Experimental investigation of compressibility of waxy crude oil subjected to static cooling

Author: Shaharin Anwar Sulaiman - November 2019

Abstract

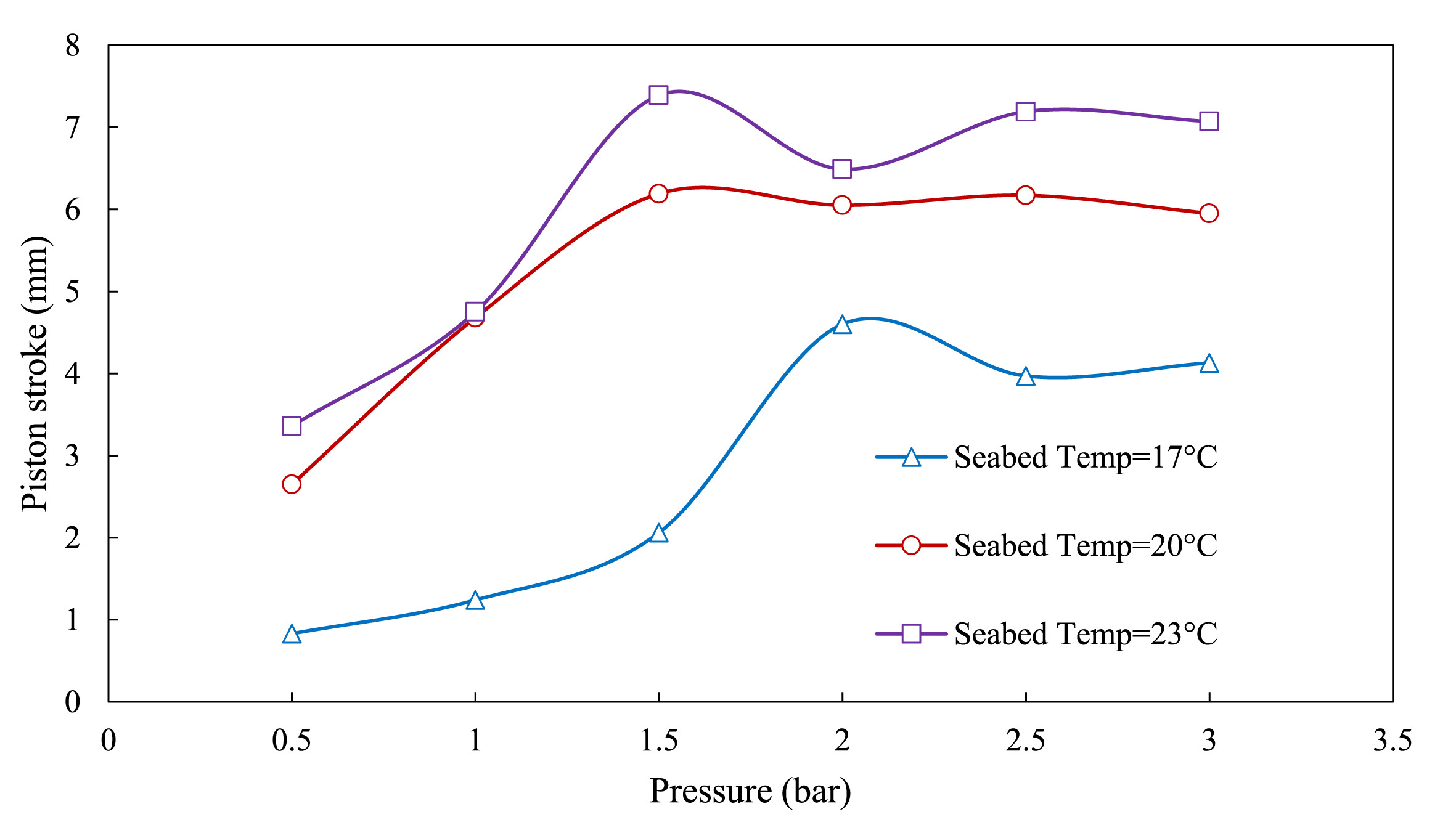

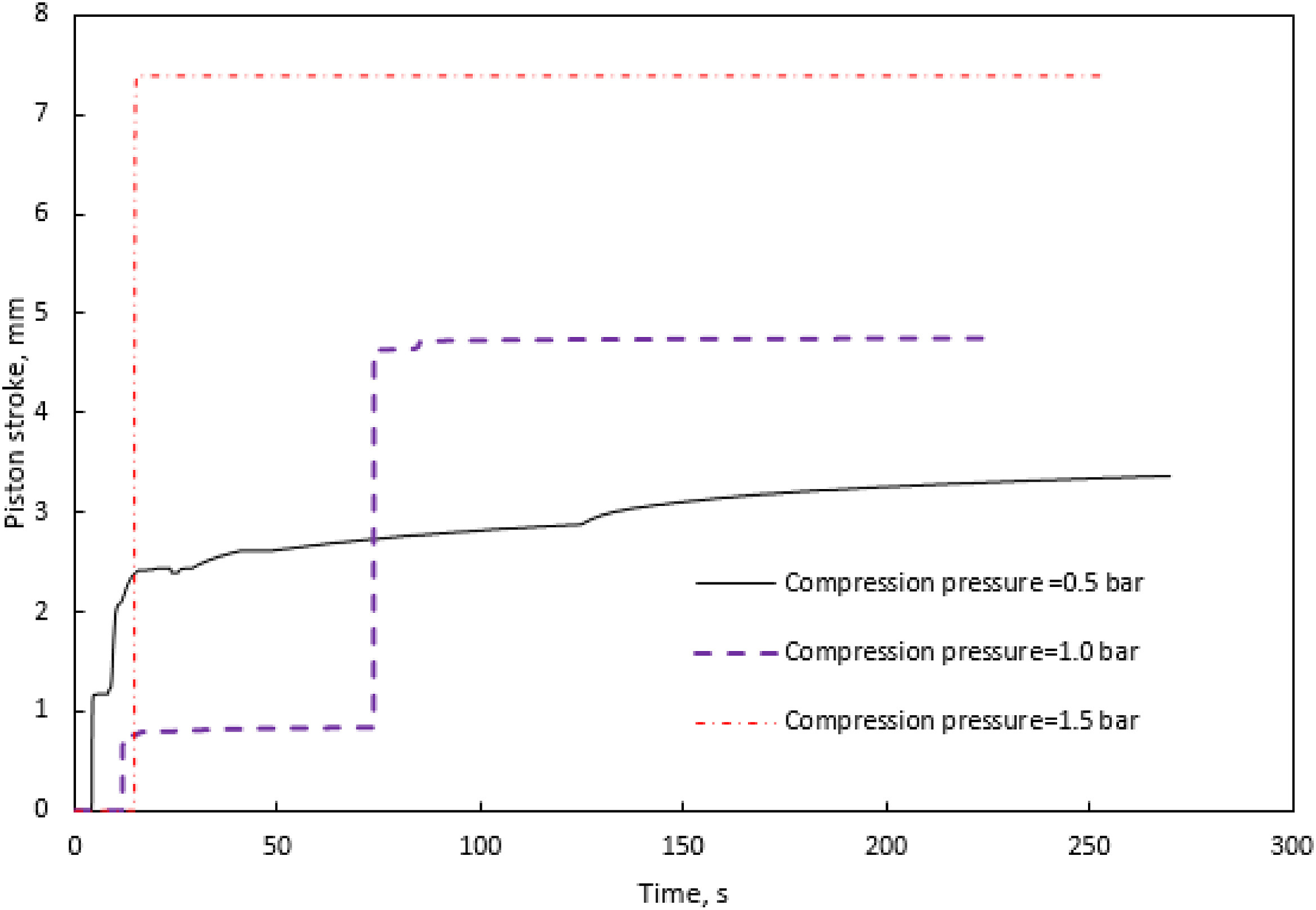

Transportation of waxy crude oil confronts many difficulties due to the formation of gel in the production pipelines, which interrupts the steady production with low transportation efficiency and this later requires a higher pumping pressure to resume the flow. However, the current conventional equation is perceived to be over-predicted, mainly due to low attention given for the compressibility effects. Compressibility of the waxy crude oil has been theoretically reported to have significant influence on the restart pressure of the flow start-up or restart. Moreover, there is limited study on compressibility of waxy crude oil induced by the formation of intra-gel voids as a result of thermal shrinkage encountered during static cooling. This study is, therefore, aimed at investigating the compressibility of waxy crude oil gel experimentally. The experiment included the use of flow loop rig to produce gel at different conditions. The pressure pump rig was designed and fabricated for the compressibility tests. Experiments were conducted at different cooling rates and seabed temperatures. It was observed that higher seabed temperature and slower cooling rates contribute to higher compressibility tendencies. The specimen with faster cooling rates is proven to be less compressible.

