Mechanical earth modeling and sand onset production prediction for Well X in Malay Basin

Author: Shaharin Anwar Sulaiman - June 2020

Abstract

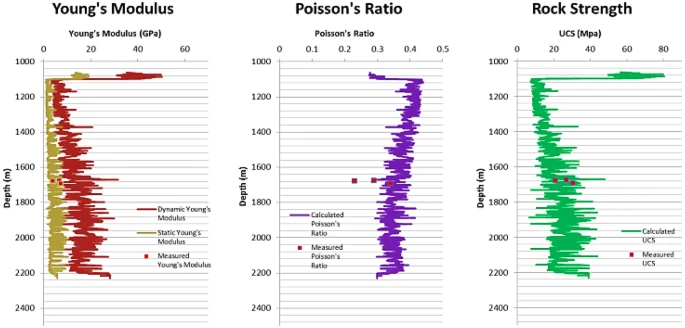

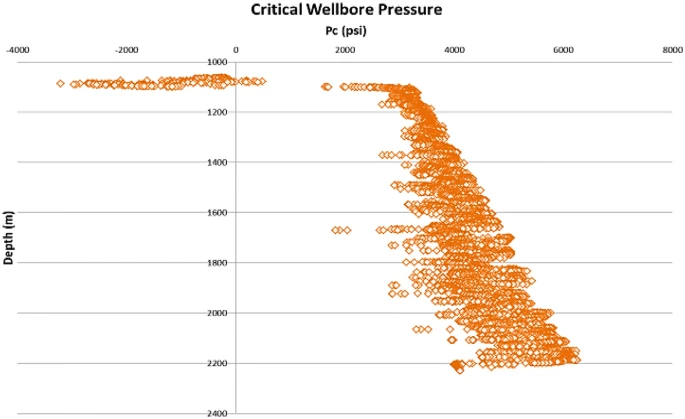

This study is aimed at testing Mechanical earth modeling (MEM) and Sand onset production prediction (SOP) models using well log and core data to estimate the mechanical properties of the rock, in-situ stresses and the critical conditions at which the rock failure may occur. New numerical models were developed to predict the onset of sand production for Well X. The outputs from MEM were coupled with the Mohr Coulomb failure criterion to calculate the critical wellbore pressure of the well and consequently the depth of the rock at which failure may occur. The results showed that at depth of 1061.68-1098.10 m, the calculated critical wellbore pressures were negatives, which reveal low possibility of sand production. However, at a depth of 1098.25-2230.89 m, the calculated critical wellbore pressures were positives. In this depth range, there was high possibility of rock failure. In conclusion, based on the findings, Well X may produce sand at depth deeper than 1100 m. Therefore, mitigation and preventive actions should be planned for Well X to handle and manage the possible sand production from the identified interval.

Methodology

MEM is a complete description of 1D state of in-situ stresses, rock mechanical properties (strength and deformation parameters, densities, etc.) and pore pressure for a continuous profile indexed to true vertical depth, TVD (Goodman and Connolly 2007). MEM is a collection of data measurements and models describing the mechanical properties of rocks and fractures, stresses, pressures and temperatures that operate on them at depth. Each MEM data point is referenced to its spatial co-ordinates and collection time. It has been acknowledged nowadays that dynamic elastic constants information with static equivalents, formation strength, and stresses prediction are critical to construct MEM. To provide a good mechanical earth model, all available data and indications of rock strength, deformity, pore pressure and in-situ stresses need to be integrated and analyzed thoroughly. Then this MEM will be calibrated as example for dynamic rock mechanical data with static test data using available core data measurements in order to arrive an internally consistent representation of the key geo-mechanical properties (Fattahpour et al. 2012). The results obtained can be applied for engineering designs and subsequent analysis, as in this study, it will be used for sand onset production prediction analysis. The following steps were taken to develop a MEM model:

Impact & Benefits

Improved Reservoir Understanding: MEM allows for a detailed characterization of the subsurface geology and reservoir properties. By incorporating geological, geophysical, and engineering data, MEM provides a comprehensive model of the reservoir, helping to understand its complexities and heterogeneities.

Enhanced Well Planning and Placement: With a better understanding of the reservoir, engineers can optimize well placement and trajectory to maximize production and minimize risks such as sand production. MEM provides insights into the reservoir structure, faults, fractures, and other geological features, aiding in the selection of optimal drilling locations.

Sand Onset Prediction: Sand production can cause significant operational challenges and damage to equipment. By predicting the onset of sand production using advanced modeling techniques, operators can take proactive measures to mitigate its effects. This may include adjusting production rates, installing sand control measures, or optimizing well designs to prevent sand influx into the wellbore.

Increased Production Efficiency: By accurately predicting sand onset and implementing appropriate mitigation strategies, operators can maintain stable production rates over the life of the well. This helps to maximize the ultimate recovery of hydrocarbons from the reservoir while minimizing costly production interruptions and equipment failures.

Market Potential

Growing Oil and Gas Industry: The Malay Basin is one of the key petroleum basins in Southeast Asia, with significant reserves of oil and gas. As the global demand for energy continues to rise, there is a continual need to maximize production from existing fields and develop new reserves. MEM and sand onset prediction offer solutions to optimize production and minimize operational risks in this dynamic market.

Technological Advancements: Advances in MEM technology, along with sophisticated algorithms for sand onset prediction, have improved the accuracy and reliability of reservoir characterization and production forecasting. This makes these techniques increasingly attractive to operators in the Malay Basin who seek to enhance their reservoir management practices and maximize recovery factors.

Cost Optimization: In today's competitive oil and gas market, operators are constantly seeking ways to optimize costs while maintaining or improving production efficiency. MEM and sand onset prediction can help achieve these objectives by enabling operators to make informed decisions regarding well placement, completion designs, and production strategies, ultimately leading to cost savings over the life of the asset.

Regulatory Compliance and Environment Concern: Regulatory requirements in the oil and gas industry are becoming more stringent, particularly concerning environmental protection and safety standards. Predicting and mitigating sand production can help operators comply with regulations and minimize the environmental impact of their operations, making MEM and sand onset prediction valuable tools for sustainable development in the Malay Basin.