Comparative studies on catalytic and non-catalytic co-gasification of rubber seed shell and high density polyethylene mixtures

Author: Shaharin Anwar Sulaiman - May 2014

Abstract

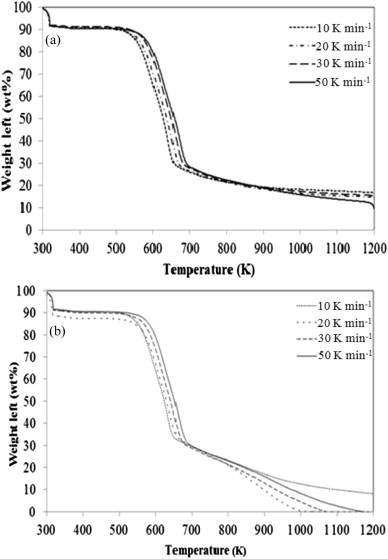

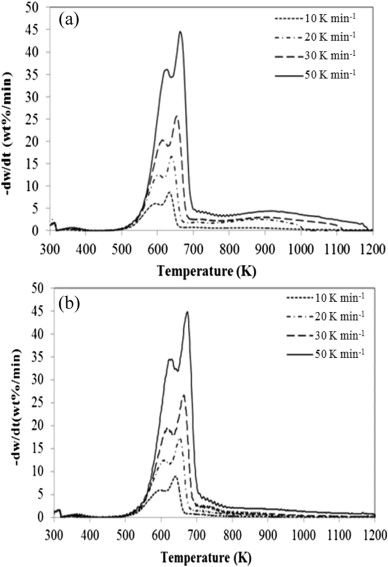

The thermal degradation behavior of rubber seed shell, high density polyethylene waste, and the binary mixtures of high density polyethylene and rubber seed shell (0.2:0.8 weight ratio) are compared in pyrolysis, gasification, and catalytic gasification process at different heating rate of 10, 20, 30 and 50 K min-1 in temperature range of 323-1173 K using thermogravimetric analysis equipment. It is observed that there are one, two, and three stages of decomposition occurring in high density polyethylene, rubber seed shell, and the binary mixtures respectively regardless of the process involved. The activation energies, EA and pre-exponential factor, A are generated using one step integral method based on first order rate of reaction. Besides that, the synergistic effect on the binary mixtures is also investigated for the three different processes involved. It is found that the EA and A values for the binary mixtures are lower than the pure high density polyethylene but comparable to pure rubber seed shell regardless of the processes involved. In addition, it is also observed that the EA and A values are slightly lower when catalyst is added in the binary mixtures compared to the absence of catalyst in the gasification process.

Methodology

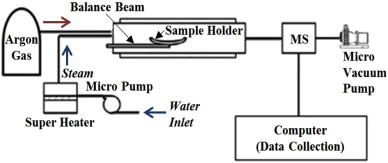

The experiments are performed using thermogravimetry analyzer EXSTAR TG/DTA 6300 (Seiko Instrument Inc.). Approximately 5 mg of sample is placed on a ceramic crucible in TGA under an inert atmosphere of argon. A flow rate of 100 mL min-1 of argon gas is fed into the system for 20 min at a temperature of 323 K. Subsequently, all samples are heated from 323 K to 1173 K at respective heating rates and temperatures are kept constant for 10 min. During heating, the TGA is used to measure mass variation of the materials and furnace temperature. Thermogravimetric curves are obtained at four heating rates (10, 20, 30, and 50 K min-1) within the temperature range of 323-1173 K. Steam is generated by a superheater at 383 K and is injected into the TGA at a flowrate of 300 µL h-1 when the temperature inside the TGA equipment reached to 383 K to avoid any occurrence of condensation within the system. The equivalence ratios (ER) for the pyrolysis and gasification process are 0 and 0.25 respectively. All experiments are repeated two or three times.

Impact & Benefits

Optimization of Co-Gasification Process: Comparative studies help in understanding how the presence of a catalyst affects the gasification process. This optimization can lead to improved efficiency, higher gas yields, and better utilization of feedstocks.

Synergistic Effects Identification: By comparing catalytic and non-catalytic processes, researchers can identify synergistic effects between the catalyst and the feedstock mixture. These effects can enhance gasification kinetics, increase gas quality, and lower the operating temperature.

Tailoring Gasification Products: Understanding the impact of catalysts allows for the tailoring of gasification products. For example, certain catalysts can promote the production of specific gases like hydrogen or methane, which are valuable for various industrial applications including fuel synthesis.

Environmental Benefits: Co-gasification of biomass and plastic waste offers environmental benefits such as reducing landfill waste and decreasing greenhouse gas emissions compared to conventional disposal methods like incineration.

Market Potential

Energy Demand and Sustainability:With growing concerns about climate change and the depletion of fossil fuel reserves, there is an increasing demand for sustainable energy sources. Co-gasification of biomass and plastic waste offers a renewable energy solution that can help meet this demand while reducing greenhouse gas emissions.

Waste Management Needs:The increasing generation of plastic waste, coupled with the need for effective waste management solutions, creates a market for technologies that can convert waste materials into valuable products like syngas or biofuels. Co-gasification presents an attractive option for diverting waste from landfills and reducing environmental pollution.

Regulatory Drivers:Stringent environmental regulations aimed at reducing carbon emissions and promoting renewable energy sources provide incentives for the adoption of co-gasification technologies. Governments may offer subsidies, tax incentives, or grants to support research and development in this area.

Market Opportunities for Synergas and Biofuels:Syngas produced from co-gasification can be used for various applications, including electricity generation, heat production, and synthesis of fuels and chemicals. Additionally, biofuels derived from biomass and plastic waste can find markets in transportation, industrial, and residential sectors.