Effect of producer gas staged combustion on the performance and emissions of a single shaft micro-gas turbine running in a dual-fuel mode

Author: Shaharin Anwar Sulaiman - February 2017

Abstract

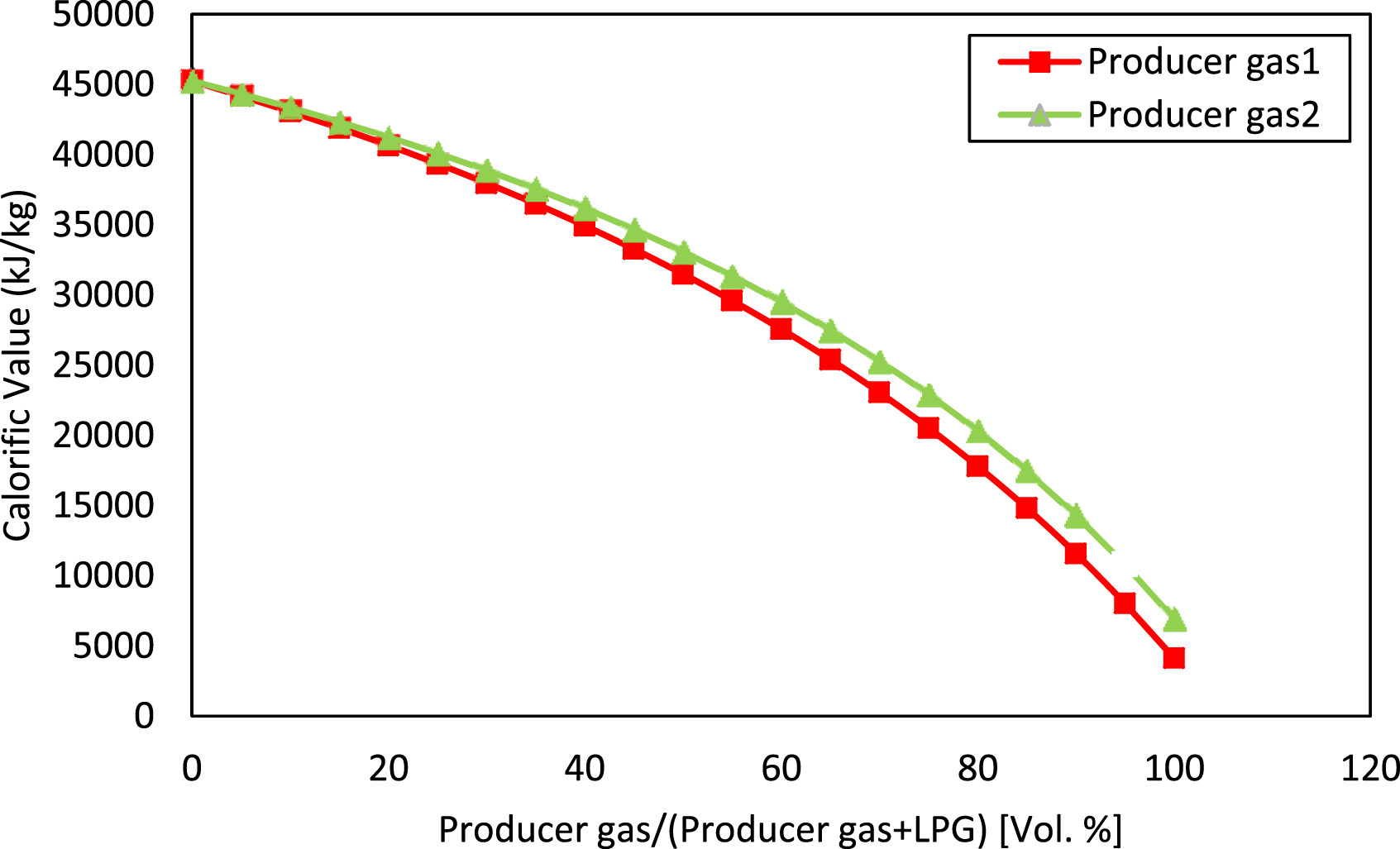

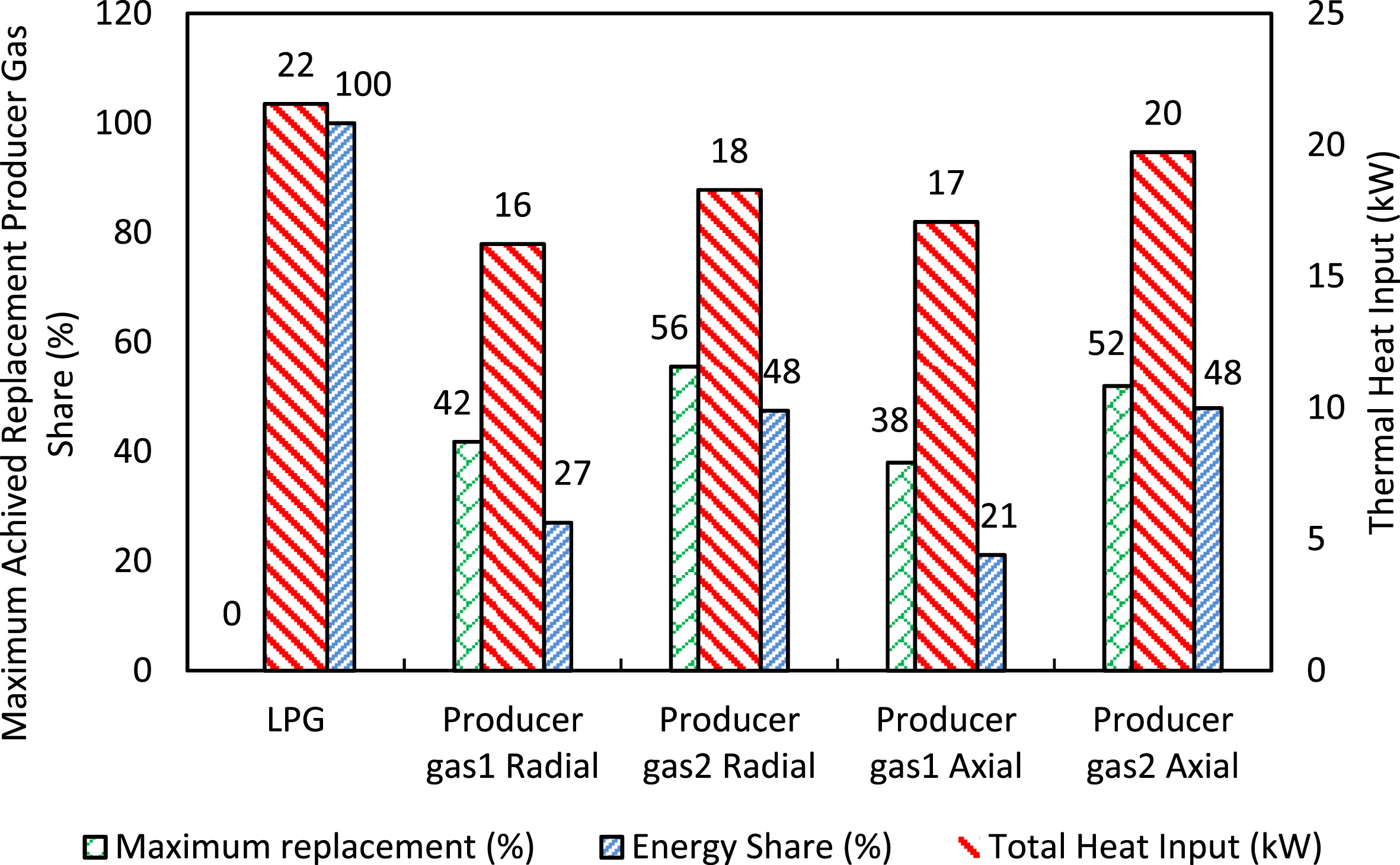

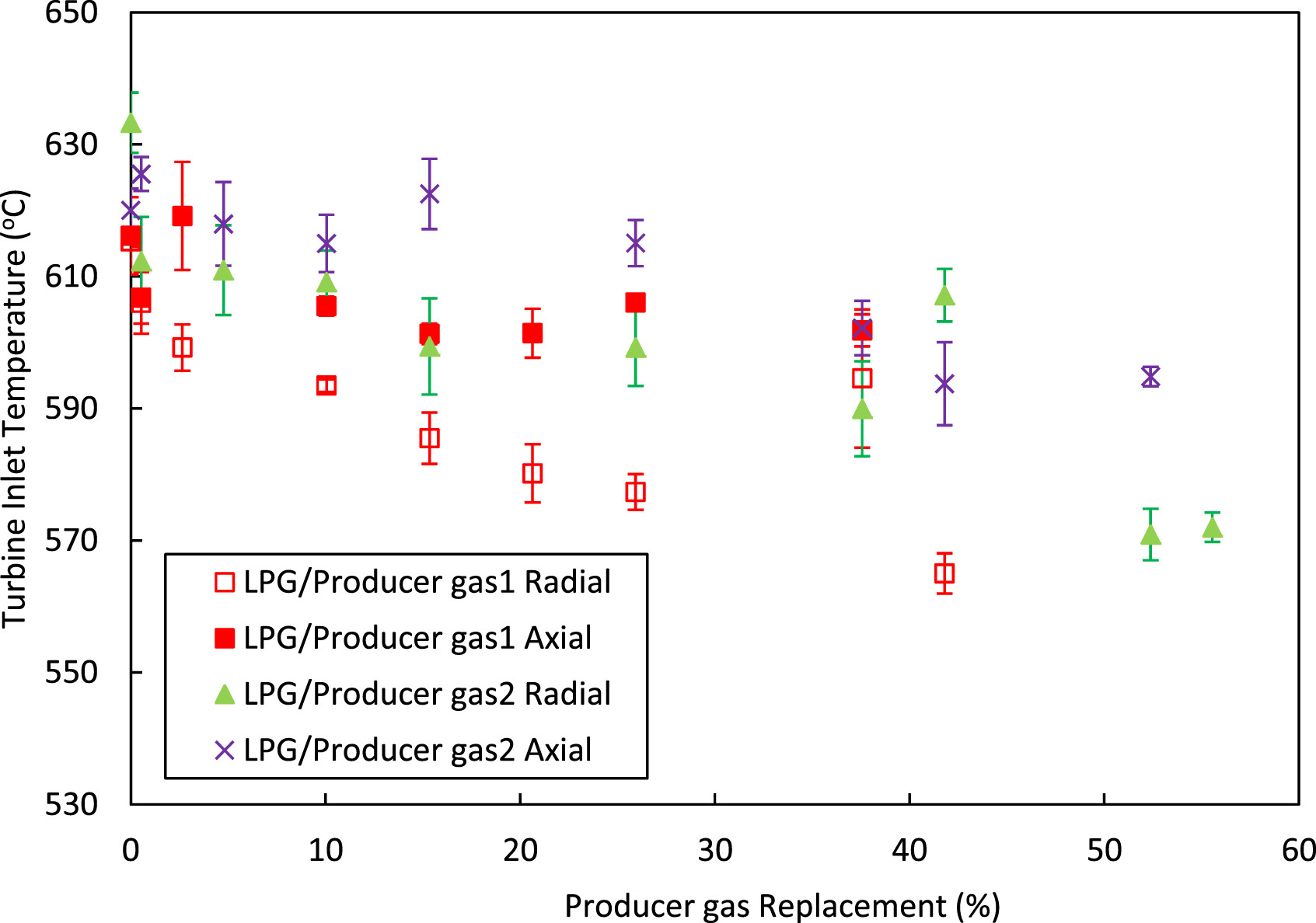

Producer gas from biomass gasification has a potential to cover a considerable part of power production in the future, the availability and variety of biomass put it as the fourth energy resource. The use of producer gas fuels in gas turbine engines can help mitigating problems related to fossil fuels depletion, emissions and biomass waste disposal. In this work, the effect of the staged combustion of a simulated low calorific value producer gas fuels on the performance and emissions of a single shaft micro gas turbine was investigated experimentally. In order to perform the experiments, the micro gas turbine system was characterized first with the liquefied petroleum gas (LPG) and then tested with two producer gas fuels, producer gas1 (10.53% H2, 24.94% CO, 2.03% CH4, 12.80% CO2, and 49.70% N2) and producer gas2 (21.62% H2, 32.48% CO, 3.72% CH4, 19.69% CO2, and 22.49% N2) in a dual fuel mode. Two injection methods were proposed and tested for producer gases including radially and axially injection. The tests were examined in terms of LPG fuel replacement, turbine entrance temperature, combustor efficiency, turbine efficiency, and emission characteristics at different LPG fuel replacement ratios. The study showed stable operation with a maximum LPG replacement of 42% and 56% for the radially injected producer gas1 and producer gas2, respectively. While for the axially injected producer gas fuels, the maximum achieved LPG replacement ratio was 38% and 52% for producer gas1 and producer gas2, respectively. A relatively higher efficiencies for the combustor and turbine with a remarkable reduction in NOx emissions were achieved when LPG fuel was replaced with producer gas fuels. On the other hand CO emissions were increased for both injection methods.

