Investigating the expansion characteristics of geopolymer cement samples in a water bath and compared with the expansion of ASTM Class-G cement

Author: Nasir Shafiq - February 2020

Abstract

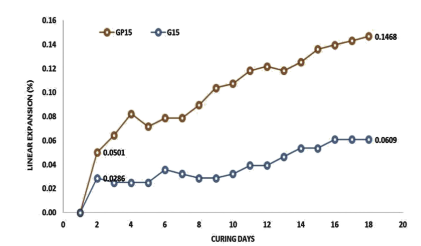

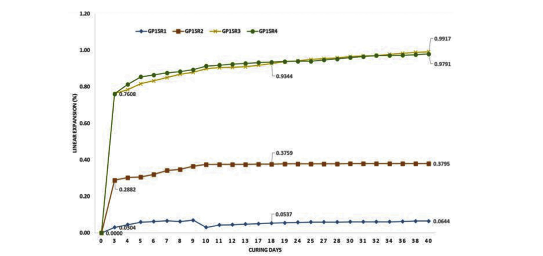

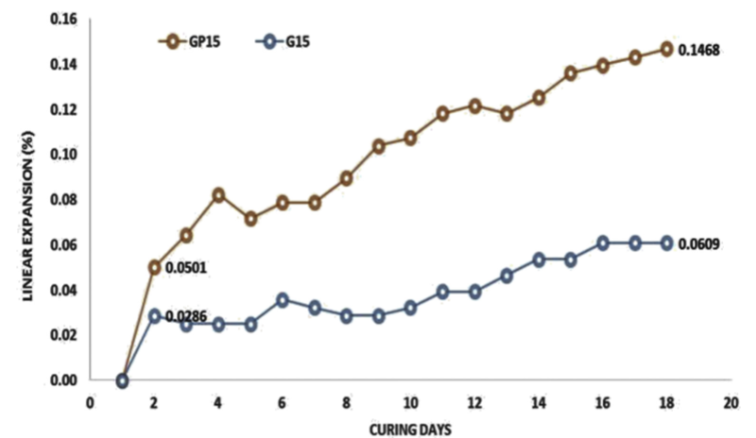

In selecting the binder composition for oil well application, its stability is an important design parameter. This paper presents the results of an experimental study conducted for comparing the linear expansion characteristics of geopolymer cement with the traditionally used ASTM Class G cement system. The expansion test was done in a water bath at 60 Celcius subjected to different curing intervals. The linear expansion of a cement system defines as the dimensional changes occur in the system, which is sometimes required to avoid the cement shrinkage during the hydration phase. In the case when the desired level of expansion is not achieved in the system, then the commercially available expandable materials are added in the class G cement system that enables the system to expand to the desired level. Shrinkage in the cementing system causes the formation of a microannulus or induces a gap that may allow the migration of fluid, hence the integrity of the system could be lost. This experimental study has revealed that the geopolymer cement tends to expand 0.15%-0.2% without the addition of any admixture, whereas the ASTM Class G cement has shown a lower value of linear expansion, which was obtained less than 0.1% after 18 days of curing. In the case of Class G cement, the addition of expandable material helped to increase the expansion; in the case of a geopolymer system, the additive has further accelerated the expansion.

Methodology

Portland cement class-G is generally used for for-well cementing, for which a necessary requirement is that it should be very low permeable. When the Portland cement is used in large volume such as for oil-well cementing, drying shrinkage may be a point of major concern for the integrity of the system. The drying shrinkage, as well as the brittle nature of Portland cement, increases the risk of cracking and hence the permeability of the system may be increased. Ultimately this type of deficiency of the system may cause the sealing failure. Therefore, to induce the ability of expansion in the system by adding some admixtures is considered one of the solutions for avoiding the sealing of the oil-well tubing system.

Impact & Benefits

Stability in Oil Well Application: The research investigates the linear expansion characteristics of geopolymer cement compared to ASTM Class G cement, emphasizing the importance of stability as a design parameter for oil well applications.

Addressing Cement Shrinkage: The significance of linear expansion in cement systems to prevent shrinkage during the hydration phase. Shrinkage could lead to the formation of microannulus or gaps, potentially compromising the integrity of the system and allowing fluid migration

Geopolymer Expansion Without Additives: The experimental results reveal that geopolymer cement exhibits a linear expansion of 0.15%-0.2% without the addition of any admixture. This suggests a natural expansion characteristic, potentially reducing the need for additional materials.

Understanding Class G Cement Expansion: The study indicates that ASTM Class G cement has a lower linear expansion (less than 0.1% after 18 days of curing). Understanding this behavior is crucial for oil well applications, and the research explores ways to enhance expansion, including the addition of expandable materials.

Market Potential

Geopolymer Cement Expansion without Additive: The conclusion that geopolymer cement has a reasonable tendency to expand without the mixing of an expansive material suggests a potential market for geopolymer cement as a standalone product with inherent expansion properties.

Optimization of Expansion: The impact of different additives on the expansion of geopolymer cement. This suggests a market potential for additives that can enhance and optimize the expansion characteristics of geopolymer cement, especially during the early stages of curing.

Demand for Expandable Materials: the addition of expandable materials, particularly elastomer-based ones, can improve both overall expansion and early expansion development. This suggests a market potential for expandable materials that can be used as additives in cement formulations, especially those designed for specific expansion requirements.