Modeling of Nitrogen Removal from Natural Gas in Rotating Packed Bed Using Artificial Neural Networks

Author: Azmi Shariff - July 2023

Amiza Surmi, Serene Sow Mun Lock

Abstract

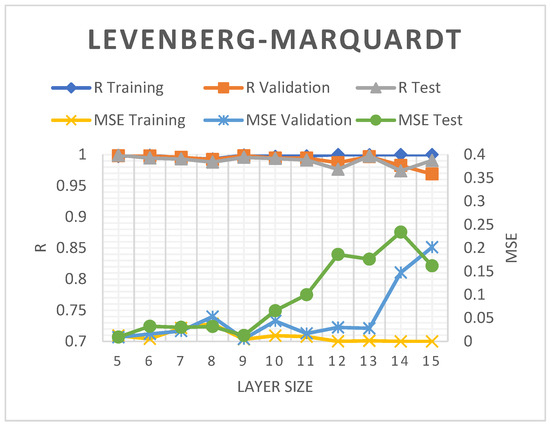

Novel or unconventional technologies are critical to providing cost-competitive natural gas supplies to meet rising demands and provide more opportunities to develop low-quality gas fields with high contaminants, including high carbon dioxide (CO2) fields. High nitrogen concentrations that reduce the heating value of gaseous products are typically associated with high CO2 fields. Consequently, removing nitrogen is essential for meeting customers' requirements. The intensification approach with a rotating packed bed (RPB) demonstrated considerable potential to remove nitrogen from natural gas under cryogenic conditions. Moreover, the process significantly reduces the equipment size compared to the conventional distillation column, thus making it more economical. The prediction model developed in this study employed artificial neural networks (ANN) based on data from in-house experiments due to a lack of available data. The ANN model is preferred as it offers easy processing of large amounts of data, even for more complex processes, compared to developing the first principal mathematical model, which requires numerous assumptions and might be associated with lumped components in the kinetic model. Backpropagation algorithms for ANN Lavenberg-Marquardt (LM), scaled conjugate gradient (SCG), and Bayesian regularisation (BR) were also utilised. Resultantly, the LM produced the best model for predicting nitrogen removal from natural gas compared to other ANN models with a layer size of nine, with a 99.56% regression (R2) and 0.0128 mean standard error (MSE).

