative research projects, consulting services, and technology transfer initiatives focused on flow initiation of waxy crude oil. They can partner with industry players to conduct research, provide expertise, and develop innovative solutions.