Gasification performance of sawdust, pelletized sawdust and sub-bituminous coal in a downdraft gasifier

Author: Shaharin Anwar Sulaiman - August 2020

Abstract

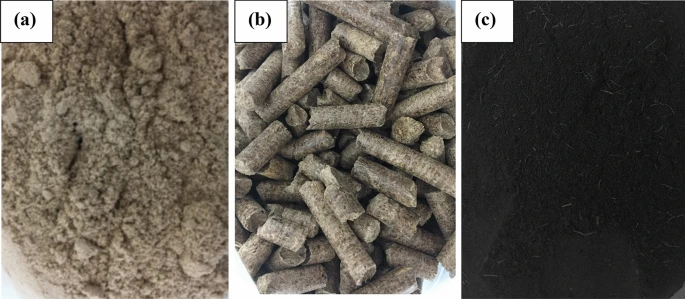

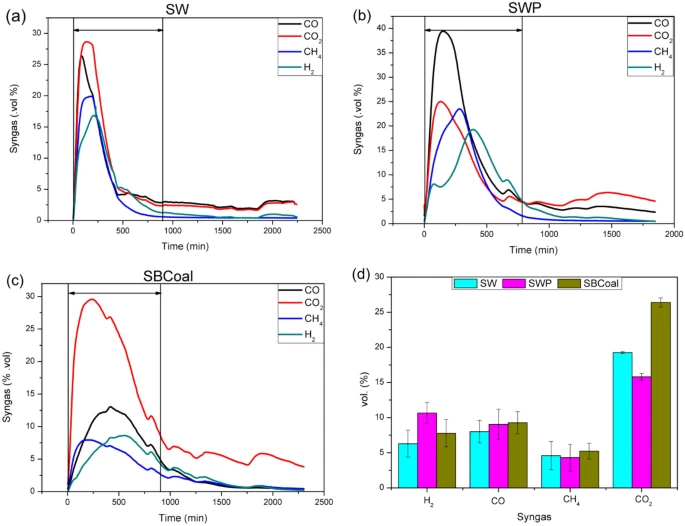

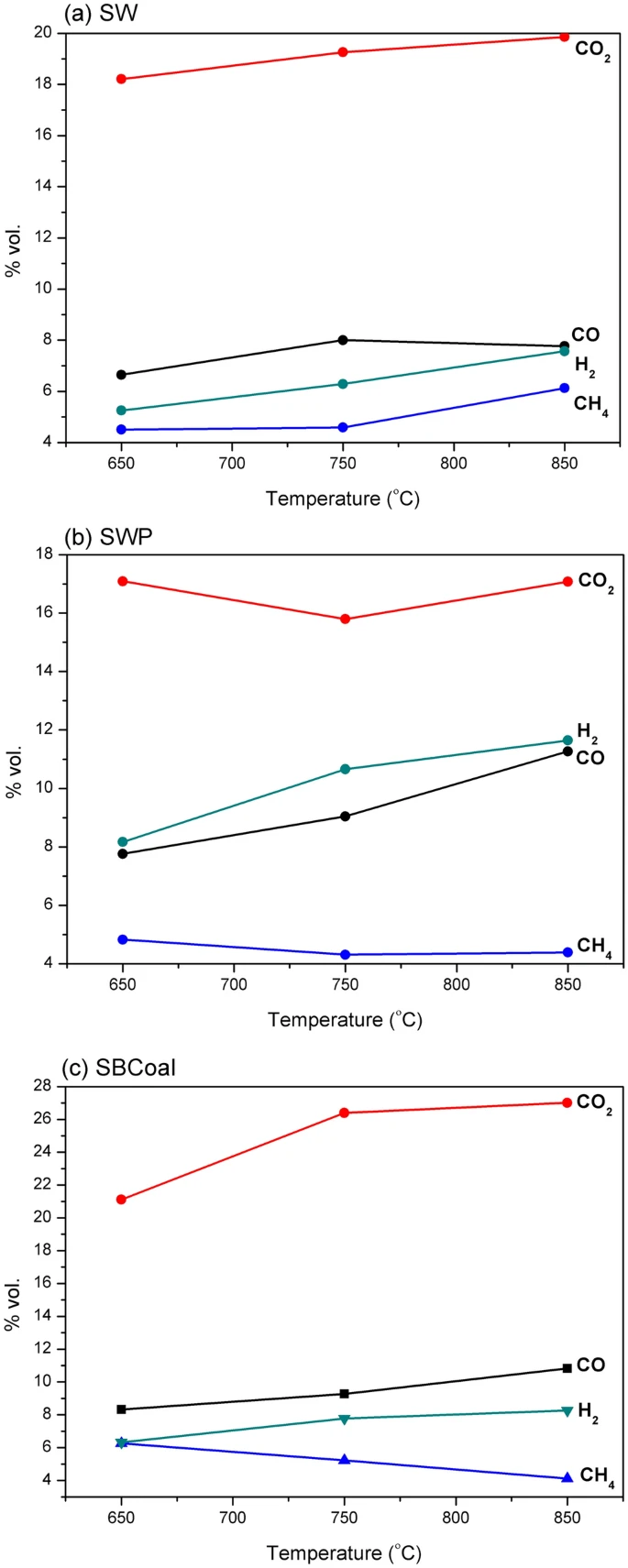

The paper is an experimental study of the gasification process of sawdust (SW), sawdust pellet (SWP) and sub-bituminous coal (SBCoal) by using downdraft gasifier. The gasification was undertaken in a lab-scale fixed-bed gasifier operating under air as an oxidizing agent. The comparison on the raw biomass, treated biomass and coal was assessed in term of the product gas and gasification performance at a fixed condition of gasification temperature of 750 °C and equivalence ratio of 0.25. The gasification performance was tabulated in the form of calorific value of the syngas (HHVsyngas), gasification efficiency (XCGE) and carbon conversion efficiency (XC). It was denoted that SWP produces the highest H2 and the lowest CO2. Furthermore, SBCoal possesses the highest gasification performance among the three feedstocks. Besides, the influence of the temperature between SW, SWP and SBCoal was evaluated at the equivalence ratio of 0.25. The findings demonstrate that rising the temperature, H2 and CO for SW, SWP and SBCoal are increase. The volume of the CO2 is constant as the temperature increases. In contrast, the CH4 decreases with increase in the gasification temperature. As the gasification temperature increases, HHVsyngas and XCGE of SW and SWP are increasing; meanwhile, SBCoal shows the opposite results. Simultaneously with rising gasification temperature, the XC's of the SW, SWP and SBCoal are increasing.

Methodology

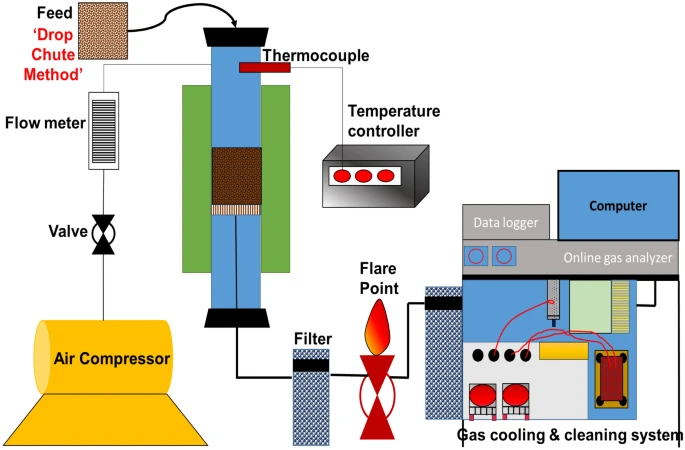

Figure 2 shows the schematic diagram of the gasification system used throughout the whole gasification process for each feedstock that located at the biomass laboratory, under Department of Mechanical Engineering, Universiti Teknologi Petronas (UTP), Perak. The gasification system was comprised into three main units: the gasifier reactor, the gas cleaning and cooling machine and gas analyzer. The total height of the gasifier reactor is 500 mm with the internal diameter of 80 mm. The air was introduced into the gasifier reactor as an oxidizing agent by the compressed air from the top side of the gasifier reactor. Furthermore, the rotameter was attached beside the gasifier reactor functioning to measure and control the airflow rate. An electric furnace was enclosed around the gasifier reactor to generate heat to the reactor. The remaining solids of the feedstock that falls to the lower part of the grate was collected at the opening bottom together with the gas discharge hole that located in the low end part of the gasifier reactor.

