Incorporating Carbon Nanotubes in Nanocomposite Mixed-Matrix Membranes for Gas Separation: A Review

Author: Hilmi Mukhtar - May 2022

Abstract

Carbon nanotube (CNT) is a prominent material for gas separation due to its inherent smoothness of walls, allowing rapid transport of gases compared to other inorganic fillers. It also possesses high mechanical strength, enabling membranes to operate at high pressure. Although it has superior properties compared to other inorganic fillers, preparation of CNTs into a polymer matrix remains challenging due to the strong van der Waals forces of CNTs, which lead to agglomeration of CNTs. To utilize the full potential of CNTs, proper dispersion of CNTs must be addressed. In this paper, methods to improve the dispersion of CNTs using functionalization methods were discussed. Fabrication techniques for CNT mixed-matrix membrane (MMM) nanocomposites and their impact on gas separation performance were compared. This paper also reviewed the applications and potential of CNT MMMs in gas separation.

Methodology

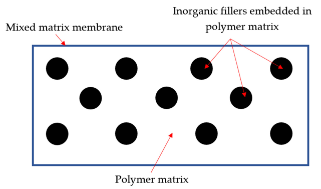

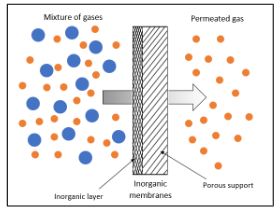

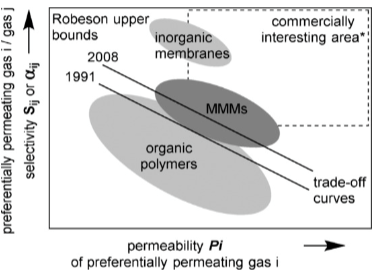

A mixed-matrix membrane is the dispersion of inorganic fillers at the nanometer scale within a polymer matrix to potentially resolve the trade-off relationship between permeability and selectivity. The addition of inorganic filler to the polymeric matrix improves gas diffusion and strengthens the physicochemical properties of MMMs. The primary goal of inorganic filler incorporation into the polymer matrix is to overcome the Robeson upper bound, which is related to the trade-off relationship between permeability and selectivity of different pairs of gases including CO2/CH 4, O2/N2, H 2/N 2,H 2/CH4, He/N 2, He/CH 4, H 2/CO2, He/H 2, and He/CO2. It was plotted using a log-log plot of pure gas permselectivity (Pi/Pj) versus Pi where P represents the polymer permeability, and i represents the more permeable gas pair i and j. As illustrated in Figure 4, inorganic membranes and MMMs can overcome the selectivity and permeability trade-off, attracting development for commercial purposes. With the limitation of an inorganic membrane in terms of economics, the approach of MMMs will be much more prominent in the future

Impact & Benefits

Prominence of Membrane Technologies:Membrane technologies have become prominent in gas processing applications, including nitrogen separation, natural gas purification, and hydrogen removal in petrochemical processes and refinery streams.

Advantages Over Other Separation Technologies:Membrane technologies offer benefits not provided by other separation technologies such as absorption, adsorption, and cryogenic methods.

Market Potential

Superior Performance Potential:The potential for superior performance suggests an opportunity for these membranes to address specific industry needs, potentially creating a niche market for applications where surpassing existing performance limits is crucial.

Dominance in Membrane Technology Research:The dominance of MMMs in research indicates a strong market potential, as these membranes are likely to be at the forefront of advancements and innovations in the membrane technology sector.