Methodology

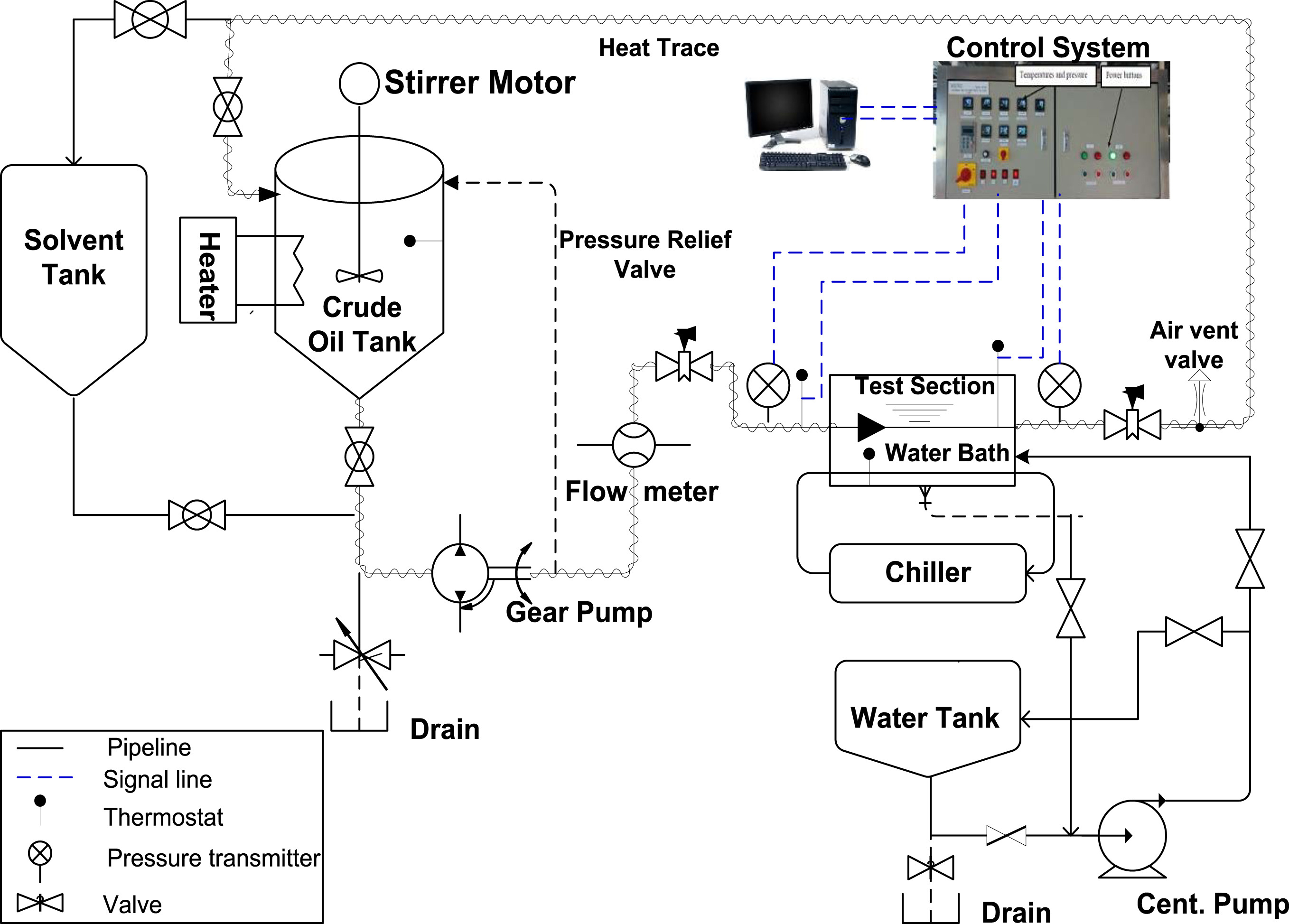

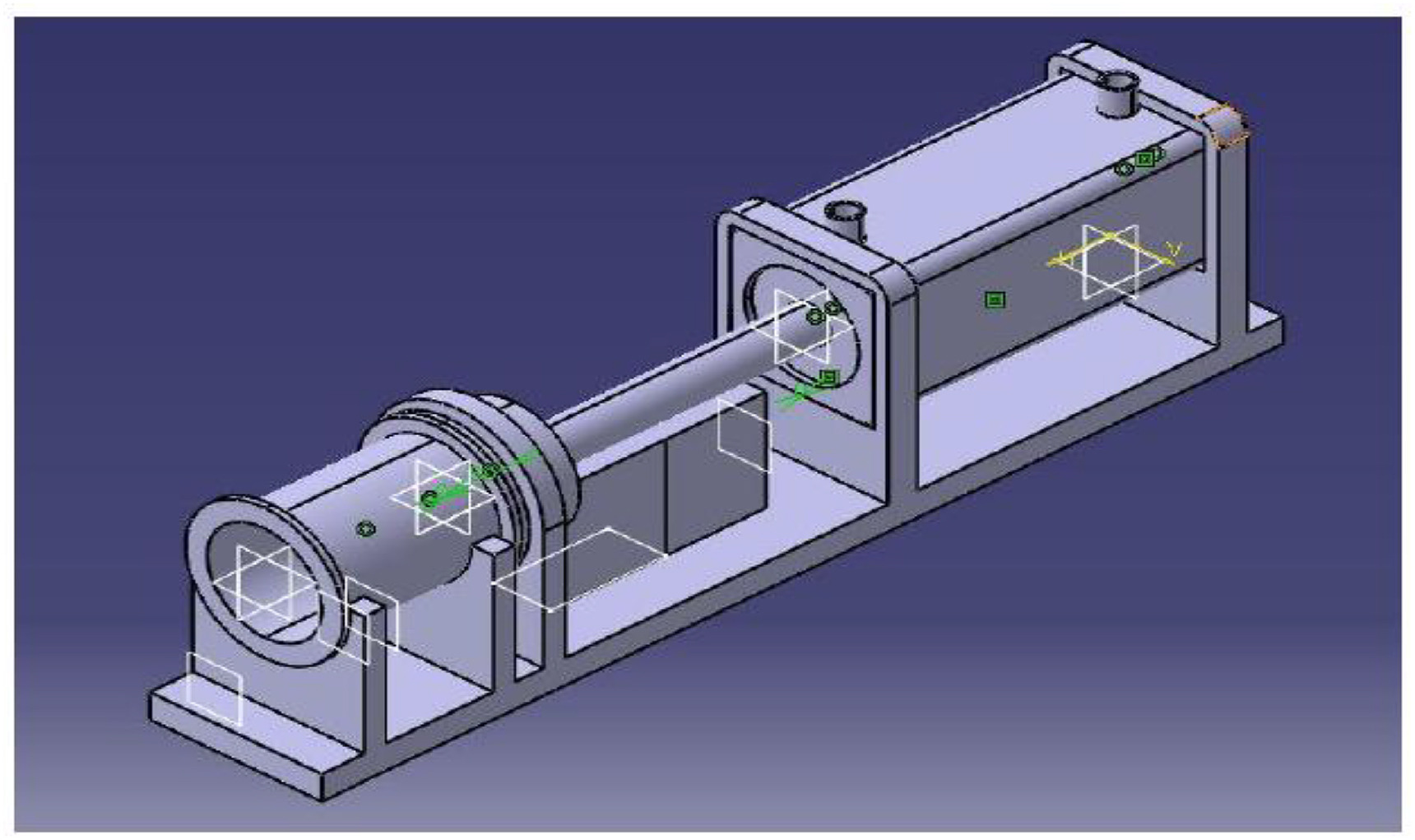

When the cold reservoir was fully filled and the test section pipe was fully immersed, the water line from the tank was cut and the flow of water was maintained in other line to homogenously cool the waxy crude oil inside the test section pipe and simulate subsea water. The incoming liquid crude oil was then pumped using the gear pump to restart the flow of gelled crude oil in the test section pipe. The sample was then left flowing for approximately 10 min to gain steady flow by removal of thermal and shear histories. The start temperature of the sample was made constant at 70°C, and this was well above the wax appearance temperature of the waxy crude oil used in this study which was 39.5°C as measured via a micro differential scanning calorimeter. Once the waxy crude temperature reached to 70°C, the gear pump was stopped to cool the sample in the test section statically to the set end temperatures. Subsequently, when reaching the end temperature, the test section in the cold reservoir was quickly detached from the flow loop rig for the compressibility tests. The test section attached with the stopper was then equipped on the pressure pump rig in such a way that it was parallel to the piston. The sensor and transducer were turned on and connected with the data acquisition system. The sensor was calibrated prior to taking measurement. The sensor is the small black rectangle installed beneath the piston cylinder. The thin film under the piston cylinder must