Impact & Benefits

Energy Generation: Gasification converts solid biomass and coal into a combustible gas mixture known as syngas, which can be used for generating heat and electricity. This process helps utilize these feedstocks efficiently for energy production.

Reduced Waste: Sawdust, pelletized sawdust, and sub-bituminous coal are often waste or byproducts of other processes. Gasification provides a method to convert these materials into useful energy, reducing waste and environmental impact.

Cleaner Energy: Syngas produced from gasification tends to have lower emissions compared to direct combustion of the feedstocks. Gasification allows for better control of the combustion process, leading to reduced emissions of pollutants like sulfur dioxide, nitrogen oxides, and particulate matter.

Flexibility: Gasifiers can often handle a variety of feedstocks, including biomass and coal. This flexibility allows for adaptation to changing feedstock availability and cost, providing stability in energy production.

Market Potential

Energy Demand: The demand for clean and renewable energy sources continues to grow globally, driven by concerns over climate change, air pollution, and energy security. Gasification offers a way to utilize biomass and coal resources more efficiently, tapping into this growing demand.

Feedstock Availability: The availability of sawdust, pelletized sawdust, and sub-bituminous coal varies by region. Areas with abundant forestry or agricultural residues, such as sawmills or wood processing facilities, may have a readily available supply of feedstock for gasification. Similarly, regions with coal mining activities can utilize sub-bituminous coal for gasification.

Regulatory Environment: Regulations and policies supporting renewable energy, carbon reduction, and clean air can drive market opportunities for gasification technologies. Incentives such as feed-in tariffs, renewable energy credits, or carbon pricing mechanisms can make gasification projects more economically viable.

Technology Maturity and Cost: The maturity of gasification technology and associated costs play a significant role in market adoption. Advances in gasifier design, process optimization, and scale economies can lower capital and operational costs, making gasification more competitive with conventional energy sources.