Turbulence characteristics of the flexible circular cylinder agitator

Author: Shaharin Anwar Sulaiman - June 2021

Abstract

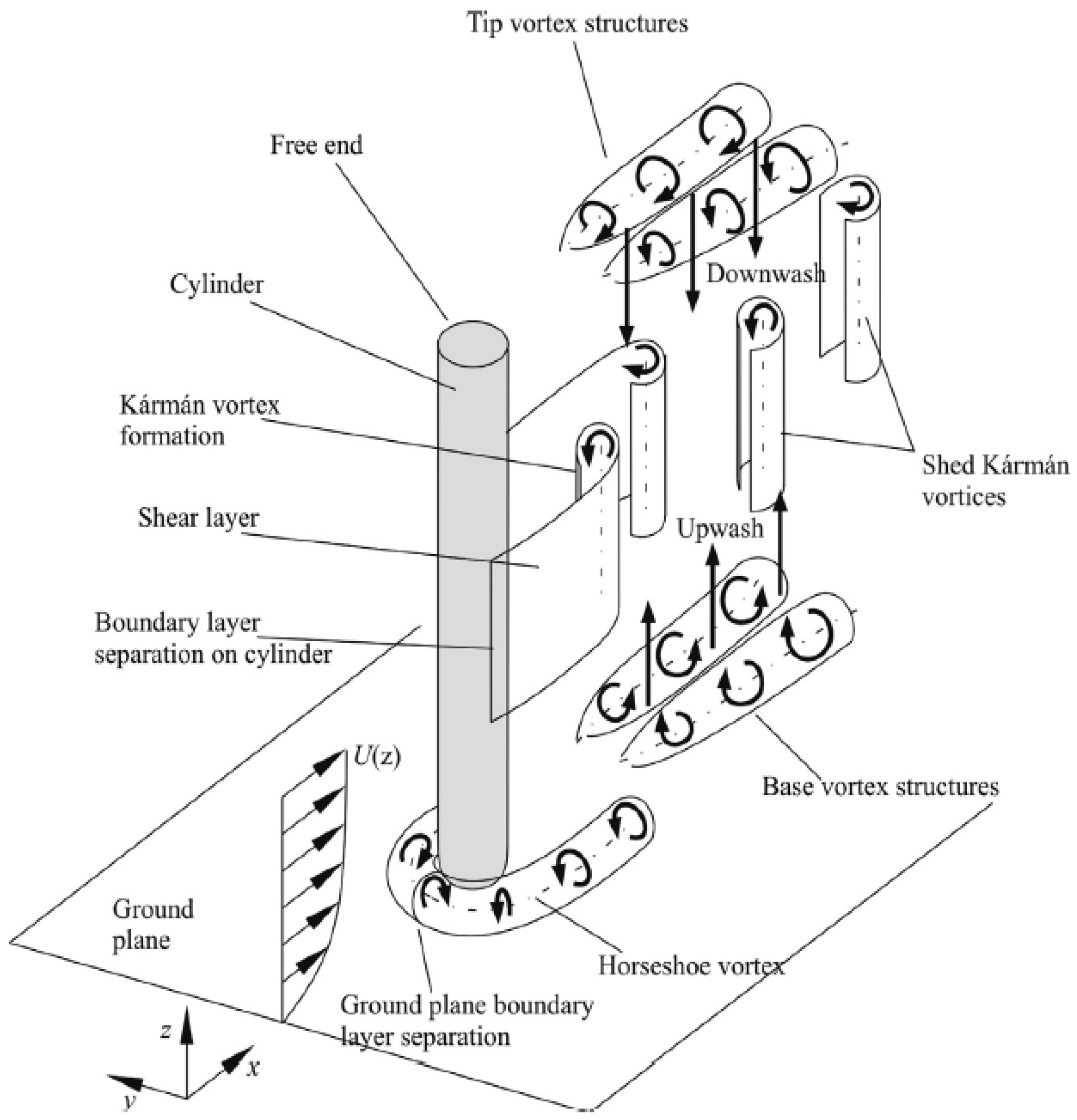

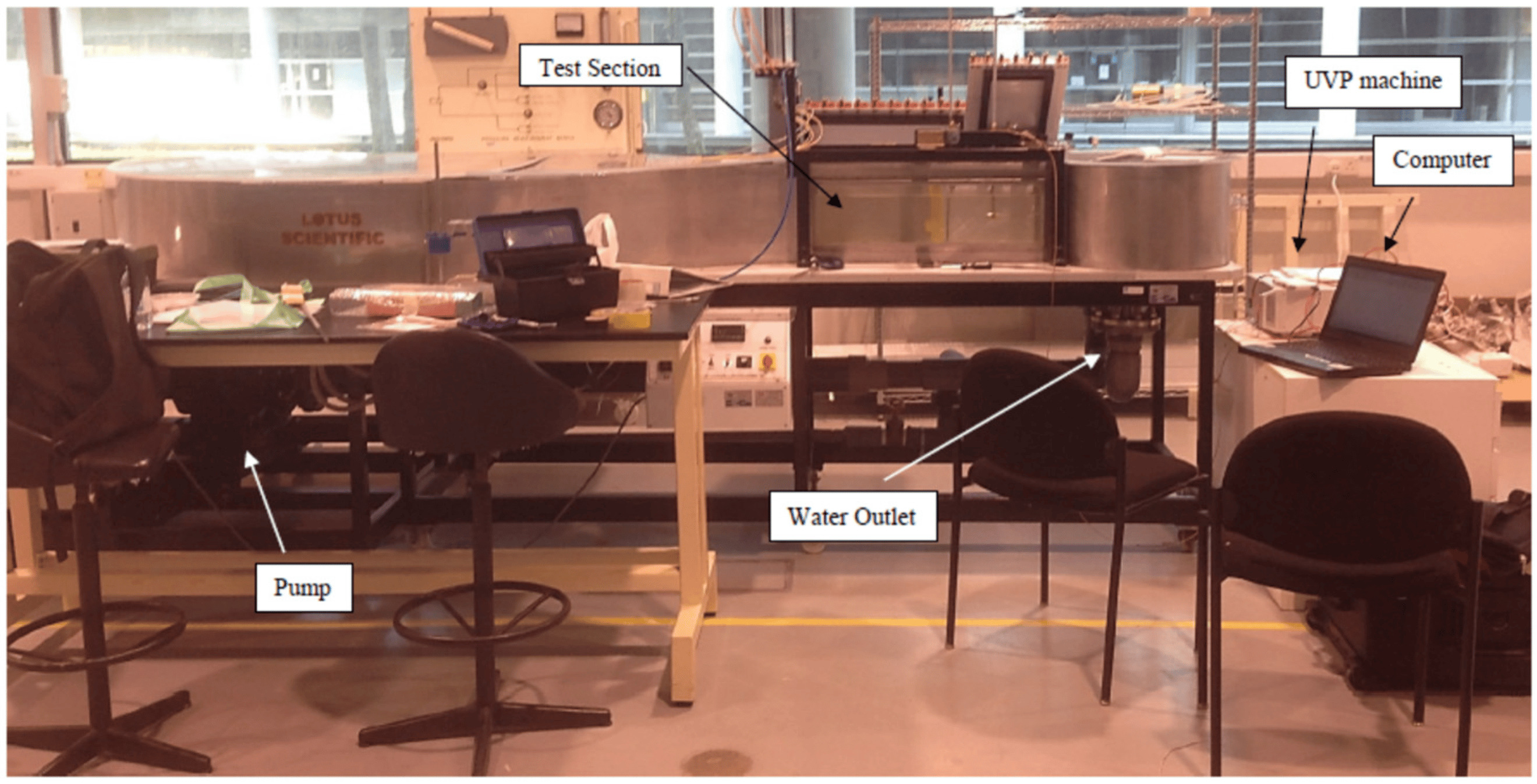

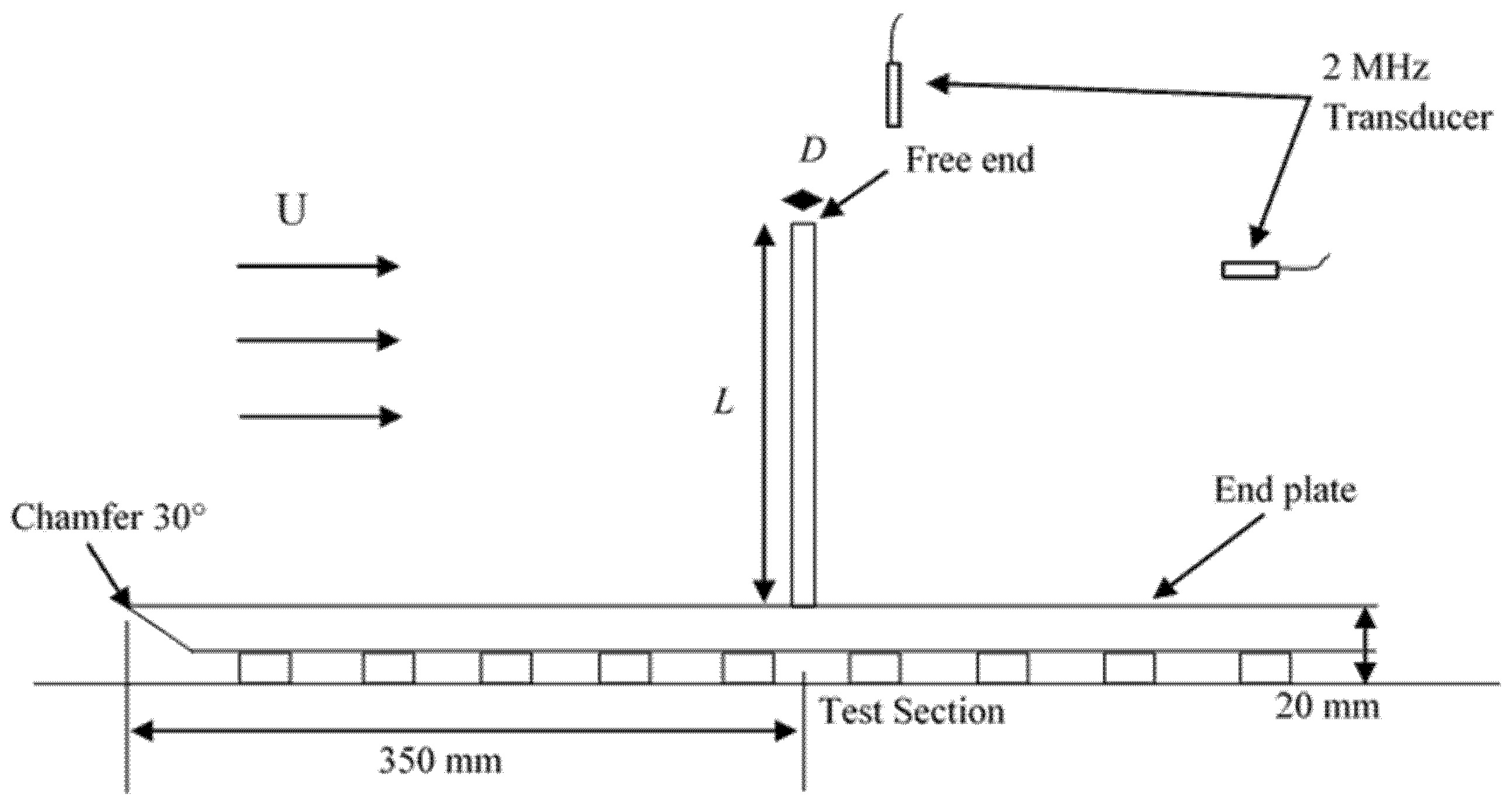

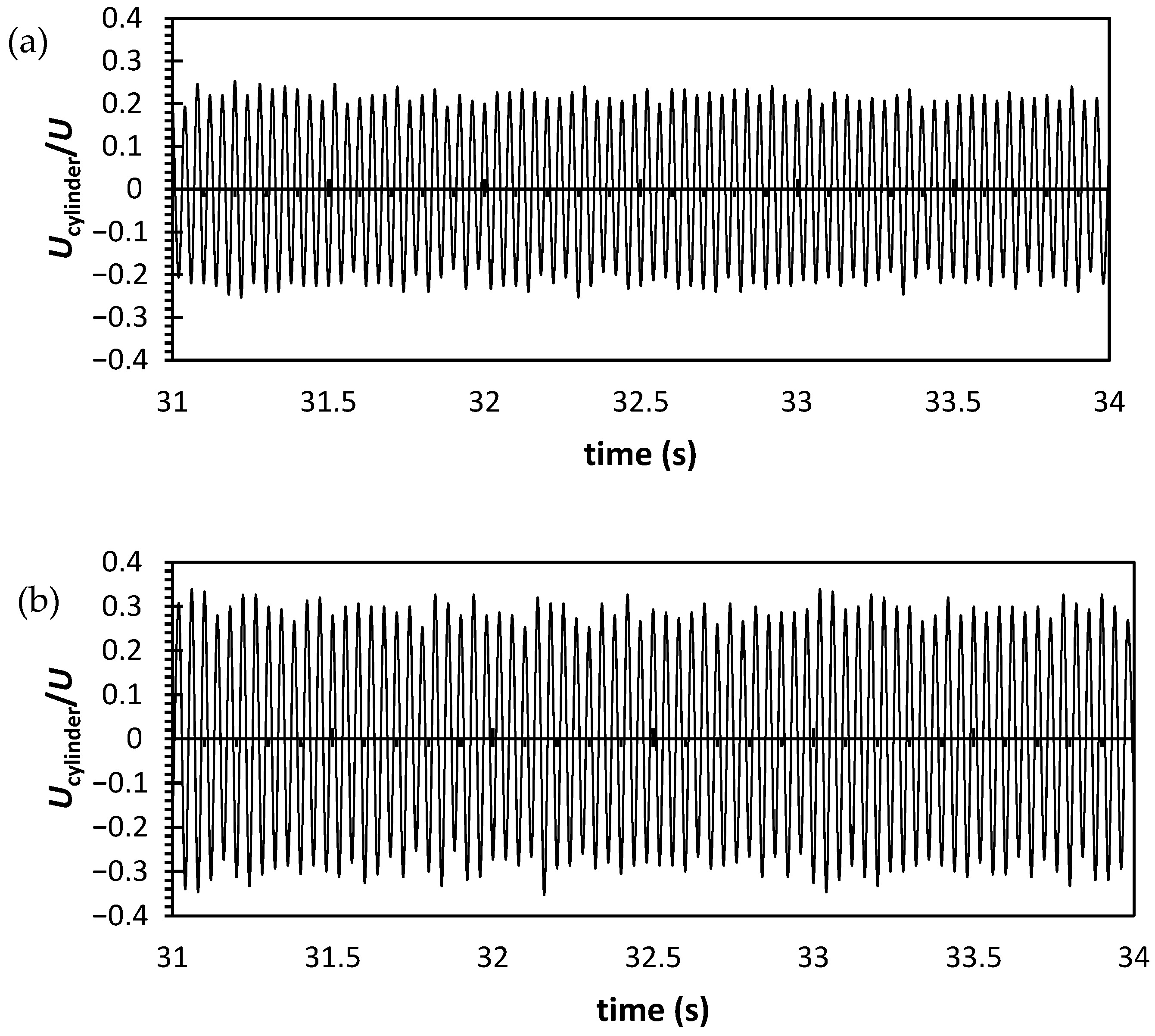

A flexible protruding surface was employed as the flow disturbance to promote turbulence at the area of interest. An ultrasonic velocity profiler, UVP technique, was used to study the mean and fluctuating flow properties in the near wake of the rigid and flexible protruding surface in a water tunnel. The polymer based, ethylene-vinyl acetate (EVA) with an aspect ratio of AR = 10, 12, 14, 16 was used as the flexible circular cylinder, and submerged in a flow at Re = 4000, 6000 and 8000. The motion of the cylinder altered the fluid flow significantly. As a means to quantify turbulence, the wakes regions and production terms were analyzed. In general, the flexible cylinders show better capability in augmenting the turbulence than the rigid cylinder. The results show that the turbulence production term generated by the flexible cylinder is higher