Characterization of modified tapioca starch solutions and their sprays for high temperature coating applications

Author: Shaharin Anwar Sulaiman - January 2014

Abstract

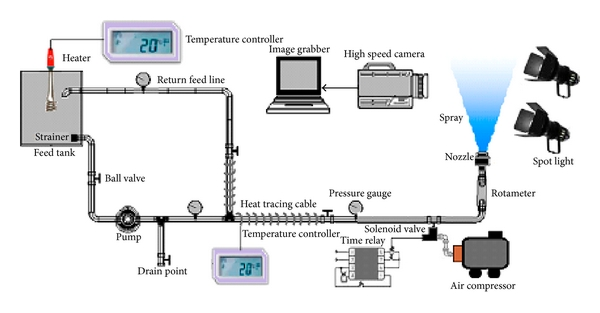

The objective of the research was to understand and improve the unusual physical and atomization properties of the complexes/adhesives derived from the tapioca starch by addition of borate and urea. The characterization of physical properties of the synthesized adhesives was carried out by determining the effect of temperature, shear rate, and mass concentration of thickener/stabilizer on the complex viscosity, density, and surface tension. In later stage, phenomenological analyses of spray jet breakup of heated complexes were performed in still air. Using a high speed digital camera, the jet breakup dynamics were visualized as a function of the system input parameters. The further analysis of the grabbed images confirmed the strong influence of the input processing parameters on full cone spray patternation. It was also predicted that the heated starch adhesive solutions generate a dispersed spray pattern by utilizing the partial evaporation of the spraying medium. Below 40 °C of heating temperature, the radial spray cone width and angle did not vary significantly with increasing Reynolds and Weber numbers at early injection phases leading to increased macroscopic spray propagation. The discharge coefficient, mean flow rate, and mean flow velocity were significantly influenced by the load pressure but less affected by the temperature.

Methodology

Three compositions of starch-urea-borate complex solution were prepared by following the procedure of Ariyanti et al. after some modifications. The composition of the materials in g/1000 mL of water is stated in Table 1. First of all, the tapioca starch was dried at 110°C for 2 hours in order to remove all the moisture contents or until no further weight transformations were noticed. The measured quantity of fully dried tapioca starch was put in a stainless steel iron-mixed container and dissolved in water. For complete gelatinization, the solution was reacted at 80°C for 30 minutes. The solution heating was carried out using a DIPO induction cooker (TCK35-E) equipped with a temperature sensor. An overhead stirrer (IKA-RW 20) was also used for stirring and uniform mixing of solution at 600 rpm. After 30 minutes, the known masses of urea (cross-linker) and borate (gelling agent) were added into starch dispersion. The solution was then heated further for 3 hours at a constant temperature of 80°C and rpm stirring. The final solution was left to cool to room temperature before further characterization.

Impact & Benefits

Improved Coating Performance: Understanding the characteristics of modified tapioca starch solutions can lead to the development of coatings that perform better under high-temperature conditions. This could include increased durability, resistance to thermal degradation, and better adhesion to substrates.

Cost-Effectiveness: Tapioca starch is often more cost-effective than synthetic polymers commonly used in coatings. Characterizing modified tapioca starch solutions can optimize their formulation, leading to more cost-effective coatings compared to traditional alternatives.

Environmental Benefits: Tapioca starch is a renewable and biodegradable resource, making coatings based on it more environmentally friendly compared to petroleum-based alternatives. Utilizing modified tapioca starch in coatings can contribute to reducing the environmental impact of coating applications.

Versatility: Tapioca starch can be modified in various ways to tailor its properties for specific applications. Characterization helps in understanding how different modifications affect the performance of tapioca starch-based coatings, thereby enhancing their versatility for a wide range of high-temperature applications.

Market Potential

Growing Demand for Sustainable Coatings: With increasing awareness of environmental issues and regulations promoting the use of eco-friendly materials, there is a growing demand for sustainable coatings. Tapioca starch-based coatings offer a renewable and biodegradable alternative to petroleum-based coatings, aligning with this trend.

Expansion of High-Temperature Application: High-temperature coating applications are prevalent across industries such as automotive, aerospace, marine, and industrial manufacturing. As these industries continue to grow and evolve, there is a rising need for coatings that can withstand extreme temperatures while providing durability and performance.

Shift Towards Bio-Based Materials: There is a global shift towards bio-based materials driven by concerns over environmental sustainability and the depletion of fossil resources. Modified tapioca starch solutions offer a viable bio-based alternative to synthetic polymers commonly used in coatings, catering to this growing demand for sustainable solutions.

Advancements in Research and Development: Ongoing research and development efforts aimed at improving the properties and performance of tapioca starch-based coatings are expanding the potential applications of these materials. Characterization studies play a crucial role in optimizing the formulations and understanding the behavior of these coatings under high-temperature conditions, driving further innovation in the field.