Effect of urea and borate plasticizers on rheological response of corn starch

Author: Shaharin Anwar Sulaiman - September 2017

Abstract

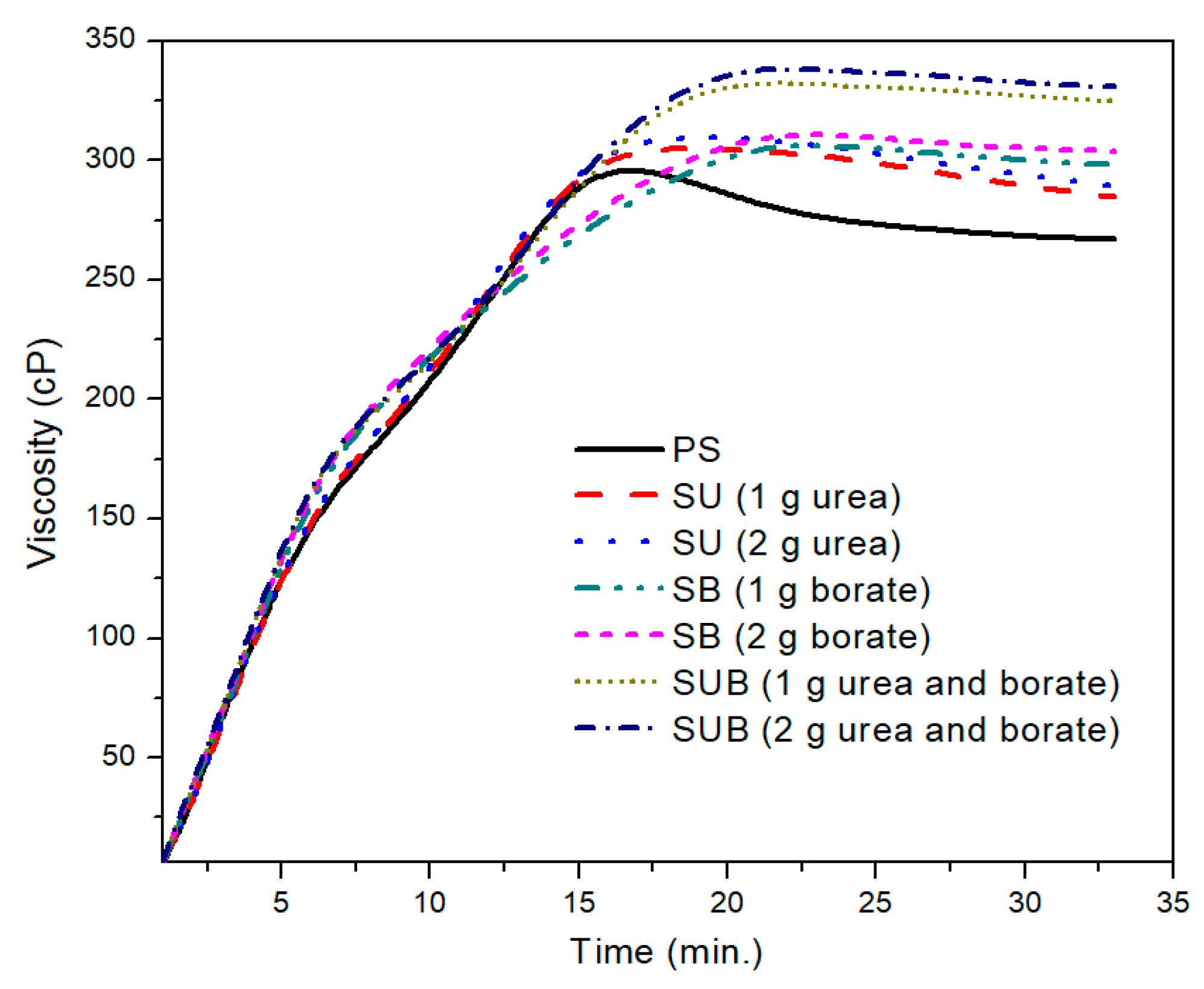

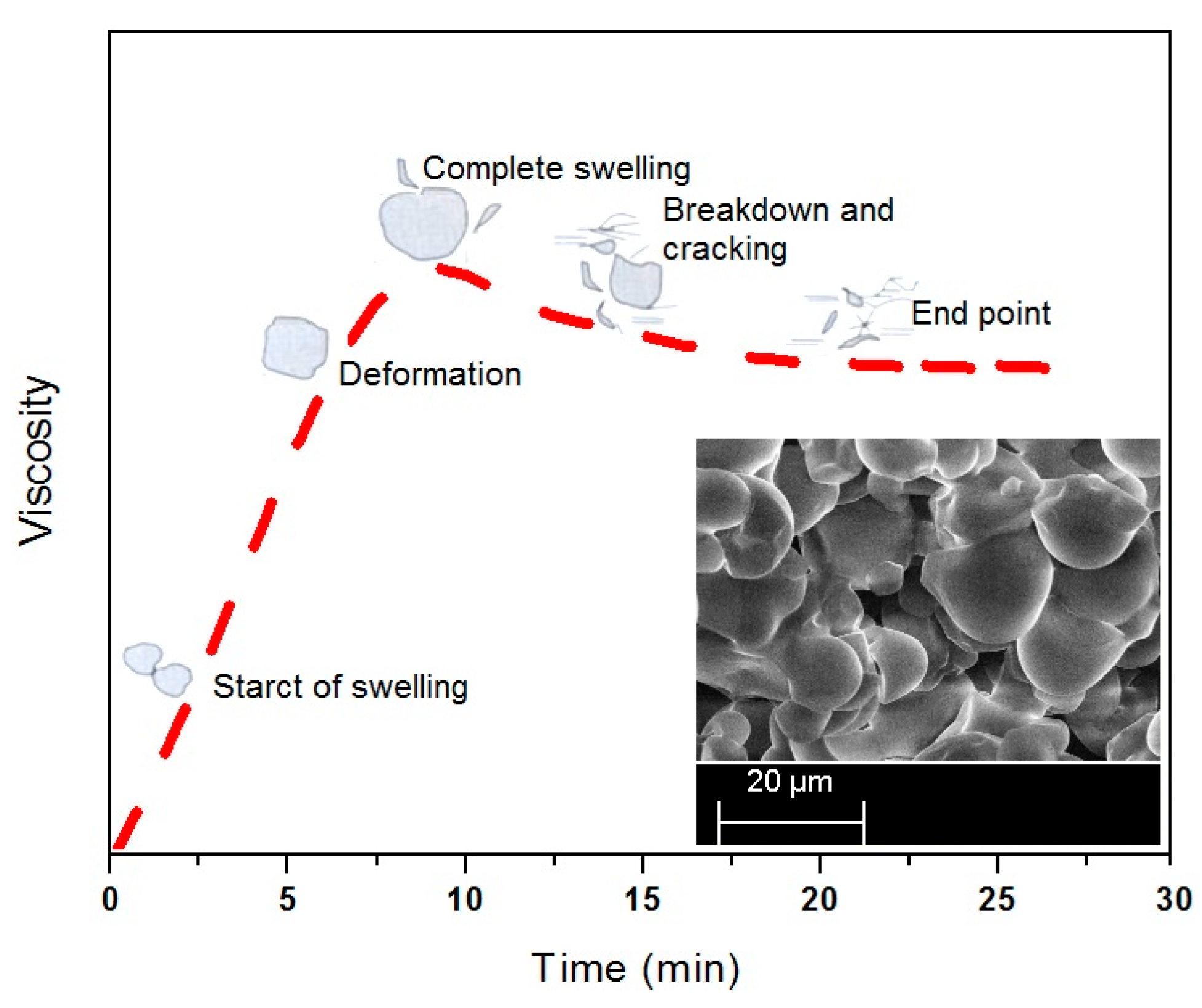

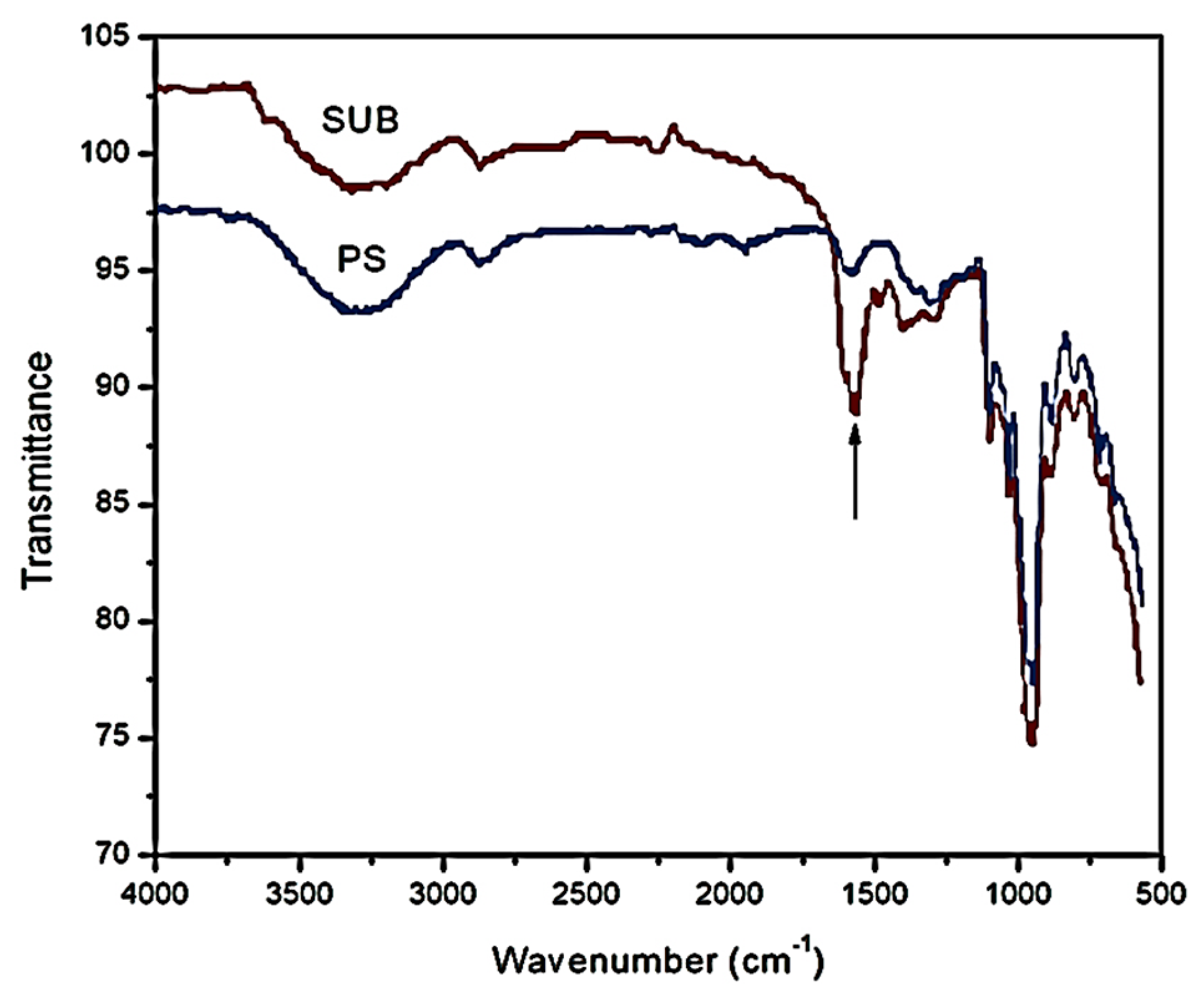

Although starch based materials have an array of fascinating industrial applications, the native starches do not show good mechanical strength, thermal stability, and rheological properties for their use in the mainstream processing industry. For example, the use of starches for producing controlled release fertilizers is a new research endeavor with detailed knowledge still to come. The thermal processing of native starches with water as a plasticizer results in poor physical and pasting properties of the final product. Therefore in this study, corn starch was thermally processed with urea and borate in a water medium. The pure starch (PS), starch-urea (SU), starch-borate (SB), and starch-urea-borate (SUB) samples were prepared and characterized for their rheological traits. The PS sample exhibited a peak viscosity of 299 cP after 17 min of thermal processing. Further heating of the suspension caused a decrease in viscosity of 38 points due to thermal cracking of the starch granules. A similar trend was depicted in the viscosity measurements of SU, SB, and SUB adhesives. However, the viscosity of these samples