Interfacial Tailoring of Polyether Sulfone-Modified Silica Mixed Matrix Membranes for CO2 Separation

Author: Hilmi Mukhtar - November 2022

Abstract

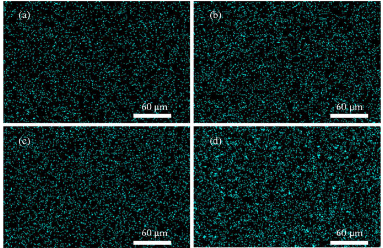

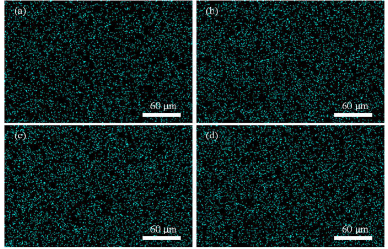

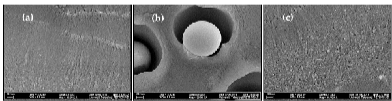

In this work, in situ polymerization of modified sol-gel silica in a polyether sulfone matrix is presented to control the interfacial defects in organic-inorganic composite membranes. Polyether sulfone polymer and modified silica are used as organic and inorganic components of mixed matrix membranes (MMM). The membranes were prepared with different loadings (2, 4, 6, and 8 wt.%) of modified and unmodified silica. The synthesized membranes were characterized using Field emission electron scanning microscopy, energy dispersive X-ray, Fourier transform infrared spectroscopy, thermogravimetric analyzer, and differential scanning calorimetry. The performance of the membranes was evaluated using a permeation cell set up at a relatively higher-pressure range (5-30 bar). The membranes appear to display ideal morphology with uniform distribution of particles, defect-free structure, and absence of interfacial defects such as voids and particle accumulations. Additionally, the CO2/CH4 selectivity of the membrane increased with the increase in the modified silica content. Further comparison of the performance indicates that PES/modified silica MMMs show a promising feature of commercially attractive membranes. Therefore, tailoring the interfacial morphology of the membrane results in enhanced properties and improved CO2 separation performance.

Methodology

The heating value of a material can be expressed in either lower (LHV) or higher heating value (HHV). The former is obtained when the heat of the combustion of the sample was determined relative to gaseous water while the latter is obtained when the product of the heat of combustion of the sample was determined relative to liquid water. The between the two values gives the latent heat of the product water. In the given study, the Leco AC-350 bomb calorimeter was used for the determination of heating values

Impact & Benefits

The permeability of CO2 and CH4 gases increases with the addition of silica loading in Mixed Matrix Membranes (MMMs)

Understanding the impact of silica loading provides insights into the tunability of gas permeability in MMMs. This knowledge is crucial for tailoring membrane properties for specific applications, such as gas separation or filtration.

The text highlights that, unlike unmodified silica-filled MMMs, the rise in permeability for CO2 and CH4 gases is not as sharp in MMMs with modified silica. This is attributed to the elimination of interfacial defects and voids in PES/modified silica MMMs due to good adhesion between the filler and the polymer.

The use of modified silica appears to enhance the structural integrity of MMMs, reducing defects and improving gas permeation control. This is valuable for creating more efficient membranes with controlled permeability.

Market Potential

Commercially Attractive Region: The positioning of PES/modified silica MMMs in the commercially attractive region suggests a potential market for these membranes in various applications, particularly in CO2 capture and natural gas processing.

Application in Natural Gas Processing:The recognition of these membranes as suitable for natural gas processing indicates a potential market niche. The membranes may find applications in gas separation and purification processes within the natural gas industry.