Inherently safer process route ranking index (ISPRRI) for sustainable process design

Author: Azmi Shariff - December 2022

Muhammad Athar, Azizul Buang, Asim Umer - Muhammad Nawaz Sharif, Dzulkarnain Zaini

Abstract

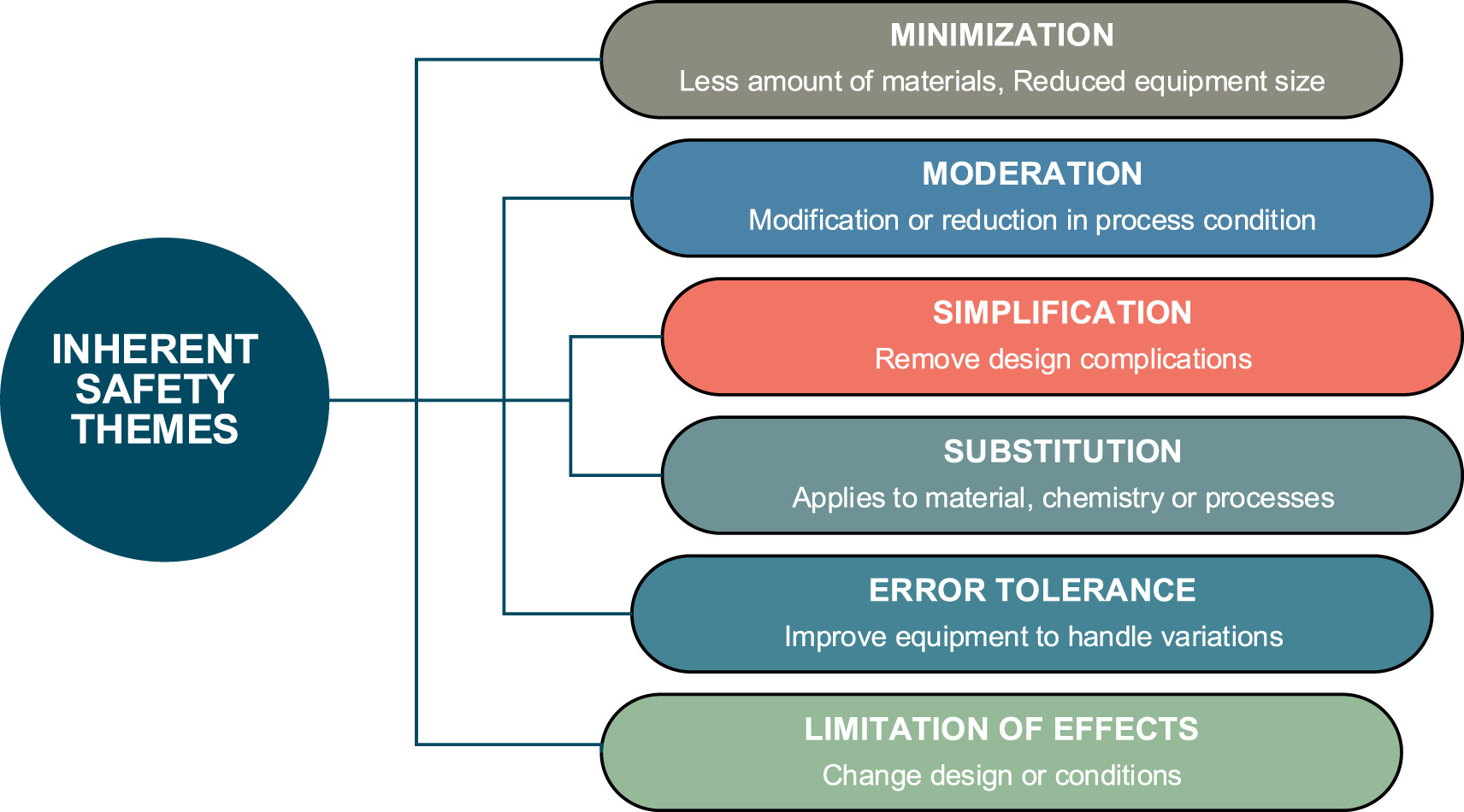

The growth of process industries has escalated the probability of loss containment scenarios of hazardous ma terials that can be tackled via process safety schemes. For preliminary design stage, the inherent scheme is more promising to generate sustainable process designs. For this purpose, various process routes are typically compared to recognize the safer one via numerous indexing methods to eliminate routes with hazardous ma terials. However, these indices lack in accommodating the equipment characteristics and the underutilization of process and chemical characteristics. Specifically for chemical characteristics, the toxicity aspect has not been engaged for process route selection in conjuction with other aspects. Consequently, an advanced indexing method is consolidated in the present work for the mentioned gaps named as inherently safer process route ranking index (ISPRRI). This method utilizes the equipment, chemical, and process aspects for ranking purposes. MMA process routes have been studied with the proposed method, and the obtained results validate the appli cability to identify the less hazardous route and are in agreement with previous indices. The technique would facilitate the design engineers to rigorously compare the process routes to highlight the inherently safer route with less hazardous materials for the desired chemical product.