remained slightly higher than that for PS. Also, the reduction in viscosity after the peak value was not as notable as for PS. The modified starch behaved like a gel and its storage modulus was significantly higher than the loss modulus. The lower magnitudes of storage and loss moduli revealed that the modified starch was in the form of a weak gel and not a solid. The PS is more fluid in nature with dominating loss modulus at lower angular frequencies.

Methodology

The food grade corn starch was purchased from the local market (Faisalabad, Pakistan) and dried under sunlight to removal the moisture content. The plasticizer was 98% de-ionized water whereas the other constituents were urea and borate (Na2B4O7⋅10H2O) of Analytical Reagent (AR) grade (Faisalabad, Pakistan). The starch with degree of substitution of 0.81 was reacted with urea and borate in water medium. The degree of substitution of a polymer is defined as the average number of substituent groups attached with a base unit or a monomeric unit. Six samples of the modified starch were prepared and characterized for their physical and rheological traits. Details of the formulation of theses starch based adhesives are given in Table 1.

Impact & Benefits

Improved Rheological Properties: Urea and borate plasticizers can modify the rheological properties of corn starch-based materials, including viscosity, shear thinning behavior, and elasticity. This modification can enhance processability, making it easier to handle during manufacturing processes such as extrusion, molding, or coating application.

Enhanced Mechanical Properties: The addition of plasticizers can improve the mechanical properties of corn starch-based materials, including tensile strength, flexibility, and impact resistance. This can result in products with better durability and performance.

Reduced Costs: By effectively utilizing urea and borate as plasticizers, manufacturers may reduce production costs compared to using more expensive or less efficient additives. This cost reduction can make corn starch-based products more competitive in the market.

Environmental Benefits: Urea and borate plasticizers are often considered more environmentally friendly alternatives compared to some traditional plasticizers derived from petrochemicals. Additionally, corn starch itself is a renewable and biodegradable resource, so using it as a base material along with eco-friendly plasticizers aligns with sustainability goals.

Market Potential

Growing Demand for Sustainable Materials: There is a rising global demand for sustainable materials driven by increasing environmental awareness and regulations aimed at reducing the use of traditional plastics. Corn starch-based materials, especially when enhanced with eco-friendly plasticizers like urea and borate, offer a biodegradable and renewable alternative that aligns with sustainability goals.

Shift Towards Bioplastics: The bioplastics market has been experiencing significant growth due to concerns over plastic pollution and the depletion of fossil fuel resources. Corn starch-based materials, with their potential to be biodegradable and derived from renewable sources, are well-positioned to capture a share of this expanding market, especially when their rheological properties are optimized with the use of plasticizers.

Advantages in Various Industries: The impact of urea and borate plasticizers on the rheological response of corn starch extends to multiple industries, including packaging, food and beverage, textiles, cosmetics, and pharmaceuticals. Each of these industries has unique requirements for materials with specific rheological properties, and corn starch-based materials with tailored rheology can find applications in a wide range of products within these sectors.

Regulatory Drivers: Regulatory initiatives aimed at reducing the environmental impact of plastic materials, such as bans on single-use plastics and mandates for biodegradable packaging, are creating opportunities for innovative materials like corn starch-based plastics. The use of eco-friendly plasticizers further enhances the compliance of these materials with evolving regulations.