than that of rigid cylinder. The localized maximum shear production values have increased significantly from 131%, 203% and 94% against their rigid counterparts of AR = 16 at the Re = 4000, 6000 and 8000, respectively. The performance of turbulence enhancement depends heavily on the motion of the cylinder. The findings suggest that the turbulence enhancement was due to the oscillation of the flexible cylinder. The results have concluded that the flexible cylinder is a better turbulence generator than the rigid cylinder, thus improving the mixing of fluid through augmented turbulent flow.

Methodology

The behavior of fluctuation quantities can be described by applying the Reynolds decomposition method to the Navier-Stokes equations and after a series of simplifications the kinetic energy budget which describes the energy of turbulence is formed. Since the kinetic energy budget provides insight on how the turbulence is distributed after being produced from the mean flow, there exists the kinetic energy budget for the mean flow and the kinetic energy budget for the turbulent flow, both of which compliment each other in the process of examining the transfer of turbulence energy.

Impact & Benefits

Enhanced Mixing Efficiency: Turbulence created by the flexible circular cylinder agitator helps in breaking down the boundary layers and promoting mixing of fluids. This leads to better dispersion of components and more uniformity in the mixture.

Improved Heat Transfer: Turbulence increases the rate of heat transfer between the agitated fluid and the surroundings, leading to more efficient cooling or heating processes.

Reduced Mixing Time: The turbulent flow generated by the agitator reduces the time required to achieve complete mixing, thereby increasing productivity and reducing processing time.

Better Mass Transfer: Turbulence enhances mass transfer rates by promoting the exchange of molecules between phases (e.g., gas-liquid or liquid-solid), which is crucial in processes like extraction, fermentation, and chemical reactions.

Market Potential

Industry Demand: Industries such as chemical processing, pharmaceuticals, food and beverage, biotechnology, cosmetics, and wastewater treatment heavily rely on mixing processes. The demand for advanced agitation technologies, including those offering optimized turbulence characteristics, remains robust within these sectors.

Regulatory Environment: Stringent regulatory requirements in industries like pharmaceuticals and food processing drive the need for efficient mixing processes that ensure product quality, consistency, and compliance with safety and quality standards. Agitators with superior turbulence characteristics can help meet these requirements.

Technological Advancements: As industries seek to improve process efficiency, reduce energy consumption, and enhance product quality, there is a growing interest in adopting advanced mixing technologies. Flexible circular cylinder agitators with customizable turbulence characteristics represent a technologically advanced solution that can cater to evolving industry needs.

Globalization and Industrialization: The increasing globalization and industrialization of emerging economies lead to the expansion of various manufacturing sectors. As these industries grow, the demand for efficient mixing equipment, including agitators with optimized turbulence characteristics, is expected to rise.