Methodology

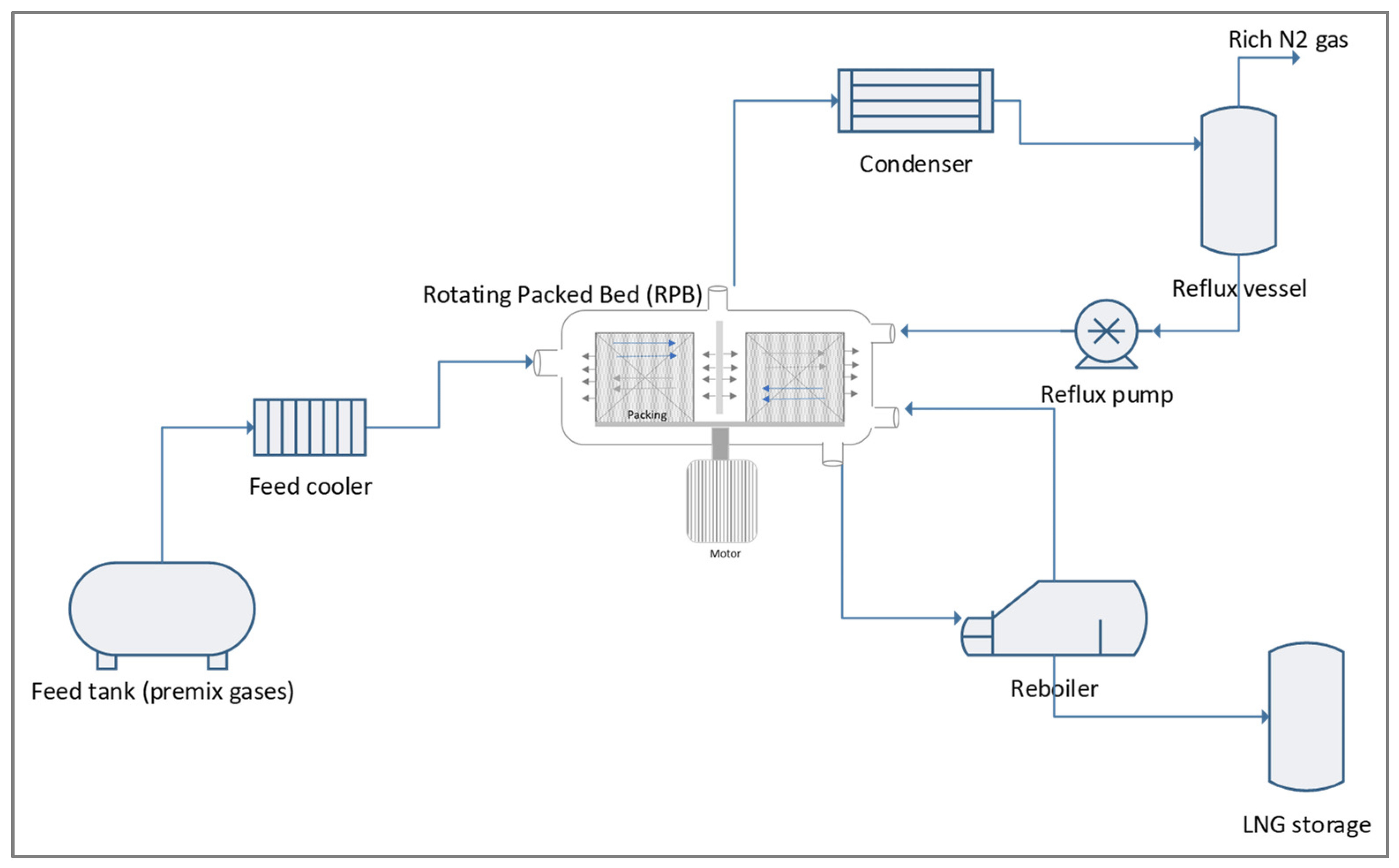

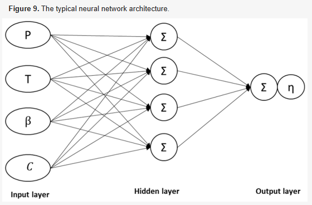

The study aimed to develop predictive models for nitrogen removal from natural gas using a rotating packed bed (RPB) and artificial neural networks (ANN). The experimental setup for nitrogen removal from natural gas using a rotating packed bed (RPB) under cryogenic conditions involved introducing natural gas with up to 20 mol% nitrogen concentration into a cryogenic distillation-RPB system pre-chilled to -120°C. The system utilized a liquid distributor to create a spray effect, enhancing mass transfer efficiency. The RPB operated in a counter-current manner, with the rich nitrogen discharged as a gas phase and liquefied natural gas (LNG) obtained as the bottom product at -161°C. Experimental data collected were used to train the ANN models, which included three layers (input, hidden, output) and utilized training algorithms such as Levenberg-Marquardt (LM), Bayesian regularisation (BR), and scaled conjugate gradient (SCG). The models were evaluated based on regression rate (R²) and mean standard error (MSE), with MATLAB (R2022a) used for analysis. Process parameters like pressure, temperature, and concentration were varied to optimize nitrogen removal efficiency

Impact & Benefits

Cost Saving: The development of accurate predictive models for nitrogen removal in natural gas processing can lead to cost savings by optimizing process parameters and reducing energy consumption.

Process Efficiency: By utilizing artificial neural networks to predict nitrogen removal efficiency, the study enables the enhancement of process efficiency, resulting in higher yields of purified natural gas products.

Competitiveness: The ability to remove nitrogen effectively from natural gas under cryogenic conditions can enhance the competitiveness of natural gas suppliers by meeting customer requirements for high-quality gas products.

Potential of Techno-Economic Studies: The research provides a valuable tool for conducting techno-economic studies, allowing for the assessment of the economic viability and feasibility of nitrogen removal processes in natural gas production.

Comercialization Opportunities: The reliable predictive models developed in this study can facilitate the scaling up of technologies for commercialization, opening up opportunities for the implementation of novel nitrogen removal processes in industrial settings.

Findings/Figures and Research Data

Efficient Nitrogen Removal: The study demonstrated that the RPB under cryogenic conditions showed considerable potential for efficiently removing nitrogen from natural gas, achieving a nitrogen removal efficiency above 97% under high gravity factor conditions (30 to 90).

Reduced Equipment Size: The use of RPB for nitrogen removal was found to significantly reduce the equipment size compared to conventional distillation columns, leading to more economical and efficient nitrogen removal processes.

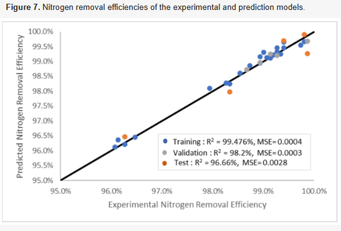

Optimal ANN Model: Among the ANN models tested, the Levenberg-Marquardt (LM) model was identified as the most effective for predicting nitrogen removal efficiency, with a high regression rate (R²) of 99.56% and low mean standard error (MSE) of 0.0128.

Market Potential

By developing accurate predictive models based on experimental data, this research offers a valuable tool for optimizing nitrogen removal processes, conducting techno-economic studies, and scaling up technologies for commercialization. The ability to reliably predict nitrogen removal efficiency can lead to cost savings, improved process efficiency, and enhanced competitiveness in providing high-quality natural gas products to meet increasing market demands.