Methodology

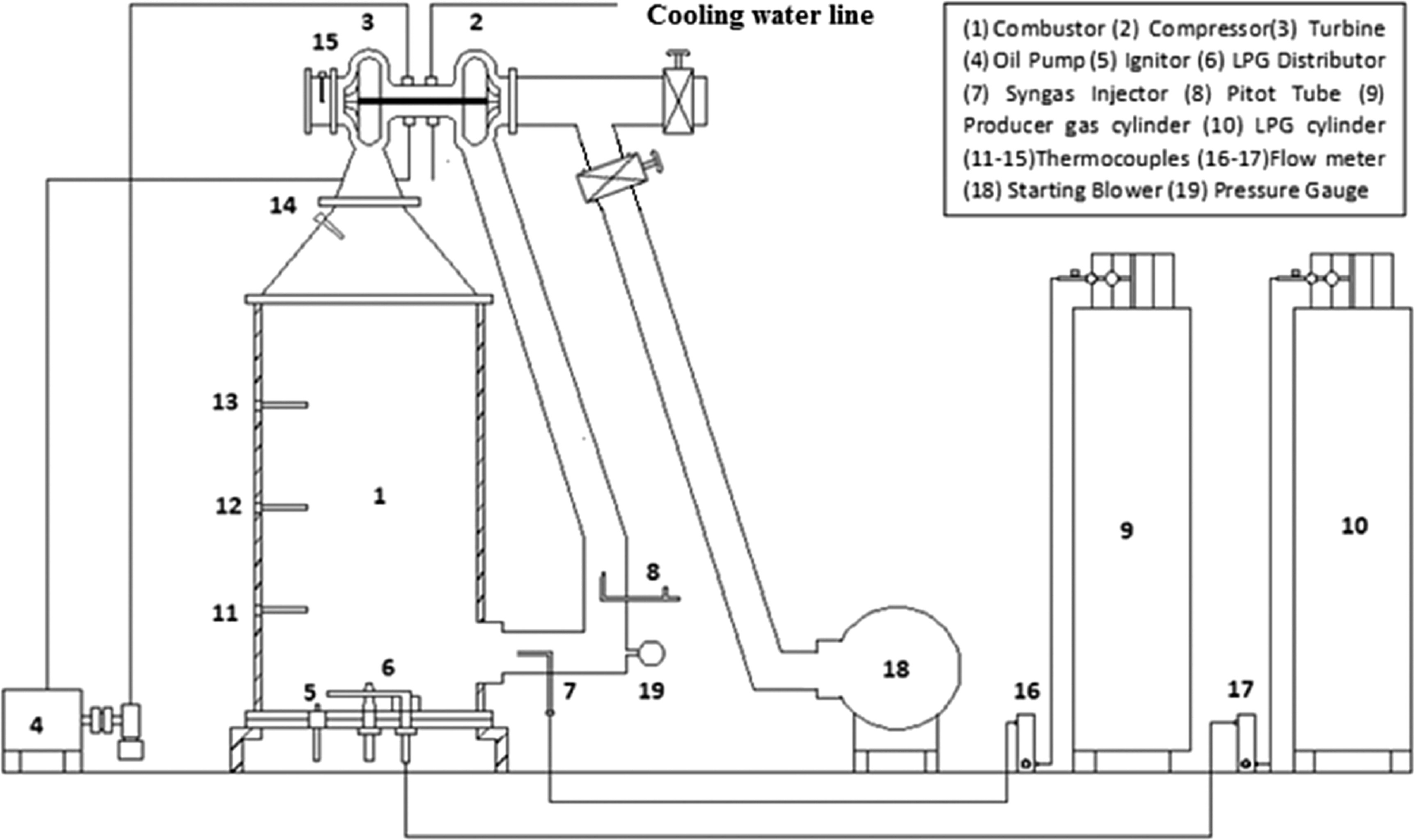

The single shaft micro-gas turbine is consisted of combustor, compressor and turbine; a schematic diagram of the experimental rig is shown in Fig. 1. In order to reduce the cost and due to the complication in the gas turbine parts fabrication, the basic idea for the development of the experimental rig was based on the utilization of vehicle turbocharger to be used as a compressor and turbine. In this work, the tests were conducted in order to study the effect of producer gas staged combustion on the performance and emissions of the micro gas turbine system. The combustion was started on LPG then a gradual replacement of LPG with producer gas was applied. The flow rate of the used fuels was measured using calibrated CONCOA flow meters. A calibrated Pitot tube and pressure gauge were attached in the compressed air line and used to measure the flow rate and pressure of the air leaving the compressor. Six K type thermocouples were attached to monitor the temperature along the combustor, flue gas leaving the turbine and compressed air leaving the compressor. For exhaust gas emission analysis MRU VARIO plus industrial infrared gas analyzer was used. The used gas analyzer has an accuracy of 0.02%, 5% and 5% for CO, NO and NO2 respectively. In order to test the effect of producer gas injection direction, the system was started on LPG which is the reference fuel, then a gradual replacement of LPG with a radially injected producer gas fuels was applied. After that, a similar test at same conditions were repeated for the axially producer gas injection.

Impact & Benefits

Improved Efficiency: Staged combustion allows for better control over the combustion process, leading to improved overall efficiency of the turbine. This is because it enables optimized fuel-air mixing and combustion, reducing energy losses and improving thermal efficiency.

Reduced Emissions: Producer gas, often derived from biomass or waste materials, tends to have lower emissions compared to traditional fossil fuels like natural gas or diesel. Staged combustion further enhances this by ensuring more complete combustion and minimizing the formation of harmful pollutants such as nitrogen oxides (NOx) and particulate matter.