Methodology

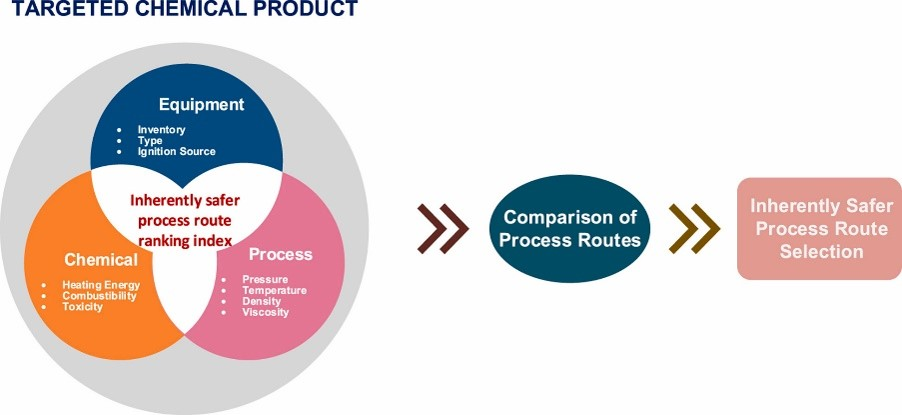

In this study, Inherently Safer Process Route Ranking Index (ISPRRI) method was applied for sustainable methyl methacrylate (MMA) production process design. The ISPRRI method was designed to compare different process routes based on inherent safety and sustainability criteria, aiming to promote safer and more sustainable process designs in the chemical industry. The selection of process routes includes the use of methyl propionate (C2MP), ethylene through propionaldehyde (C2PA), isobutylene (i-C4), and tertiary butyl alcohol (TBA) to produce MMA. ISPRRI method was achieved through a systematic approach that integrates equipment, chemical, and process aspects to rank different process routes for sustainable design. MS Excel and ASPEN HYSYS softwares were utilzed to collect and process information for route comparison. By considering various factors such as explosion potential, toxicity, process conditions, equipment characteristics, and other relevant variables, the ISPRRI calculated an index value for each route. A lower ISPRRI value indicated a route with less hazardous materials, making it inherently safer for the desired chemical product. This approach allows design engineers to identify the safest process route more effectively and promote sustainable process design

Impact & Benefits

Advancement in Process Safety: The development of the ISPRRI method contributes to advancing process safety strategies by providing a systematic approach to evaluate and compare process routes based on inherent safety criteria.

Enhanced Sustainability: The ISPRRI method promotes sustainability in process design by facilitating the selection of inherently safer process routes, which can lead to reduced risks associated with hazardous materials.

Improved Decision-Making: Design engineers can make more informed decisions at the preliminary design stage by using the ISPRRI method to identify the safest process route for a desired chemical product.

Validation of Previous Indices: The study validates the ISPRRI method against previously published indices, demonstrating its effectiveness in ranking process routes for methyl methacrylate (MMA) production.

Safer Process Designs: The ISPRRI method helps in identifying process routes with lower hazards, leading to the selection of inherently safer designs for chemical processes.

Efficient Route Comparison: By considering various factors such as toxicity, explosion potential, and process conditions, the ISPRRI method enables a more comprehensive and efficient comparison of different process routes.

Cost Savings: Selecting inherently safer process routes early in the design stage can potentially reduce costs associated with safety measures and risk mitigation strategies during operation.

Tool for Design Engineers: The ISPRRI method provides a valuable tool for design engineers to prioritize safety and sustainability aspects in the selection of process routes, ultimately contributing to improved process design outcomes.

Findings/Figures and Research Data

Development of ISPRRI Method: The study introduces the ISPRRI method as an advanced indexing technique that considers equipment, chemical, and process aspects for ranking process routes based on inherent safety criteria.

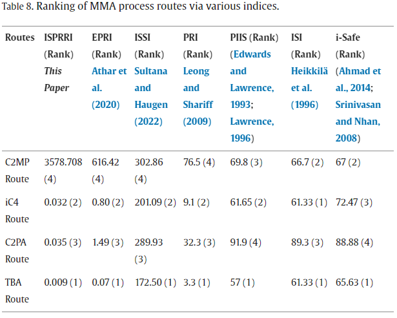

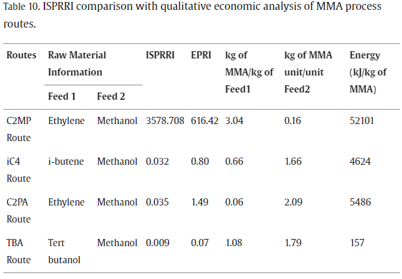

Validation with MMA Production: The ISPRRI method was applied to study process routes for methyl methacrylate (MMA) production, specifically comparing routes using ethylene through methyl propionate (C2MP), ethylene through propionaldehyde (C2PA), isobutylene (i-C4), and tertiary butyl alcohol (TBA).

Identification of Safer Route: The ISPRRI method successfully identified the inherently safer process route for MMA production, with the study recommending the use of TBA based on the ISPRRI values obtained.

Comparison With Previous Indices: The study validated the ISPRRI method by comparing its results with previously published indices, such as the Extended Process Route Index (EPRI), demonstrating consistency in identifying safer process routes.

Enhanced Process Safety: The ISPRRI method offers a comprehensive approach to evaluating process routes, considering factors like toxicity, explosion potential, and process conditions, to promote safer and more sustainable process designs.

Potential For Industry Application: The findings suggest that the ISPRRI method has the potential to be applied in industry settings to improve decision-making in process route selection, leading to enhanced safety and sustainability outcomes in chemical processing facilities."

Market Potential

ISPRRI presents a transformative opportunity within the chemical process industry, offering a systematic framework for evaluating process routes with a focus on safety and sustainability. By bolstering safety protocols, streamlining design efficiency, ensuring adherence to regulatory standards, and fostering cost-effective practices, ISPRRI empowers organizations to excel in the realm of safe and sustainable process design.