always in contact with the sensor in order for it to detect the piston movement. After the pressure pump was set up and ready for taking compressibility test measurements, the one out of the ten test sections was taken out and equipped with gasket and stopper on one side to perform compressibility test. The sub-test section was then installed at the pressure pump rig in parallel with the piston cylinder device, and the support arm of the rig was tightened up to hold the test section. The readings of pressure versus time started simultaneously when the pressure from compressor was applied.

Impact & Benefits

Improved Understanding of Oil Behavior: This experimental investigation can provide insights into how waxy crude oil behaves when subjected to changes in temperature and pressure. Understanding the compressibility of oil is crucial for various industrial processes, including transportation, storage, and refining.

Optimization of Production Processes: By understanding the compressibility of waxy crude oil, production processes can be optimized to account for changes in volume and pressure. This optimization can lead to more efficient extraction, transportation, and storage of crude oil.

Enhanced Reservoir Management: Knowledge of oil compressibility can aid in reservoir management strategies. Understanding how oil volume changes with pressure can help in estimating reservoir size, predicting production rates, and designing optimal extraction methods.

Improved Pipeline and Storage Design: The compressibility of waxy crude oil influences the design and operation of pipelines and storage facilities. By understanding how oil volume changes under different conditions, engineers can design pipelines and storage tanks that can accommodate volume fluctuations without compromising safety or efficiency.

Market Potential

Oil Industry Demand: The oil industry is constantly seeking ways to optimize extraction, transportation, and refining processes to improve efficiency and reduce costs. Understanding the compressibility of waxy crude oil is crucial for this optimization, as it directly impacts various aspects of oil operations.

Regulatory Compliance: Regulatory bodies often impose strict guidelines and standards for the handling, transportation, and storage of crude oil. Research into oil compressibility can help companies meet these regulatory requirements more effectively, reducing the risk of fines and penalties.

Technological Advancements: As technology continues to advance, there is a growing need for more precise and accurate data on oil properties. Experimental investigations into oil compressibility can contribute to the development of advanced modeling and simulation tools that help companies better understand and predict oil behavior under different conditions.

Advancements in Research and Development: With increasing environmental awareness and regulations, there is a growing demand for sustainable and environmentally friendly practices in the oil industry. Research into oil compressibility can help companies minimize the risk of spills and leaks, thereby reducing their environmental impact.