Fuel Flexibility: Operating in a dual fuel mode provides greater flexibility in fuel choice. The turbine can switch between producer gas and another fuel source, such as natural gas or diesel, based on availability, cost, or specific operational requirements. This flexibility enhances the resilience and adaptability of the turbine system.

Environmental Benefits: The use of producer gas, derived from renewable or waste sources, contributes to environmental sustainability by reducing reliance on fossil fuels and mitigating greenhouse gas emissions. Additionally, the lower emissions associated with staged combustion further minimize the environmental footprint of the turbine operation

Market Potential

Demand for Clean Energy Solutions: With increasing concerns about climate change and air pollution, there is a growing demand for cleaner and more sustainable energy solutions. Technologies that offer improved performance and reduced emissions, such as producer gas staged combustion in micro-gas turbines, are likely to find favor in markets where environmental regulations are stringent or where there is a strong emphasis on sustainability.

Energy Market Dynamics: The dynamics of the energy market, including fluctuations in fuel prices and availability, can impact the attractiveness of technologies like dual fuel micro-gas turbines. Regions with volatile fuel markets or limited access to traditional fossil fuels may see greater demand for alternative fuel solutions like producer gas.

Industrial and Distributed Power Generation: Micro-gas turbines are often used in industrial and distributed power generation applications, where reliability, efficiency, and emissions control are key considerations. Industries seeking to reduce their carbon footprint or achieve energy independence may be particularly interested in technologies that offer improved performance and emissions characteristics.

Government Policies and Incentives: Government policies, such as subsidies, tax incentives, and emissions regulations, can significantly influence the adoption of cleaner energy technologies. Incentives aimed at promoting renewable energy sources or reducing greenhouse gas emissions may create favorable market conditions for dual fuel micro-gas turbines with producer gas staged combustion.